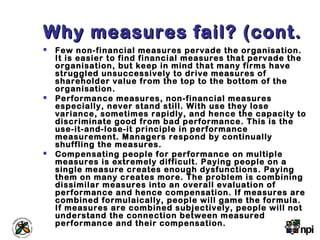

This document discusses performance measurement for companies participating in a Workplace Challenge Program. It addresses:

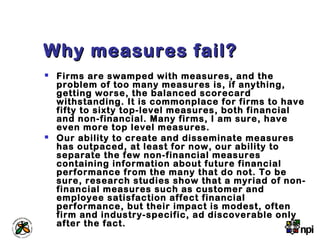

- The lack of uniform performance measures makes it difficult to determine overall competitiveness and productivity improvements.

- The objective is to identify uniform measurement variables in quality, speed, cost and morale that reliably indicate performance improvements.

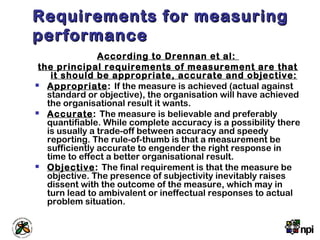

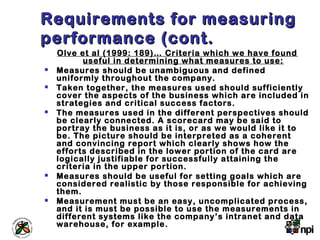

- It defines productivity and performance, discusses why measures fail and requirements for effective measurement, including being appropriate, accurate and objective.

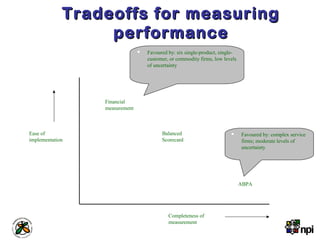

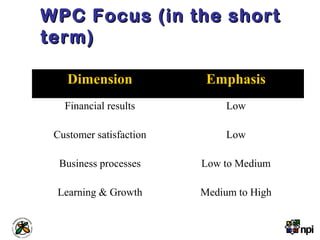

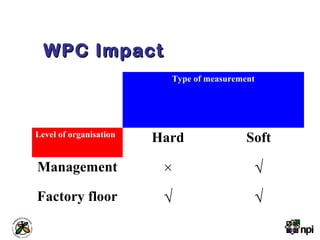

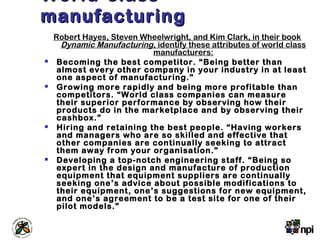

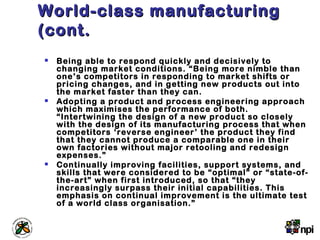

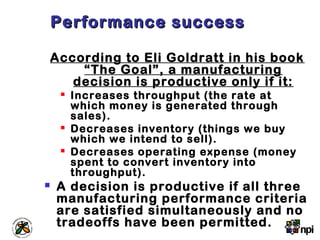

- It also discusses world-class manufacturing attributes, how to measure performance success, and tradeoffs between different measurement approaches.

![How to measure?How to measure?

George Sadler (1993: 3-3.1)[1]…for

productivity measurement, physical

measures, properly weighted

remain significantly more accurate

than dollar-value measures (even

when adjusted or “real”) can ever

be. Purely value-based productivity

measures can be useful, but in the

basic simplified plant-level

productivity measurement

approaches, physical measures

predominate.

[1] William Christopher et al, eds.](https://image.slidesharecdn.com/a5fbab2d-1b54-4e62-933c-a81168e0f35c-151106141447-lva1-app6891/85/QSCM-Perf-Mngt-Study-update-2004-14-320.jpg)