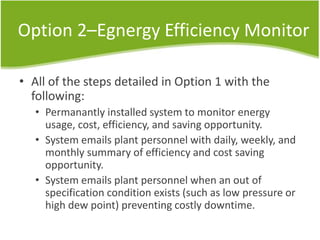

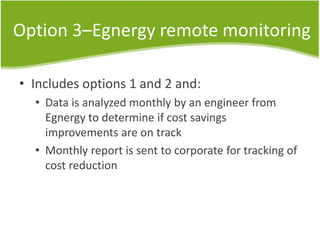

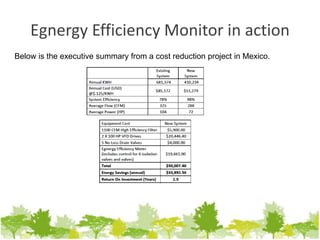

This document discusses three options for industrial energy efficiency services from Egnergy. Option 1 involves an audit of a plant's current energy systems to assess costs, efficiencies, and savings opportunities. Option 2 adds permanent monitoring equipment. Option 3 includes options 1 and 2 plus remote monitoring by Egnergy engineers. The monitoring system would alert staff to issues and Egnergy would provide monthly reports tracking cost reductions. An example is given of potential savings from optimizing a compressed air system. Egnergy also offers various compressed air and nitrogen monitoring and control products.