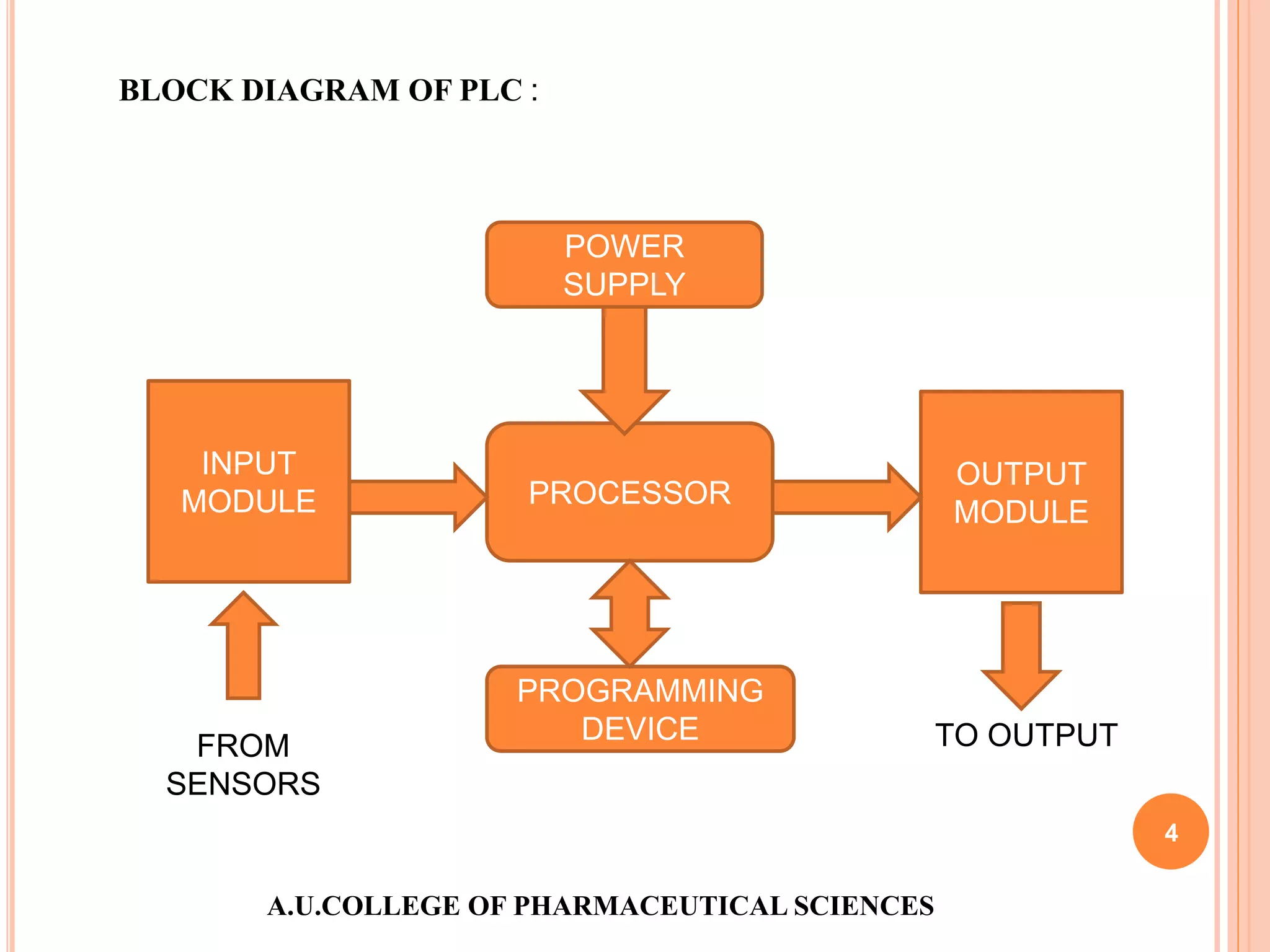

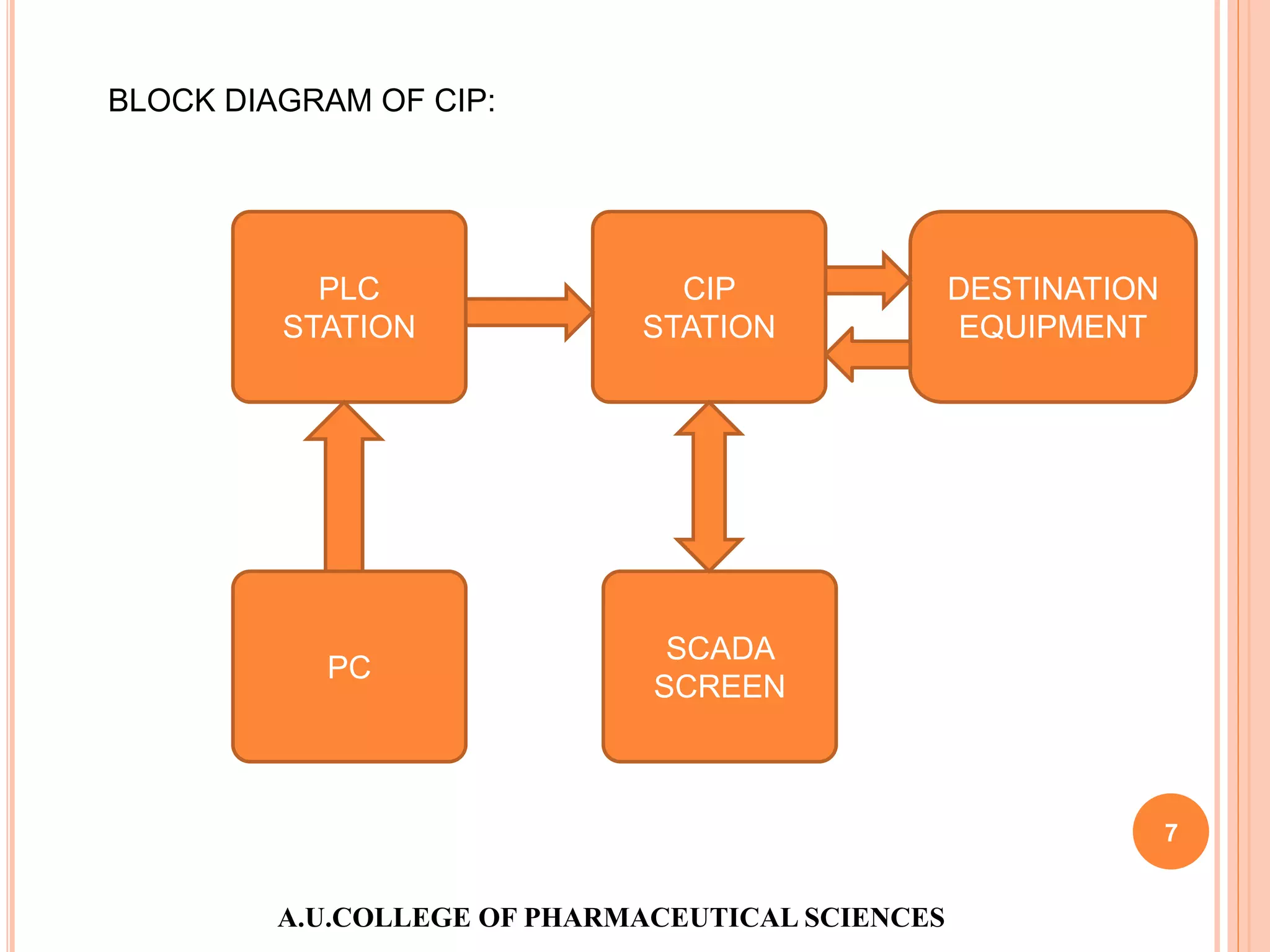

The document discusses the role of programmable logic controllers (PLCs) in industrial automation and their application in cleaning processes within the pharmaceutical industry. PLCs serve as microprocessor-based systems that enable flexible control of manufacturing processes with minimal programming knowledge required, ultimately enhancing product quality and plant hygiene. The use of PLCs in cleaning in place (CIP) systems significantly reduces human involvement, operational time, and labor costs.