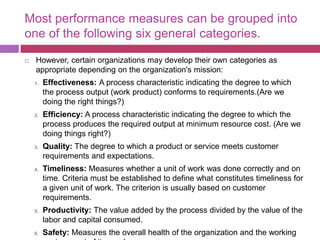

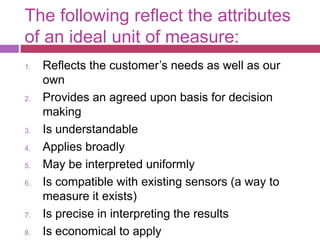

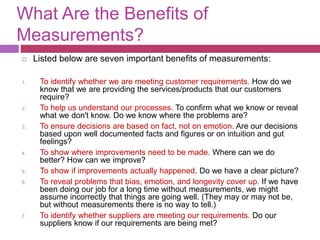

This document discusses quality performance measurement techniques. It defines performance measurement and explains that it is an important part of Total Quality Management programs. Performance measures help managers know when and where to implement changes by providing appropriate information. The document outlines some challenges with traditional performance measurement systems and recommends developing new measures that align with TQM principles like customer focus, continuous improvement, and cross-functional teamwork. It also discusses characteristics of effective performance measurement systems and categories of performance measures. Overall, the document emphasizes that performance measurement provides valuable information for understanding processes, making decisions, and driving improvements.