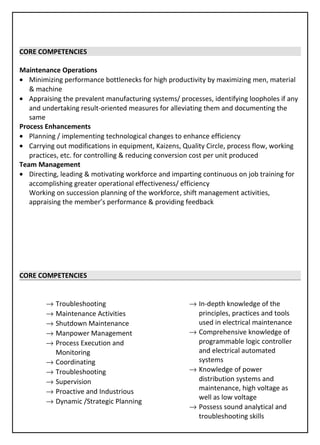

This document is a curriculum vitae for Purushothaman M. It summarizes his objective of finding a challenging job that utilizes his skills, his 5 years of experience in maintenance operations and process improvements as a Maintenance Engineer, and his education which includes a diploma in electronics and communication engineering. It also lists his core competencies such as maintenance operations, process enhancements, and team management. Finally, it details his work experience at Ford India and RPP Windtech Services in maintenance and engineering roles.

![EDUCATION

→ Diploma in Electronics and Communication Engineering from Sri venkadesvara

polytechnic Collage, Cheyyar (TN) in 2007.

→ SSLC From KNNC Government School Munugapet (TN) in 2002.

WORK EXPERIENCE

Company Name : Ford India Pvt Ltd,

Designation : Maintenance Engineer [Body Shop]

Duration : September 2013 to Till Date.

Job Profile:

Key Result Areas

→ Accountable for :

o Executing FTPM activities in machines

o Carrying out Breakdown Maintenance of equipment’s

→ Trouble shooting in electrical and electronic circuits, power and control

schemes.

→ Handling of Motors, Transformers, Induction motors, PLC panel.

→ Preventive maintenances, Annual maintenances, Breakdown maintenances

are carryout ,

→ TPM & 5S & MTTR, MTBF, OEE Calculation of m/cs.

→ Shutdown maintenance in hazardous area,

→ Trouble shooting of PLC based Pneumatic control system,

→ Electrical PLC control system and mechanical maintenance of Conveyors,

→ Aliment setting for all conveyors.

→ TEM Preparation for monthly work orders

→ MOS – Maintenance Operating System

→ Involved in planned & breakdown maintenance work and achieve the targets

by maintenance techniques and spares planning.

→ Drafting the monthly / yearly/weekly action plan

→ Planning & implementation of preventive maintenance, & periodic

maintenance and achieving the targets effectively.](https://image.slidesharecdn.com/9b16a7d5-14f1-464c-9dc2-b9f02de26c6d-150503043128-conversion-gate01/85/PURUSHOTHAMAN-M_-_RESUME-3-320.jpg)