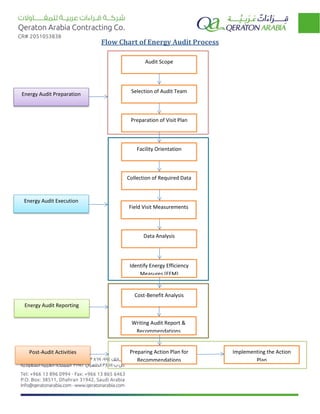

Qeraton Arabia provides energy auditing services to help clients lower energy costs and protect the environment. They conduct in-depth audits that include analyzing historical energy use, on-site measurements, identifying potential efficiency solutions, engineering and economic analysis of modifications, and reporting. The audits assess various equipment and utilities, using tools like power loggers, thermography, and ultrasound scanning. The audit team includes energy auditors and technicians. The final deliverables are a presentation of findings and recommendations, and a comprehensive report with technical inventory, consumption analysis, efficiency measures, and financial analysis.