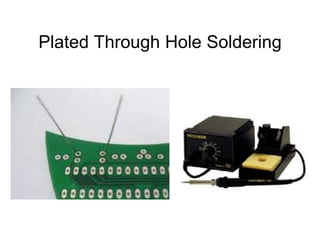

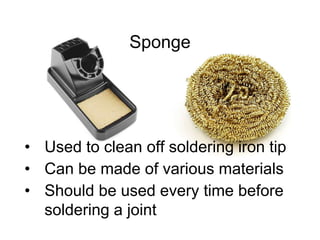

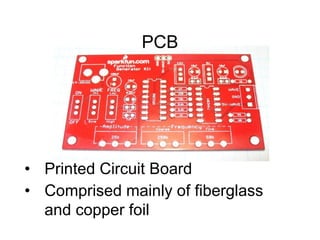

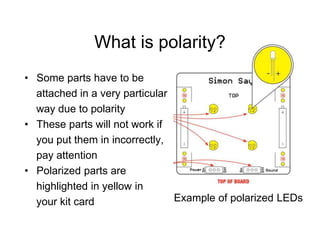

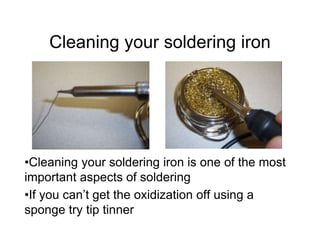

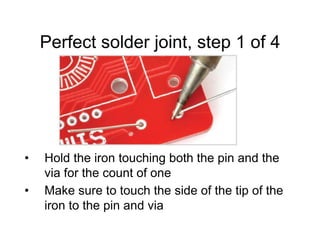

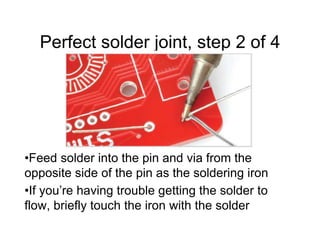

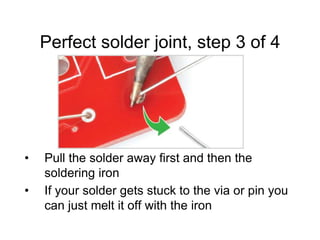

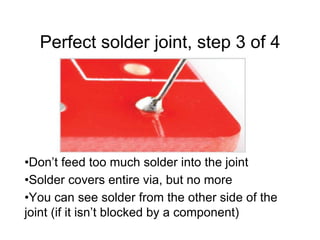

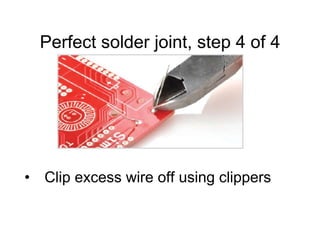

This document provides instructions and information about plated through hole soldering. It discusses the main tools used which include a soldering iron to melt solder, solder which is a metal glue to join parts and contains flux, and tweezers, clippers, and pliers to handle components. It also discusses best practices for soldering such as cleaning the soldering iron tip before each joint, applying flux, and creating a perfect joint by heating both parts simultaneously before feeding solder in. Safety practices like wearing goggles are also emphasized.