The document outlines the details of a student project to design and build a hovercraft. It includes:

- A list of project members and advisor.

- An overview of the contents and sections to be covered in the document, including introduction, history, design process, and conclusions.

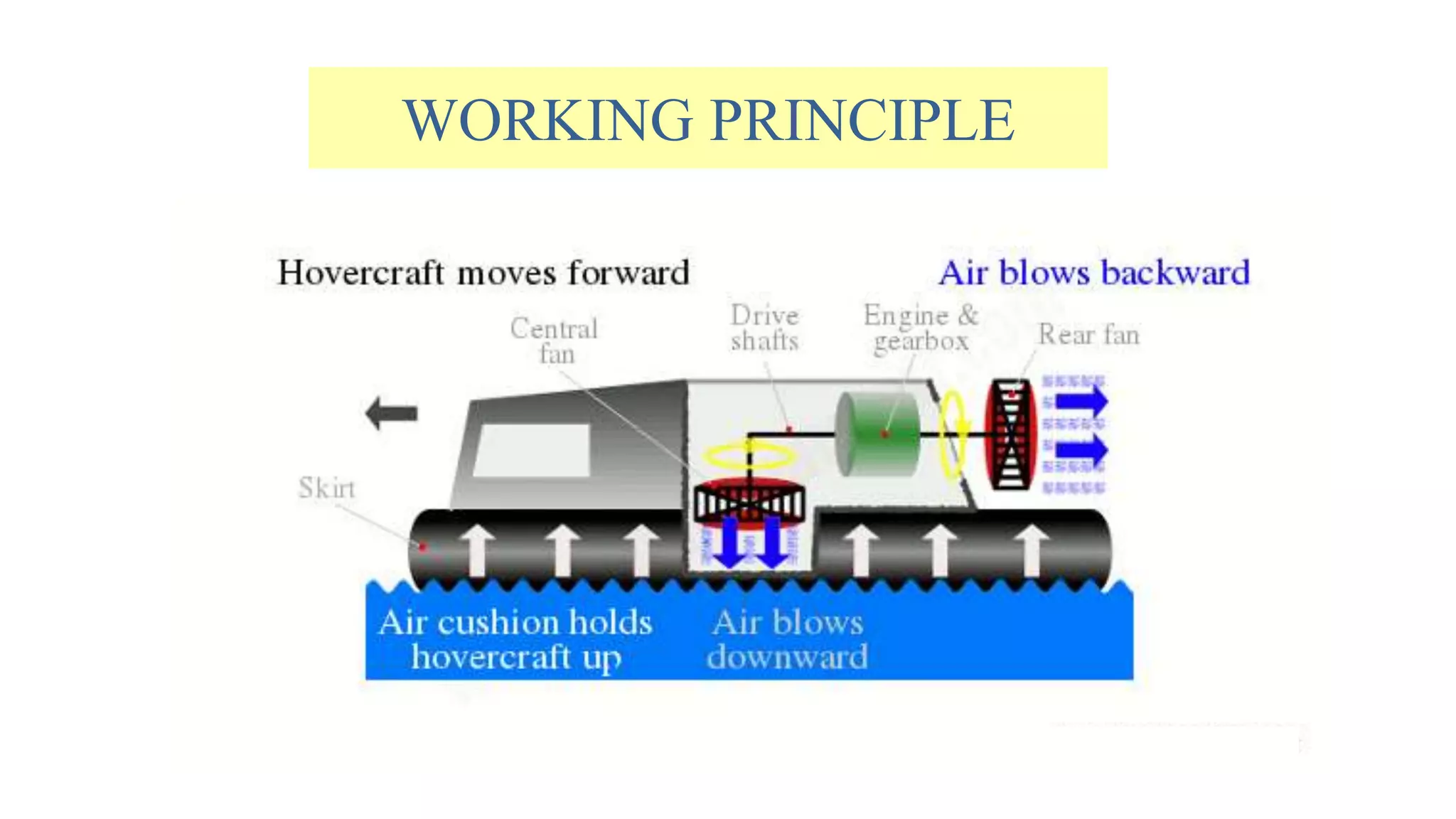

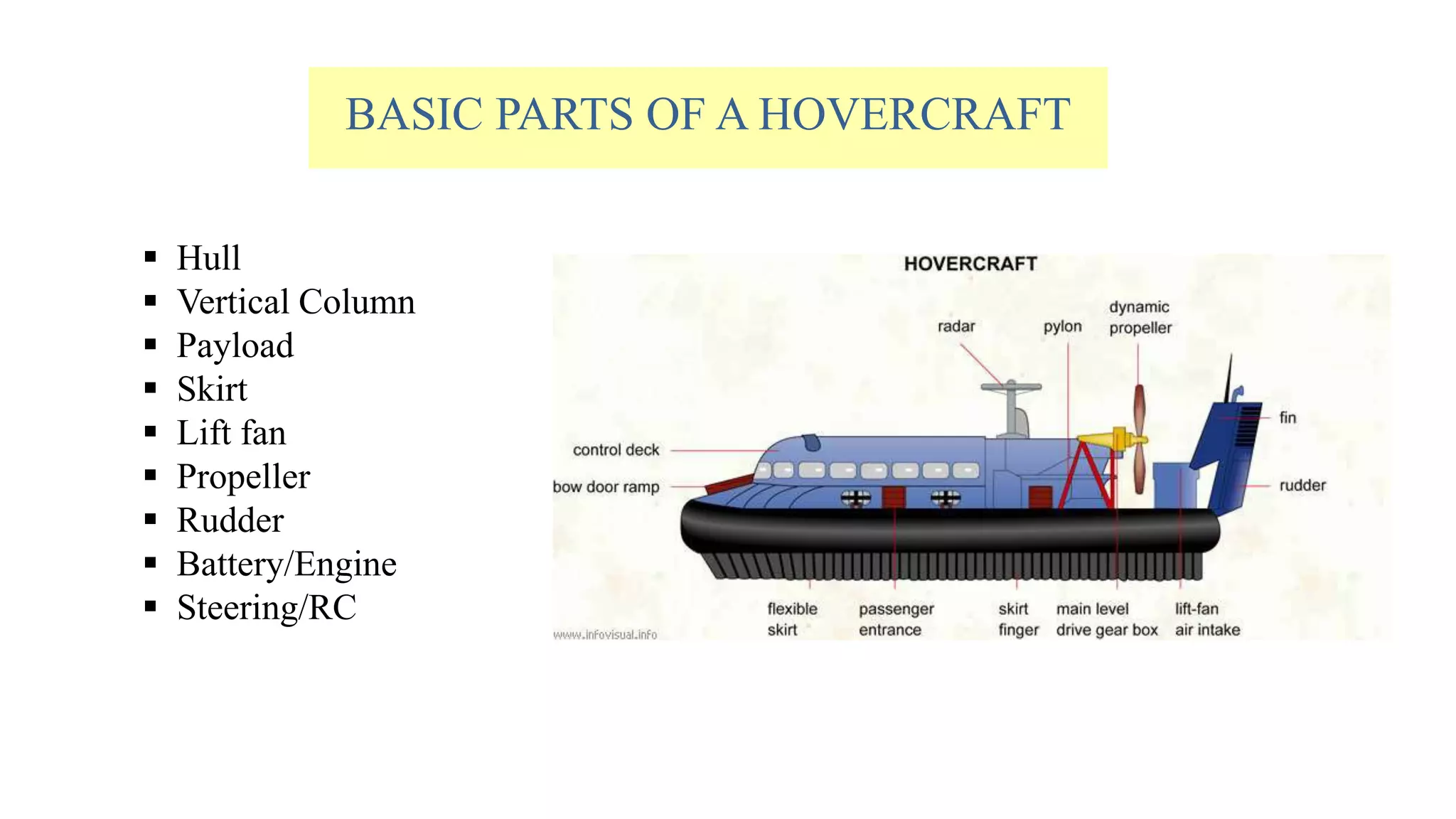

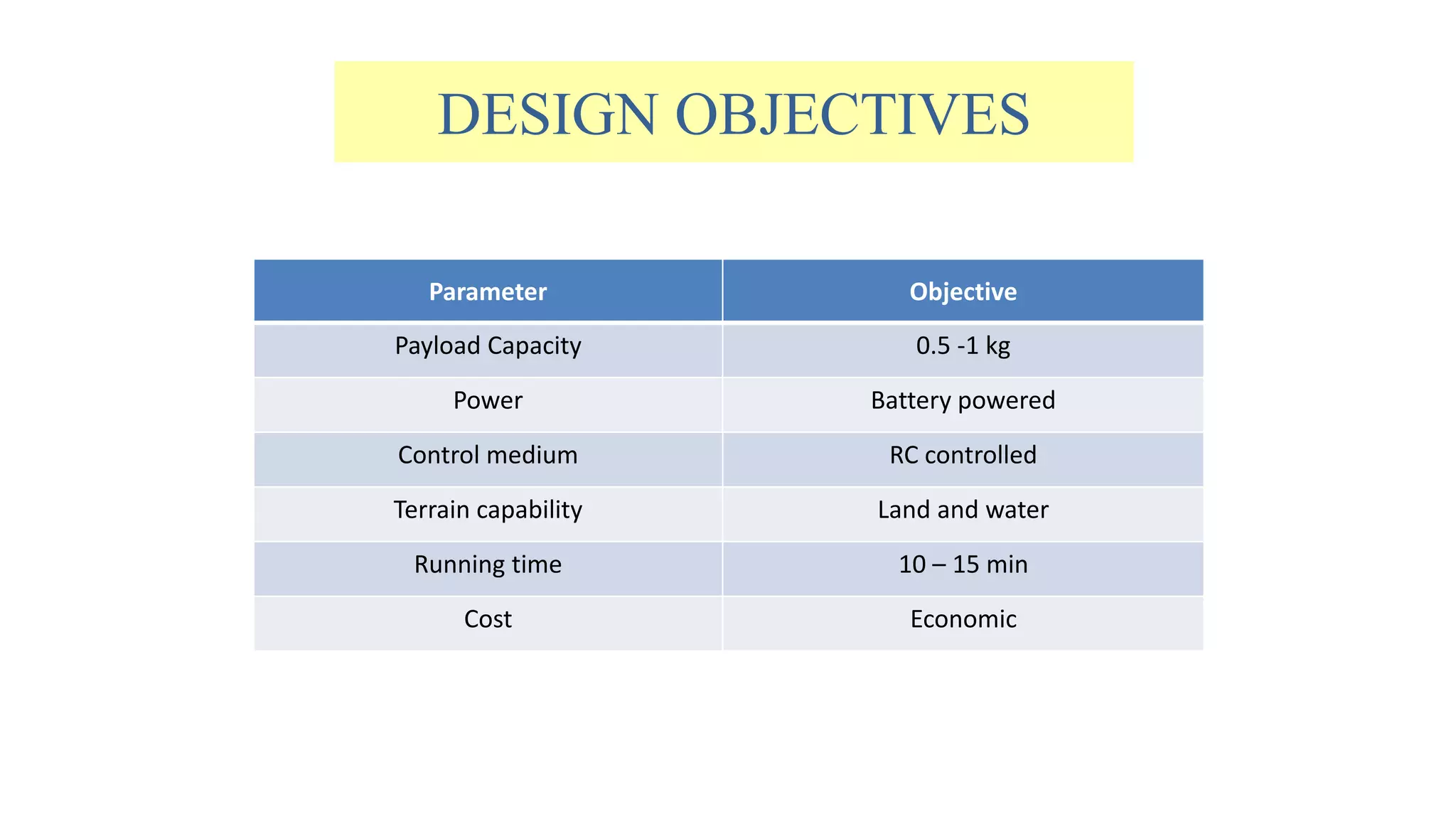

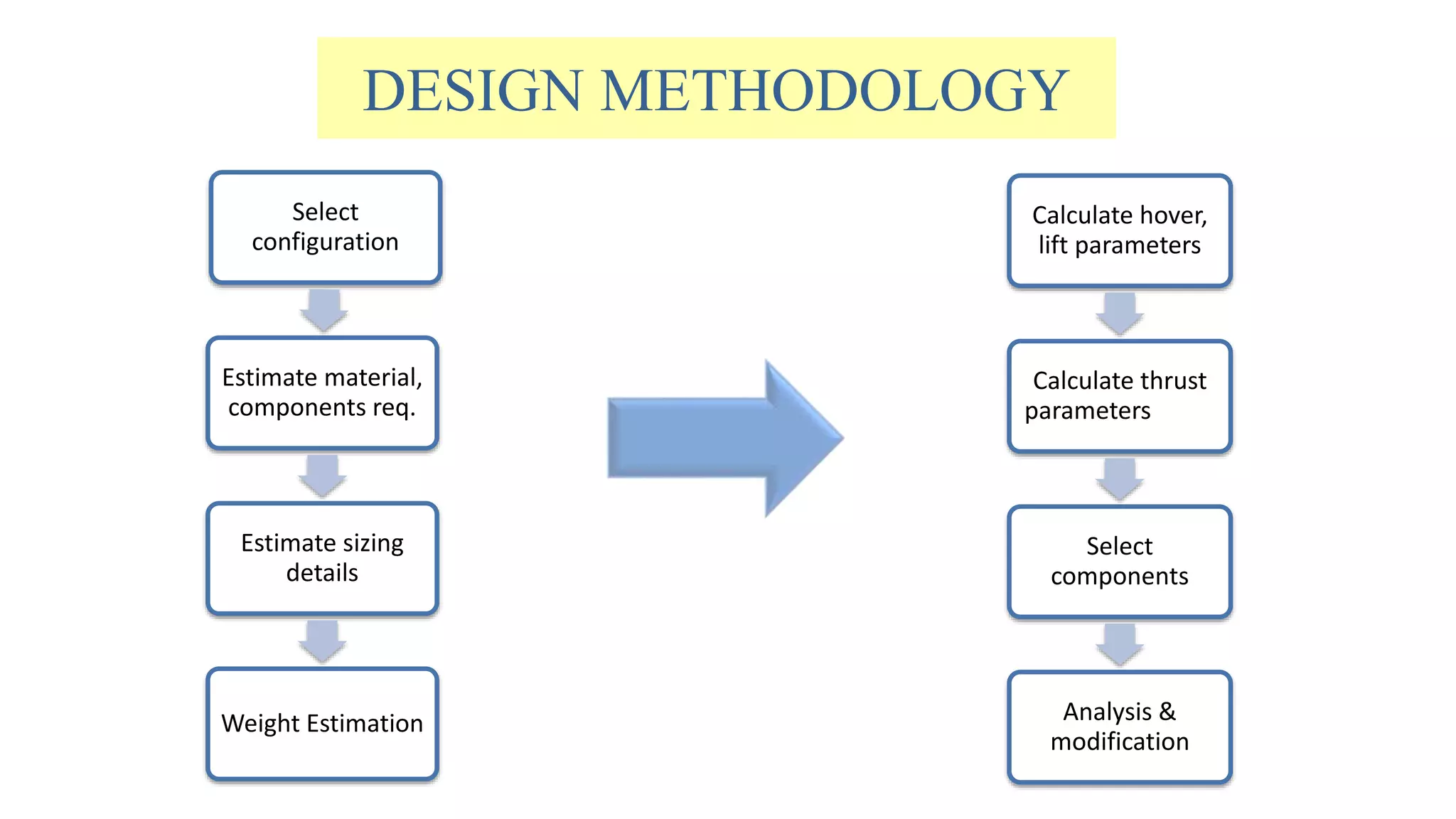

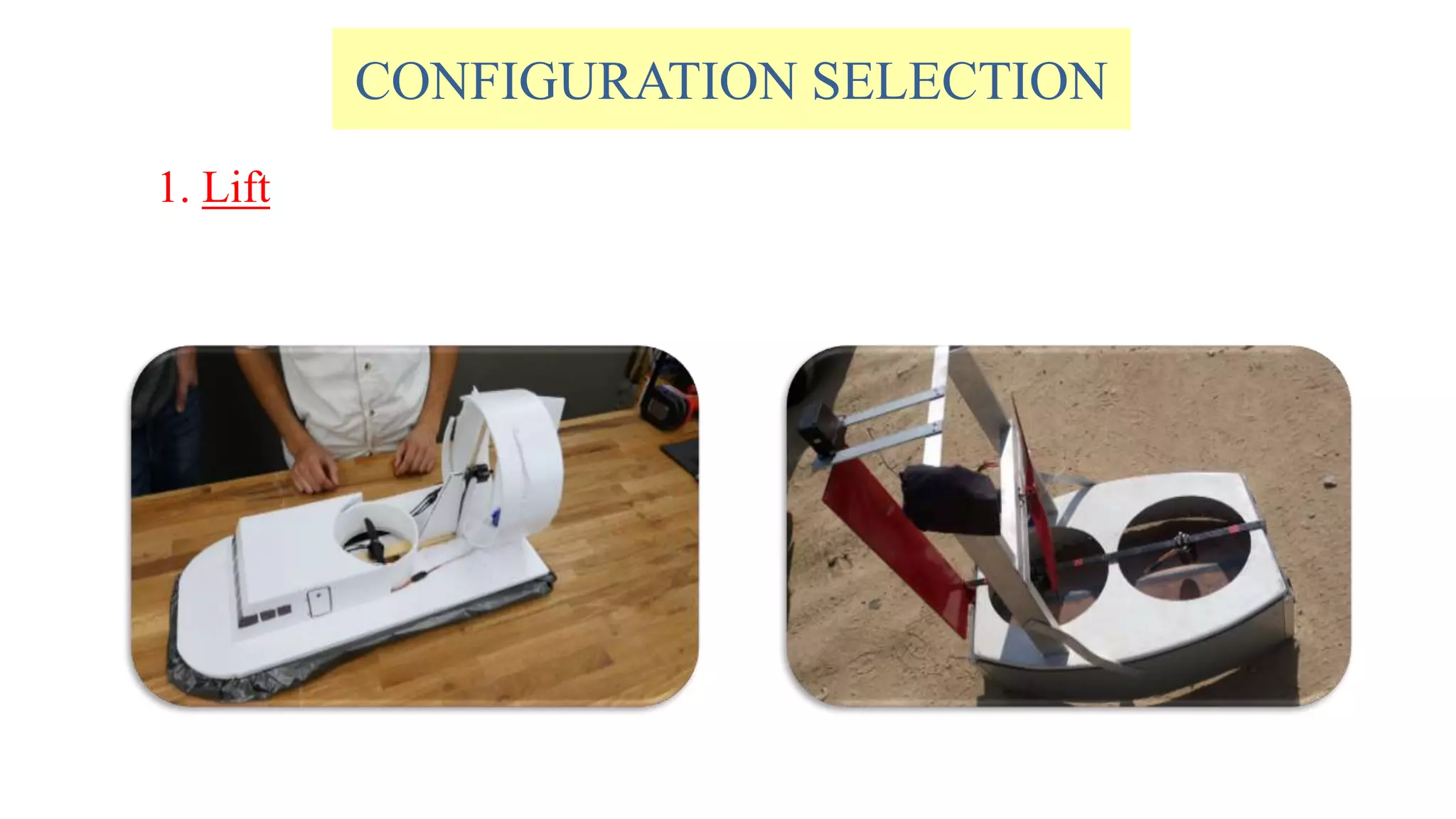

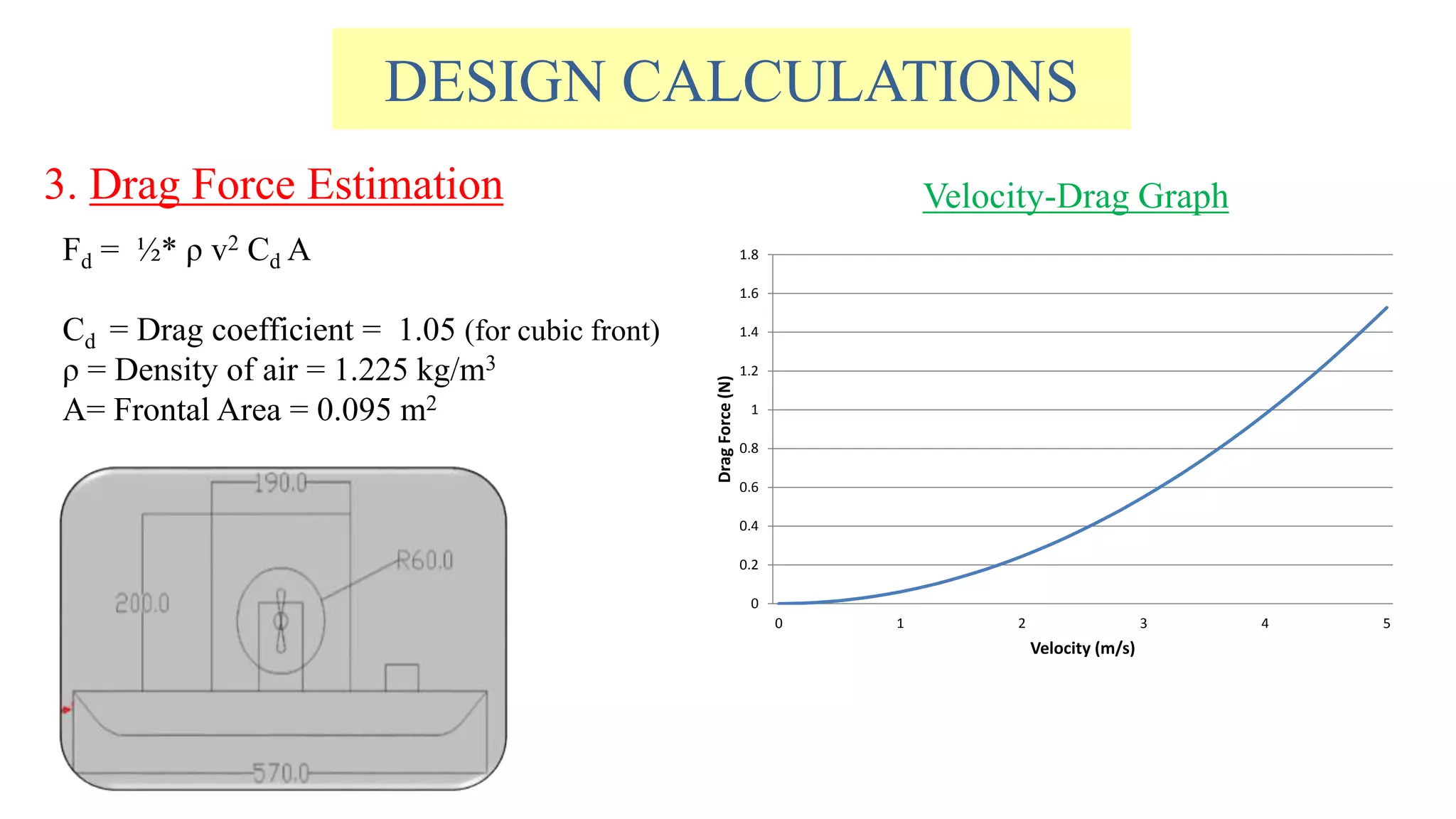

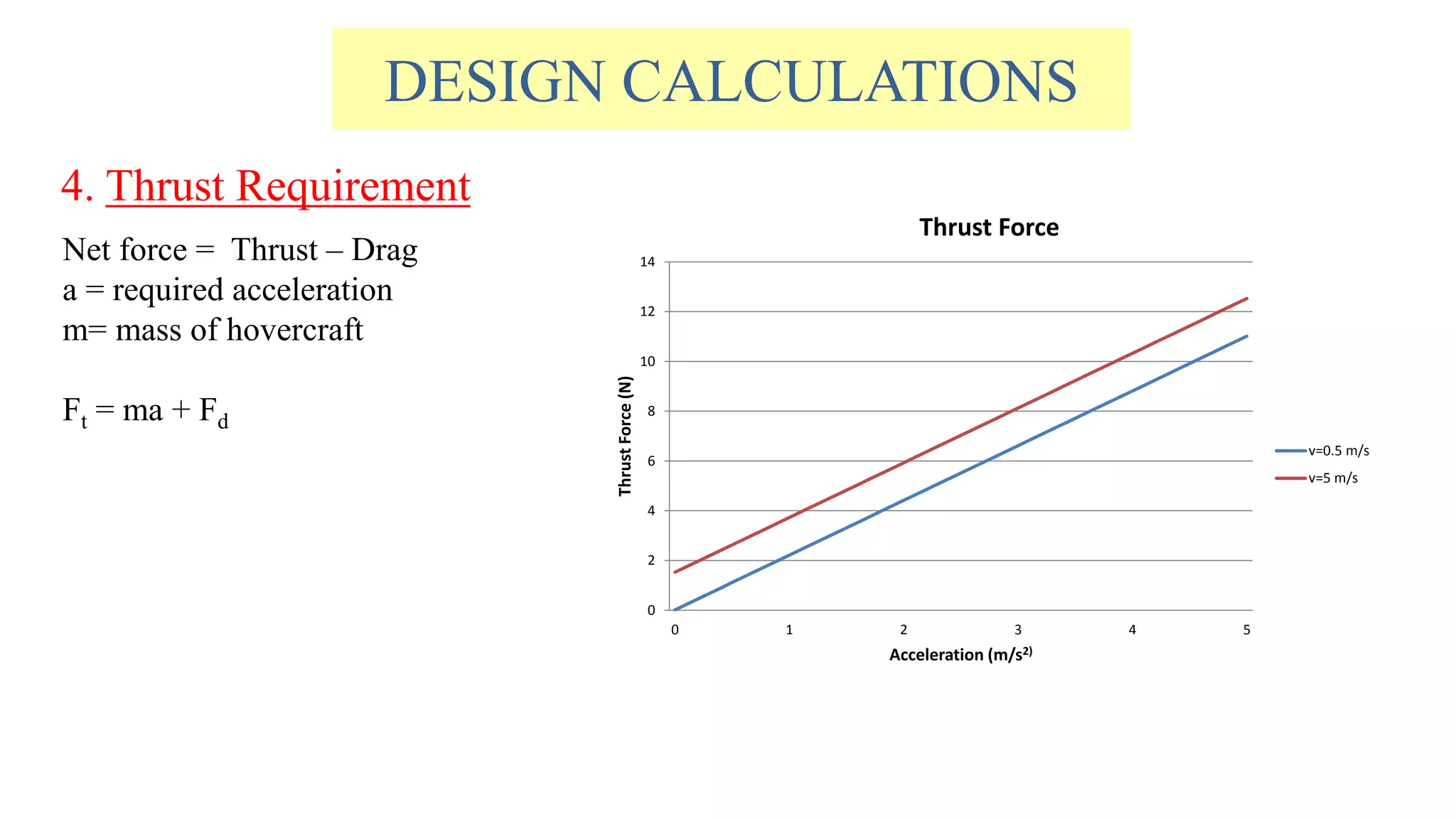

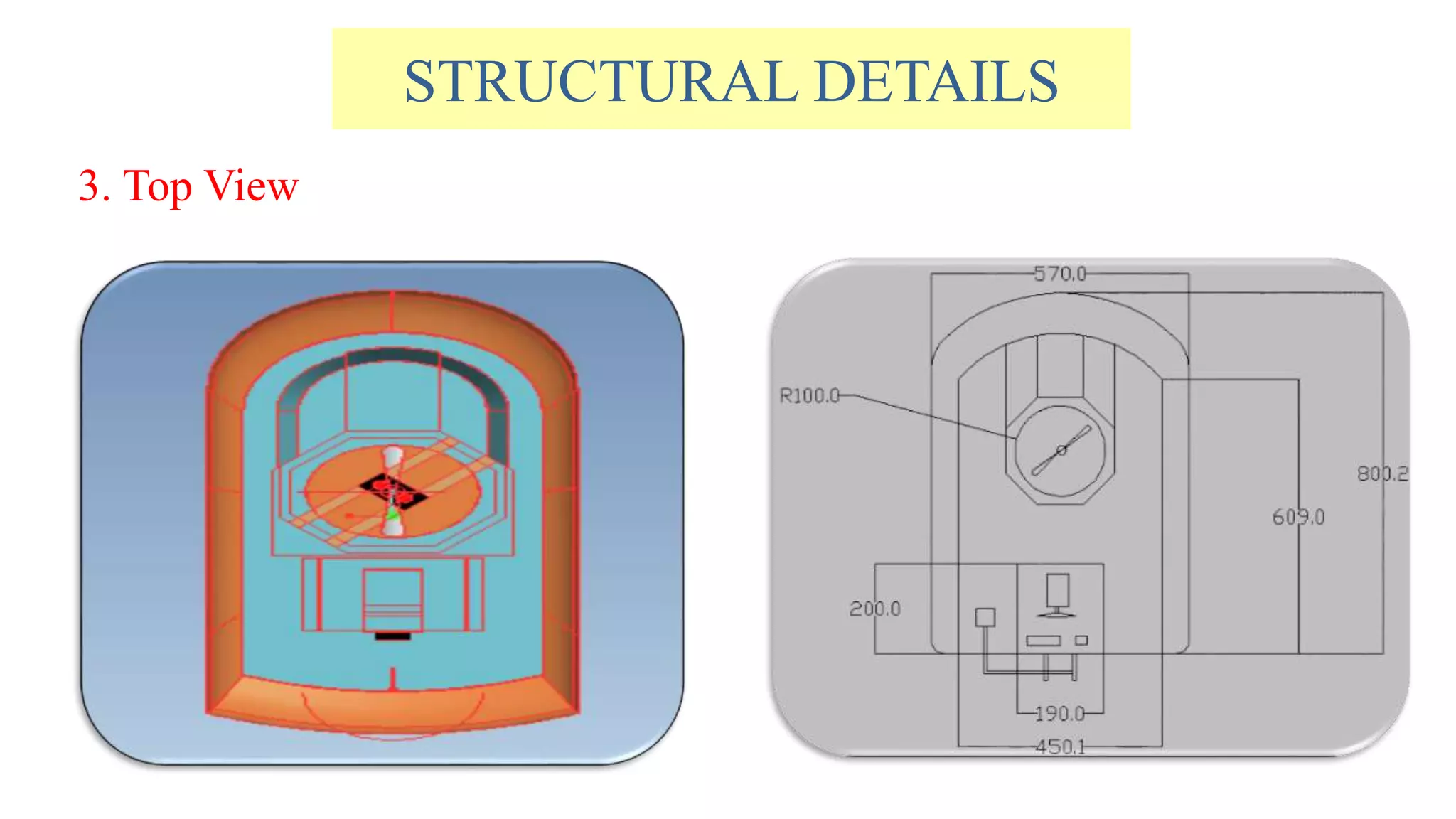

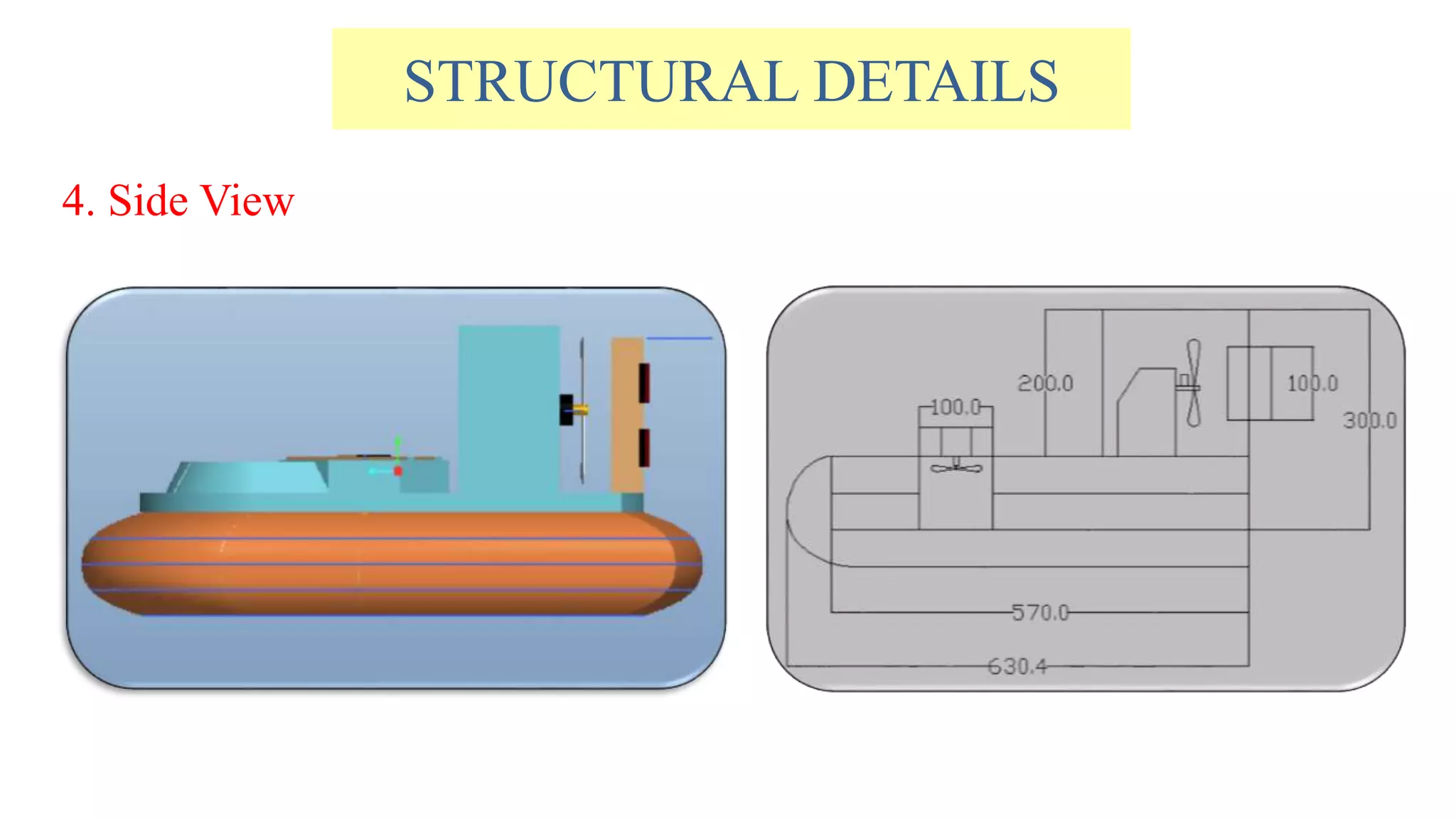

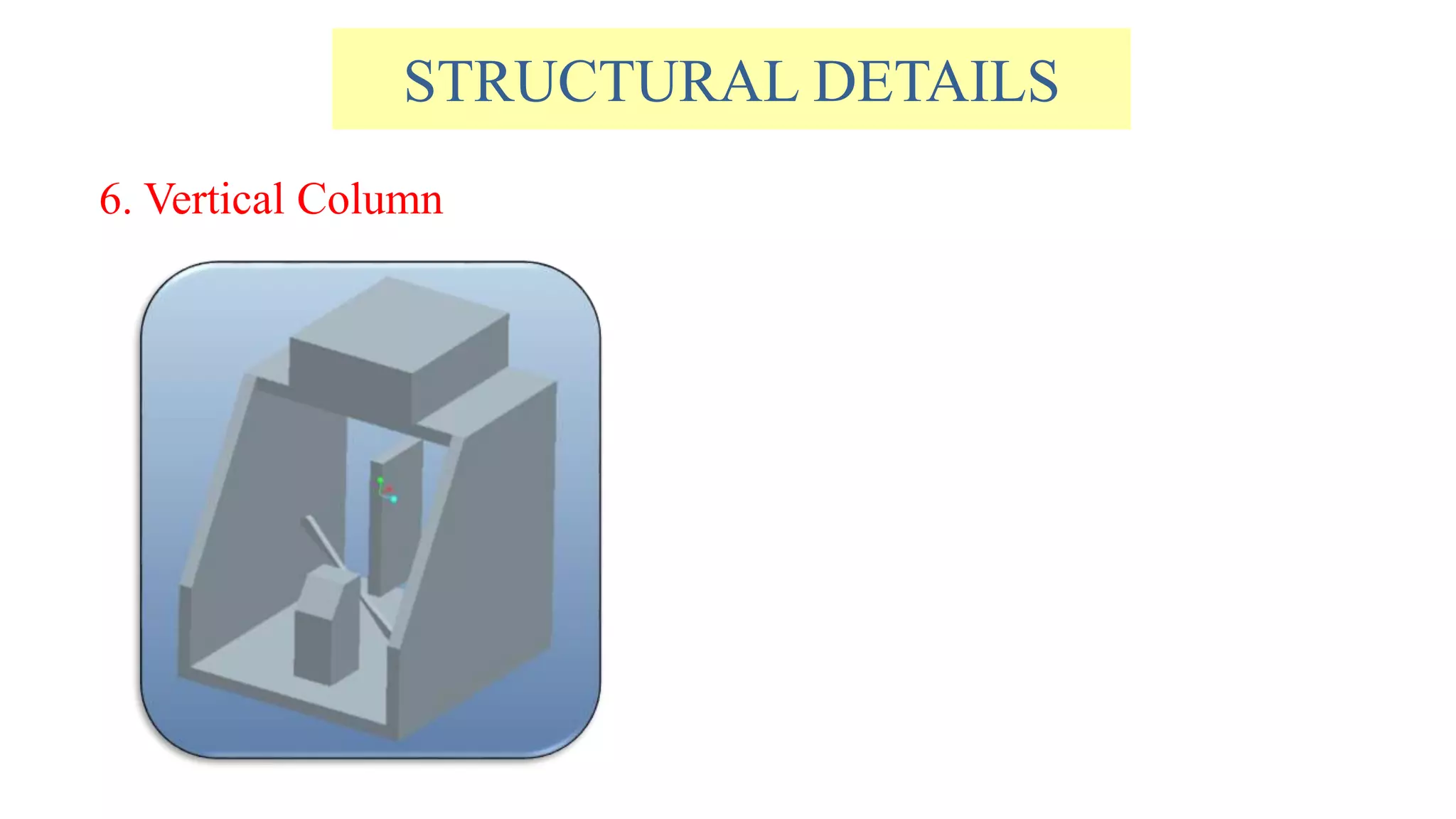

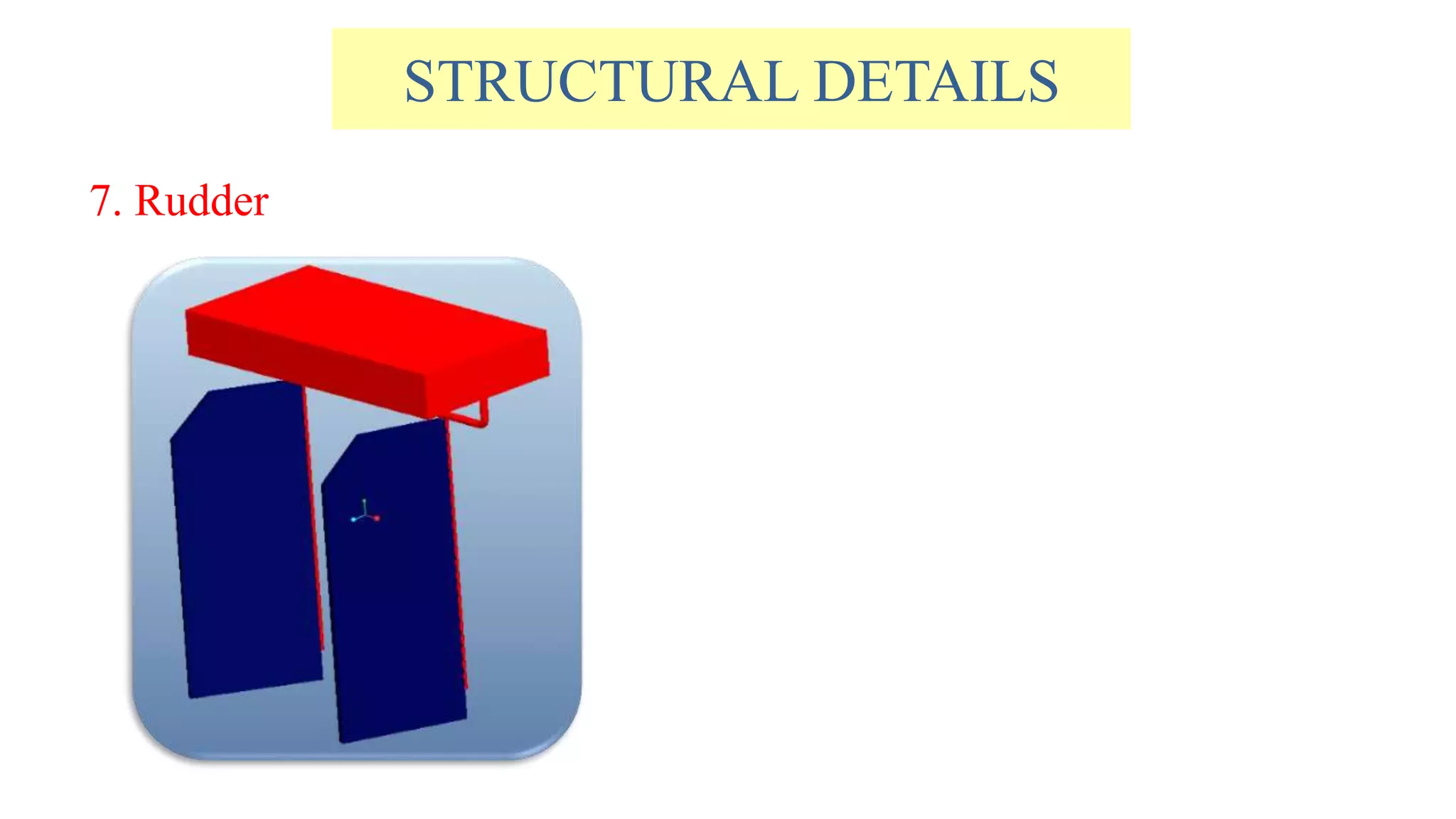

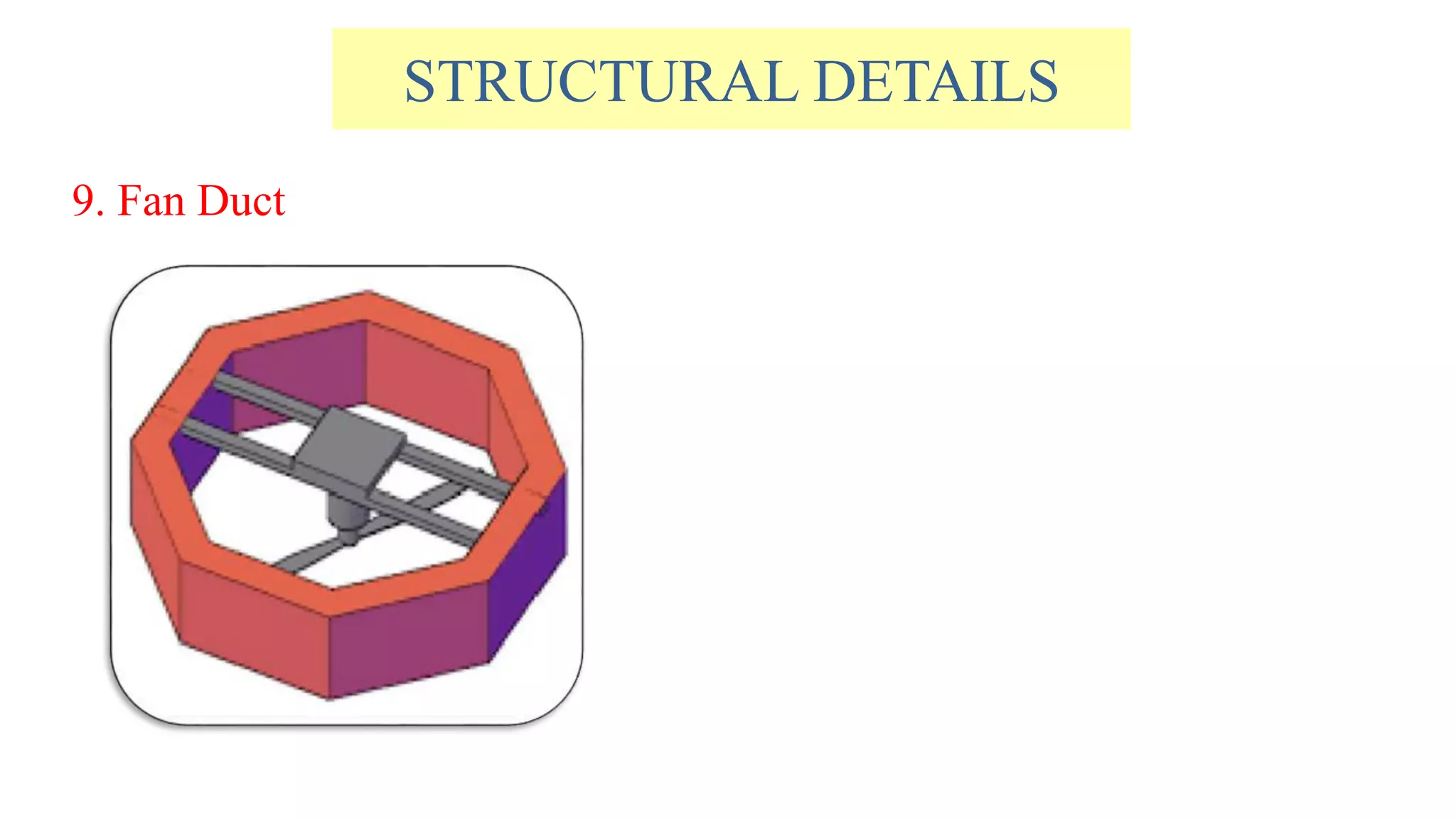

- Descriptions of the working principles, basic parts, design considerations and calculations, structural details, and applications of hovercraft.