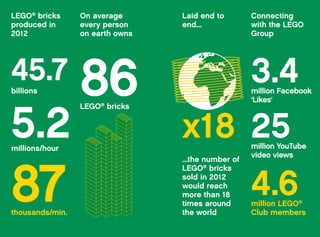

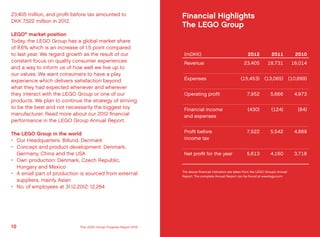

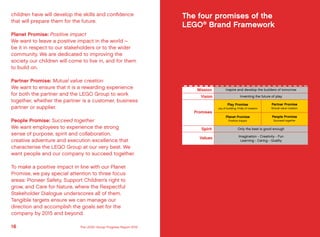

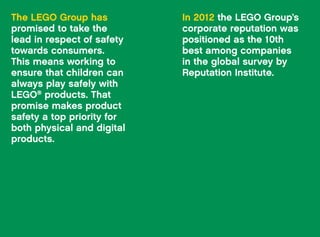

The LEGO Group had $45.7 billion in sales in 2012, producing over 86,000 LEGO bricks per minute. If stacked end to end, the bricks sold in 2012 would circle the earth over 18 times. The LEGO Group connects with customers through social media, with over 3.4 million Facebook likes and 25 million YouTube views. The document provides an overview of the LEGO Group's business highlights in 2012, its commitment to sustainability, engagement with stakeholders, and financial performance.