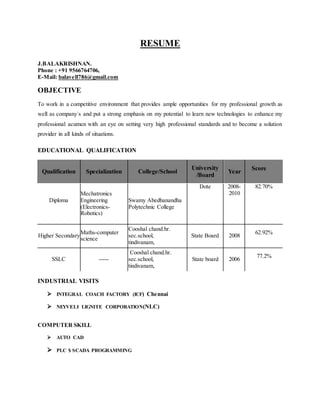

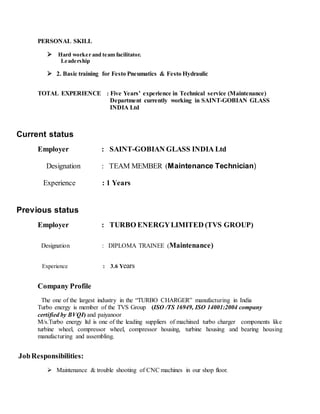

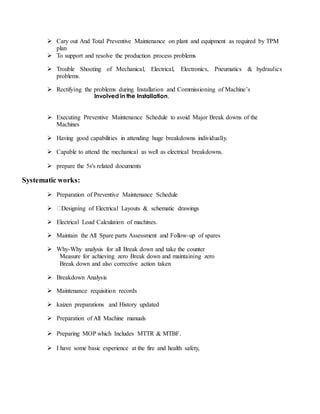

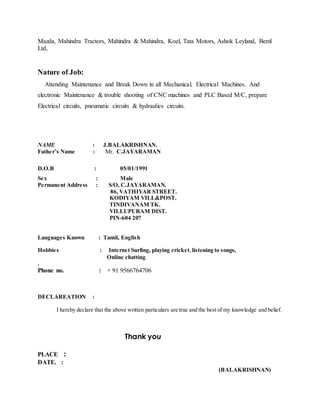

J. Balakrishnan is seeking a position that allows professional growth and learning of new technologies. He has a diploma in Mechatronics Engineering and experience in maintenance roles. His most recent role was as a maintenance technician at Saint-Gobian Glass India Ltd for 1 year, and he previously spent 3.6 years as a diploma trainee in maintenance at Turbo Energy Limited. He has skills in AutoCAD, PLC and SCADA programming, and has experience maintaining various machines, generators, chillers and other equipment.