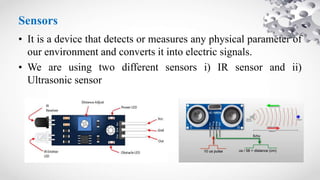

This document describes the design and development of a sensor controlled trolley. It begins with an introduction to trolleys and their use in industry. Site visits were conducted at two factories to observe problems with current manual trolleys. The main problems identified were cleaning of tracks, limited work space, and difficult loading/unloading. Design objectives were set to increase mobility and work space for workers. A literature review covered sensor-controlled carts and robots. Components of the proposed sensor-controlled trolley include sensors, a controller, motors, and a battery. Path tracking will be achieved using IR and ultrasonic sensors. An Arduino board will serve as the controller. The trolley structure will be made of I-channel material