Low pressure over molding Supplier

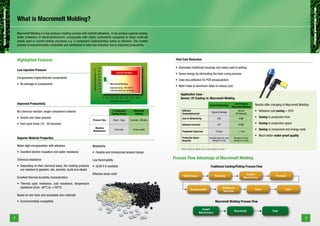

- 1. 2 3 Mold Case Encapsulate Insert Electronics Overmold Test Cure Setting or Vacuum Test Palletize Insert Electronics Preheat What is Macromelt Molding? Macromelt Molding is a low pressure molding process with hotmelt adhesives. It can achieve superior sealing, better protection of electrical/electronic components with higher productivity compared to those materials widely used in current sealing processes e.g. 2-component casting/potting resins or silicones. This notable process is environmentally compatible and contributes to total cost reduction due to improved productivity. Process Flow Advantage of Macromelt Molding Traditional Casting/Potting Process Flow Macromelt Molding Process Flow Low Injection Pressure Encapsulates fragile/delicate components • No damage to components Improved Productivity No chemical reaction: single-component material • Simple and clean process • Fast cycle times (10 - 50 seconds) Superior Material Properties Water-tight encapsulation with adhesion • Excellent electric insulation and water resistance Chemical resistance • Depending on their chemical basis, the molding products are resistant to gasoline, oils, alcohols, acids and alkalis Excellent thermal durability characteristics • Thermal cycle resistance, cold resistance, temperature resistance (from -40°C to +150°C) Based on non-toxic and renewable raw materials • Environmentally compatible Application Case - Sensor: 2C Casting vs. Macromelt Molding Current Technology Low Pressure Macromelt Molding Adhesive Consumption/unit 16g/unit (Casting) 4g/unit (PA Hotmelt) Cost of Adhesive/kg € X € 2X Adhesive Cost/unit € Y € Y/2 Production Cycle/unit 2 hours 1 min Production Space Required Occupies space for case storage curing No space for case storage nor curing Results after changing to Macromelt Molding: • Adhesive cost saving = 50% • Saving in production time • Saving in production space • Saving in component and energy costs • Much better water-proof quality Highlighted Features Moldability • Flexible and miniaturized product design Low flammability • UL94 V-0 available Effective strain relief 400 350 300 250 200 150 100 50 0 0 200 400 600 800 1000 1200 1400 2-Component Casting Resins Macromelt Molding Process Time Hours - Days Seconds - Minutes Machine Maintenance Every day Once a week Total Cost Reduction • Eliminates traditional housings and cases used in potting. • Saves energy by eliminating the heat curing process. • Uses less adhesive for PCB encapsulation. • Mold made of aluminum helps to reduce cost. Above data are taken from a real reference case WhatisMacromeltMolding? WhatisMacromeltMolding? Injection Molding Macromelt Molding Injection temp: 180-240°C Injection pressure: 5-40 bar Injection pressure (bar) Injectiontemperature(°C)

- 2. 4 5 Polyamide Polyolefin PAX Hotmelt Product Macromelt® OM Macromelt® Q Macromelt® OM730 Service Temp (°C) -40 to +150 -20 to +100 -20 to +150 inherently stable +200 Molding Temp (°C) +180 to +240 +180 to +200 +200 to +240 Viscosity range ( mPa.s ) 1,000 to 7,000 5,000 to 15,000 ca. 2,000 Shore Hardness A80 to D50 A60 to A90 D42 Adhesion Properties Superior adhesion to plastics e.g. ABS, PBT, PVC Superior adhesion to PP, PE, PET passes reflow process UL94 V-0 - - Macromelt Molding Applications Automotive Electronics Macromelt molding can be applied to various automotive electronic systems and devices, such as tire pressure monitoring systems (TPMS), PCBs for seat occupant sensors, belt lock sensors, ECUs for motorcycles, air quality sensors, antennas for RF devices, smart entry (E-Key) systems, etc. 1. Water-tight connector 2. Micro-switch 3. Absolute angle sensor 4. Intelligent battery sensor 5. Air quality sensor Connector potting Hotmelts are used for sealing the plug and also for cable strain relief. Grommet injection molded in place The molding process can be used to mold grommets in place.This eliminates the time-consuming process of slipping the grommet on, which can cause repetitive strain injury. The molding can also include strain relief, which also enhances its esthetics. Electronic component encapsulation It is the low pressure applied during the molding process that prevents damage to the sensitive electronic components and elements. The molding protects the electronics from external influences (moisture, mechanical stressing, etc.) and is capable of serving as a housing. Types of Macromelt Molding Materials Three Main Application Groups of Macromelt Molding Products MacromeltMoldingApplications WhatisMacromeltMolding? What is Macromelt Molding? 6. Temperature sensor

- 3. 6 7 8. Antenna coil 9. GND terminal Mobile phone battery Grommets / Sockets Molded connectors / Sensors with water-tightness strain relief Mobile Phone Applications Macromelt molding can be applied to the mobile phone battery, antenna, strobe flash, and other delicate components that require water-tightness, protection or encapsulation. Automotive Electronics MacromeltMoldingApplications MacromeltMoldingApplications 7. Other kinds of sensors Macromelt Molding Applications PCB Overmolding

- 4. 8 9 Molding Machine Mold Set The molding system consists of the molding product, the mold set, the machine, and the melting unit. The melting unit for the hotmelt is usually used for injection of the hotmelt adhesive into the mold set at lower pressure compared to conventional injection molding machines. The mold set, which is usually made from aluminum, facilitates the process to trial stage as it is lower in cost compared to conventional ones. Mold Set Aluminum can be used as the material for making the mold set for Macromelt Molding due to • Lower injection pressure of the process • Better thermal conductivity of aluminum • No abrasive ingredients, e.g. fillers, glass fibers, contained in hotmelt Steel can also be used as the material for the mold set. If the component to be over-molded has steel or hard glass filled components, it is recommended to have steel inserts in this area of the cavity. Molding Machines There are many types of molding machines available: • For small-scale production with manually opened mold set. • For production that needs higher productivity and output, with a sliding stage or rotary table for the mold set. Further details about molding machines are available from our machine partners in each country. System Solution Henkel supports customers throughout project development, from initial sample-making with a trial mold set to consultancy on designing complete packages for mass production based on long experience with this low pressure molding technology. MoldingMachineMoldSet MoldingMachineMoldSet Hotmelt Adhesives Technical Support Supply Molding Product Supply System Supply Melting Unit Molding Machines Mold Sets Melting Unit Supplier Customer Select right hotmelt • Check requirements • Spot test, if required • Develop new product • Trial with mold set • Produce molded samples for evaluation • Environmental resistance • Chemical resistance • etc. • Check requirements • Decide right specifi- cation • Supply hotmelt and machines • Start production Prototyping Evaluation by customer Prepare for production Project completion

- 5. 10 11 Casting Resins 1. Antenna coil 2. Connector and micro switch 3. Transformers Casting Applications: Henkel also offers casting resins based on epoxy and polyurethane. Their properties can be adjusted in many ways by modifying their chemical compositions. They can be engineered to be very hard and impact-resistant or soft and elastic. With low processing viscosity, they can fill even the smallest gaps. Technical Information Casting Resins General Overview Product CR 8101 CR 3127 CR 3311 CR 5441 CR 6127 Hardener UK 5400 CR 4300 UK 5600 CR 4300 CR 4300 Mixing ratio (weight) 4:1 5:1 100:25 100:45 85:15 Properties Color Light brown Light brown Colorless Light brown white black Viscosity at 20°C mixed (mPa.s) 2650 3400 3200 1000 2400 Potlife at 20°C (min) 60 90 30 25 2-15-90 Shore hardness D 35 - 45 D 60 - 70 000 40 D 50 - 60 A 84 Flammability UL94 - V-0 - - V-0 for Electronic Electrical Applications Technical Information Product Range for Macromelt Molding Polyamide General Overview Product Test Method OM652 OM657 6208 6208S OM633 OM638 OM641 OM646 OM673 OM678 OM648 OM730 Properties Color - Amber Black Amber Black Amber Black Amber Black Amber Black Black Amber Service Temp Range (°C) - -40 to +100 -40 to +100 -40 to +130 -40 to +130 -40 to +140 -40 to +130 -20 to +150 Softening Point (°C) ASTM E28 +155 +155 +175 +175 +185 +175 +200 after curing Viscosity at +210°C (mPa.s) ASTM D3236 4,000 3,000 3,500 7,000 3,000 7,300 ca. 2,000 Shore Hardness ISO 868/15s A77 A82 A90 A92 A90 A93 D42 Creep Resistance (°C) Henkel Method MH11 +125 +130 +155 +155 +130 +155 +200 Cold Flexibility (°C) ASTM D3111 -50 -40 -30 -35 -40 -30 -15 Flammability UL94 File E182771 V-0 V-0 V-0 V-0 V-0 - - Low temp. storage (°C) Henkel Method MH40 -40 1000h Special Properties Good cold flexibility RTI value for 6208S: 95°C UV stabilized Moisture curable Adhesion Properties Substrate PA6.6 Good Good Moderate Moderate Moderate Moderate Moderate PVC Good Good Good Excellent Good Moderate Good ABS Good Good Moderate Moderate Moderate Moderate Moderate Macromelt products are thermoplastic hotmelt adhesives based on natural fatty acids. They show good adhesion to plastics like PA 6.6,ABS and PVC, low temperature flexibility, a wide service temperature range, and superior molding properties. CastingResins The data above is based on our knowledge and experience. Due to different materials and conditions of application which are beyond our knowledge and control we strongly recommend carrying out sufficient tests and consulting of our technical customer service. Except for willful acts any liability based on such recommendations or any oral advice is hereby expressly excluded. A variety of adhesive values – spot tests, peel strength, shear strength – are available on request or can be supplied after testing by our technical customer service team. Electrical Properties: Volume Resistivity DIN IEC 60093 ~ 1012 Ω cm Dielectric Strength DIN IEC 60243-1 ~ 20 kV/mm The electrical values of OM648 and OM720 are not available. TechnicalInformation The data above is based on our knowledge and experience. Due to different materials and conditions of application which are beyond our knowledge and control we strongly recommend carrying out sufficient tests and consulting of our technical customer service. Except for willful acts any liability based on such recommendations or any oral advice is hereby expressly excluded.

- 6. QL-CUSTOM TECHNOLOGY LTD Your Low Pressure Molding Supplier https://www.ql-custom.com/lpm.html Cable assembly and Wire Harness https://www.ql-custom.com/cableassy.html