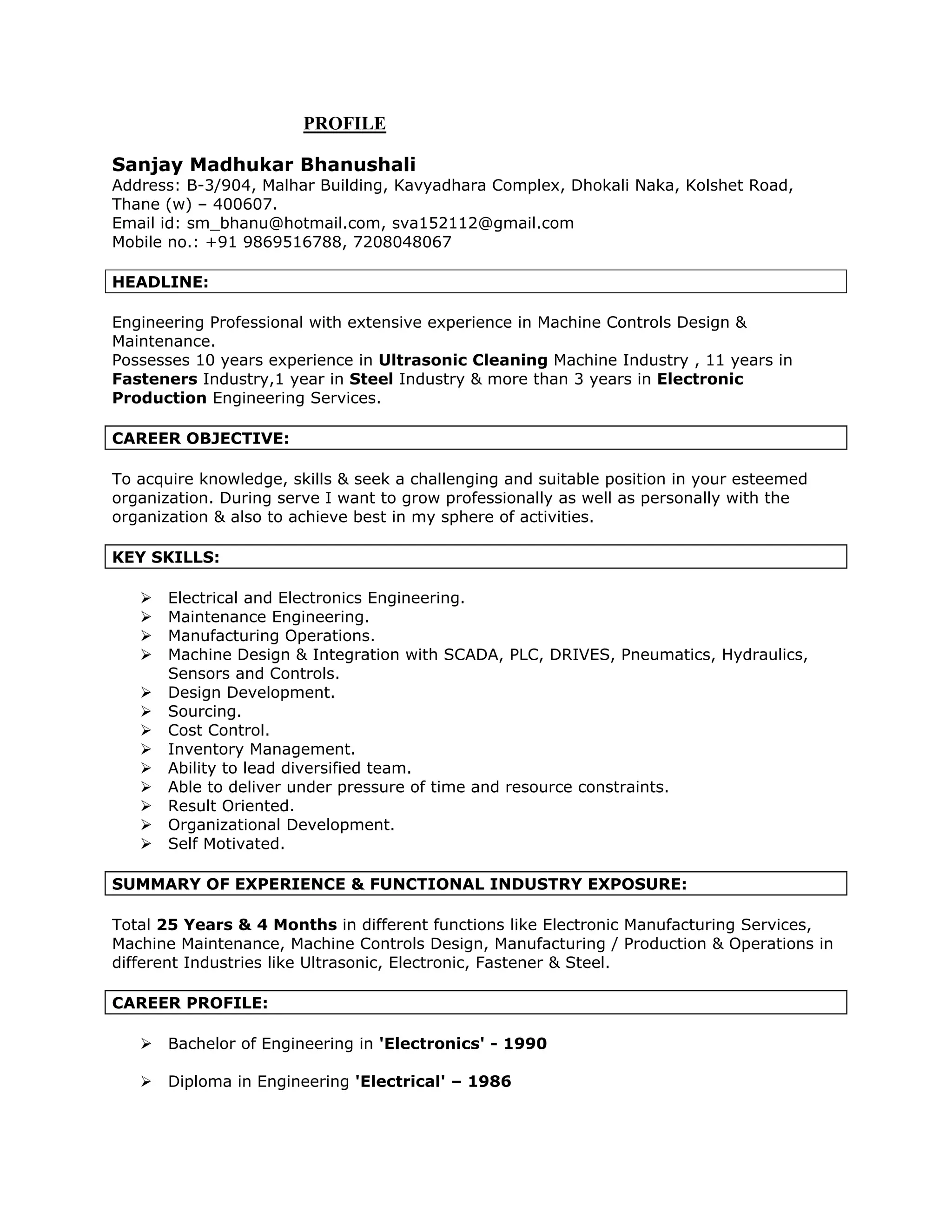

Sanjay Madhukar Bhanushali is an engineering professional with over 25 years of experience in machine controls design, maintenance, and manufacturing operations in industries like ultrasonics, electronics, fasteners, and steel. He currently works as the Works Manager at Vibronics Pvt. Ltd., an ISO 9001-2008 certified company, where he leads a team of 50 people and oversees operations. Previously, he worked as a Senior Maintenance Engineer at Precision Fasteners Ltd. for over 10 years and as a Trainee Maintenance Engineer at Special Steels Ltd. for 1 year.