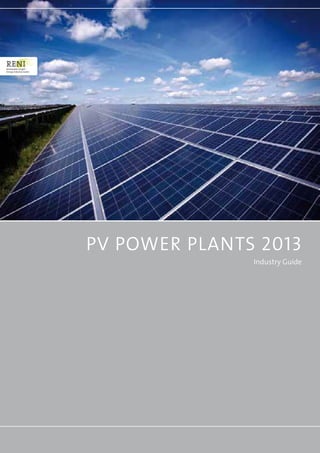

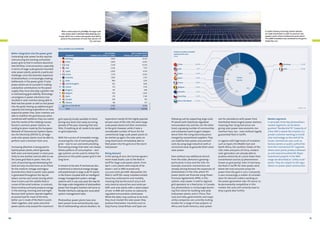

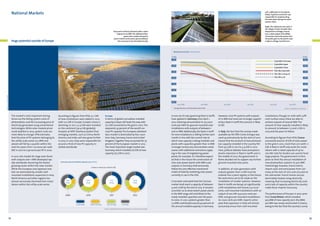

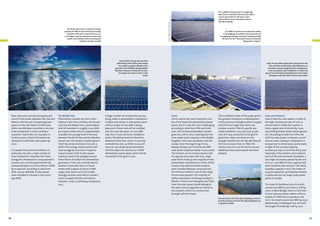

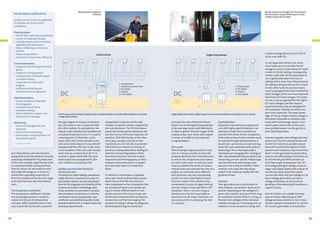

The document discusses the growing size and scale of photovoltaic power plants. Large-scale PV plants are now reaching dimensions similar to conventional power plants, with some solar parks exceeding 100 MW in capacity. The world's largest solar power plant under construction in 2015 will have a 579 MW capacity. PV outputs are achieving scales equal to coal power stations, and some propose PV plants exceeding 1 GW in Asia. Large-scale PV plants are becoming an important long-term investment with relatively low risk due to stable electricity generation costs and revenue from government incentives.