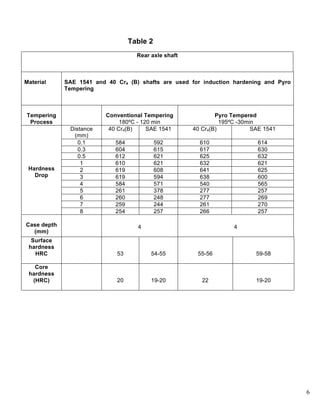

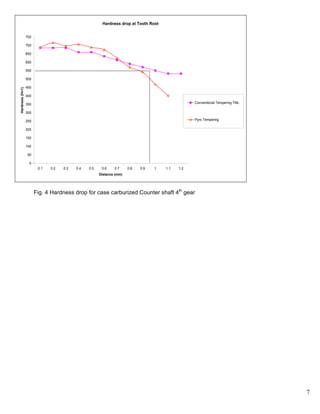

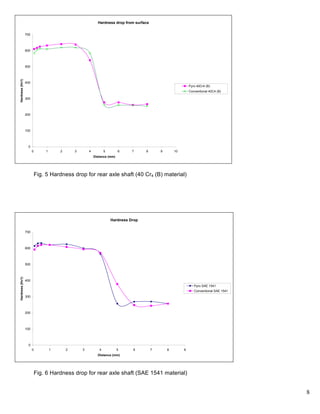

1. The document compares conventional tempering processes to high speed tempering using pyrolysis ovens. Trials were conducted on gears and rear axle shafts to demonstrate the benefits of high speed tempering.

2. The trials showed that high speed tempering significantly reduced tempering cycle times from 90 minutes to 40 minutes for gears and from 120 minutes to 30 minutes for induction hardened shafts. This reduction in cycle time leads to lower costs, reduced fuel consumption and carbon footprint.

3. Hardness tests also demonstrated that high speed tempering achieved equivalent hardness profiles and mechanical properties compared to conventional tempering, despite the much shorter cycle times.