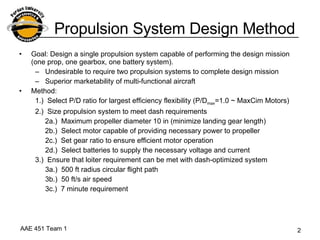

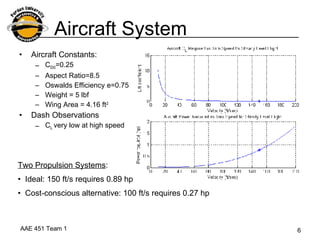

1) The document summarizes the design of a single propulsion system capable of performing the design mission requirements of dashing and loitering for an aircraft.

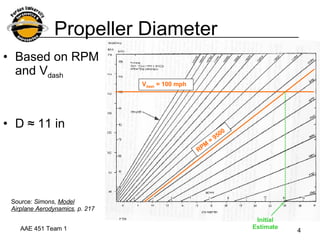

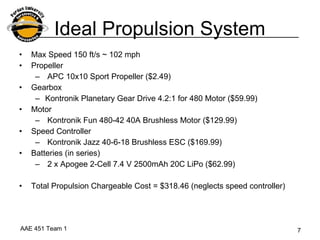

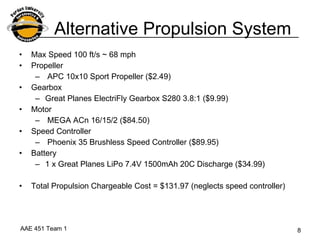

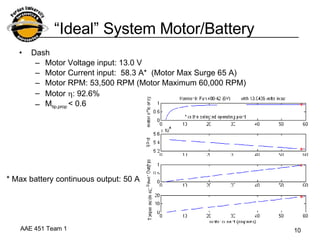

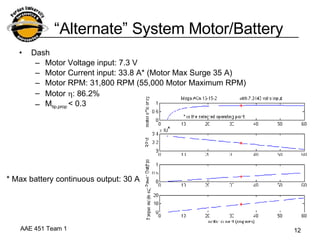

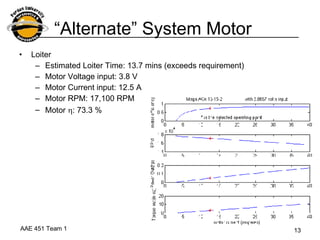

2) An "ideal" and higher performance system is designed that can dash at 150 ft/s but costs $318, while an "alternate" lower cost system capable of dashing at 100 ft/s is designed that costs $132.

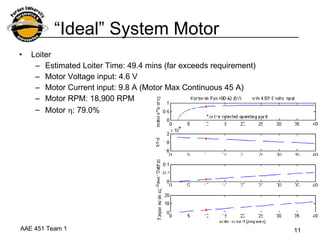

3) Both systems meet the loitering requirement of circling for 7 minutes, though the ideal system can loiter much longer at 49 minutes compared to 14 minutes for the alternate system.