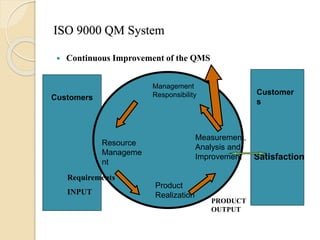

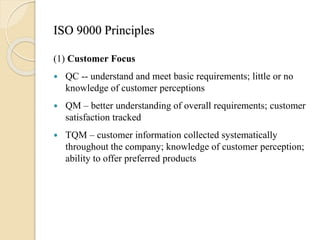

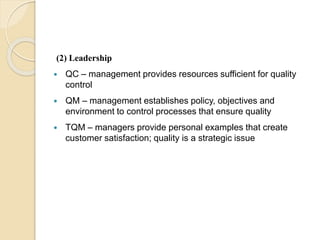

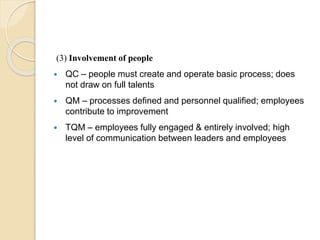

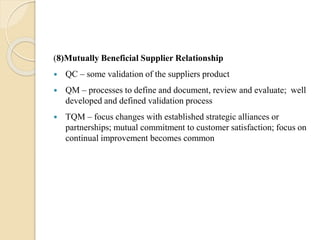

The document provides information on quality management systems (QMS). It defines a QMS as a system for managing quality in an organization that includes products, processes, operations, and customer satisfaction. A key aspect of a QMS is the process approach to management, with an emphasis on continual improvement. The document also outlines the main elements of a QMS based on ISO 9000 standards, including management responsibility, resource management, product realization, and measurement, analysis and improvement.