This document summarizes the design of a 1000 KVA, 33KV/11KV power transformer. Key details include:

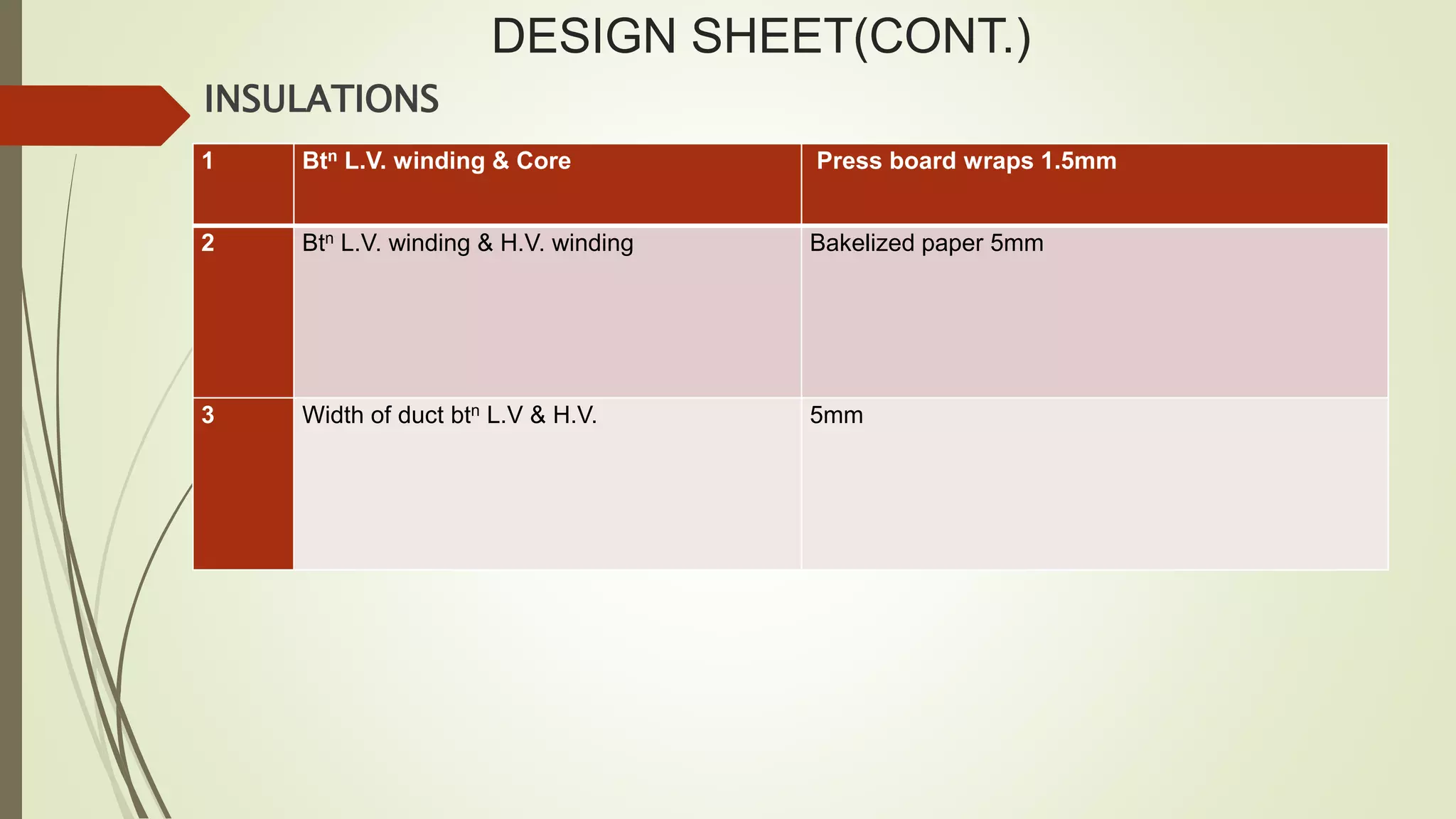

- Core and winding designs to meet specifications like voltage ratio and impedance

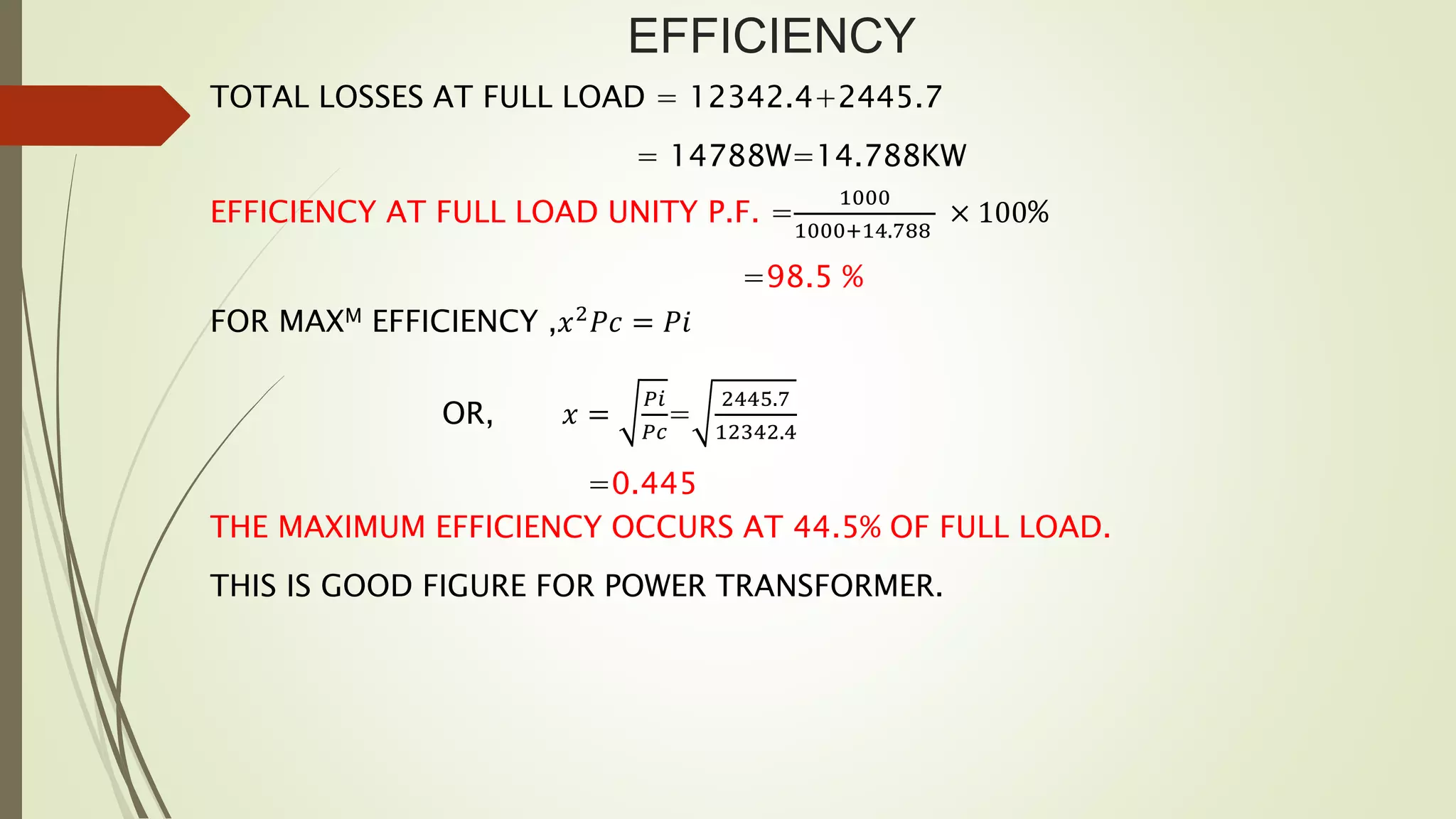

- Calculations of losses, efficiency, and temperature rise

- Dimensions of the transformer and its components like the core, windings, and tank

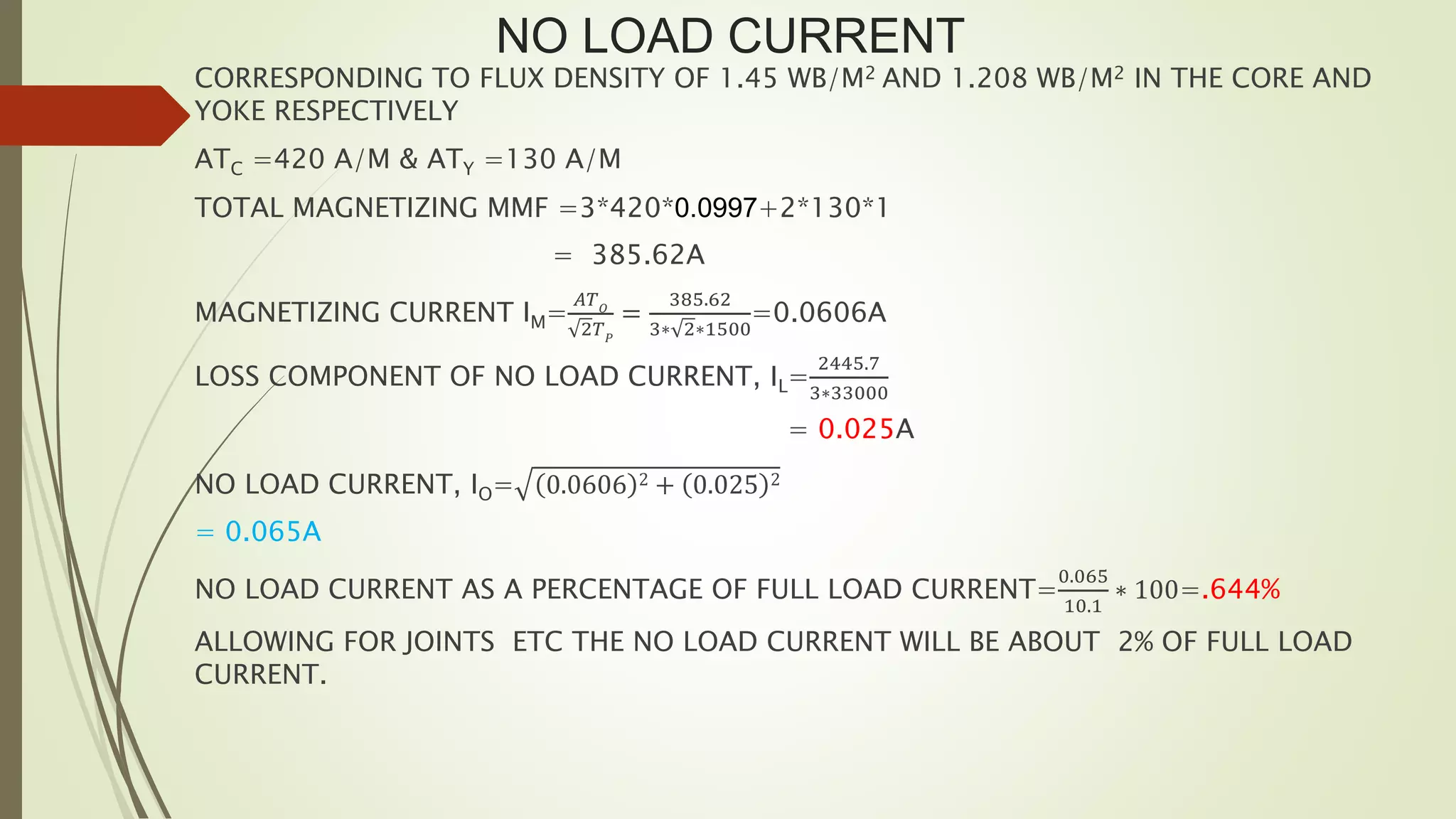

- Additional specifications like no load current and impedance voltage are verified to meet requirements.

![EE 3220 Electrical Machine Design

Project on Transformer Design

Submitted To:

DR.MD.HABIBULLAH

PROFESSOR,

DEPT OF EEE,

KUET

MD.ABU SAYED JANNATUL ISLAM

ASSISTANT PROFESSOR,

DEPT OF EEE,

KUET

Submitted by:

Group – 13

Members:

1. Mainul Islam [1703032]

2. Asif Rahman [1703046]

3. Asif Adnan Tajwer [1703069]

4. Al Mamun Sarker [1703070]

Date of Submission: 18 June 2021](https://image.slidesharecdn.com/machinedesign-powertransformerdesign-210618152227/75/Electrical-Machine-design-1-2048.jpg)