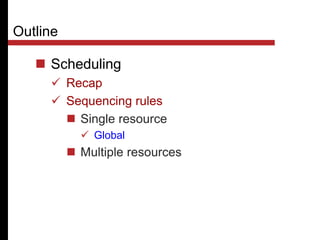

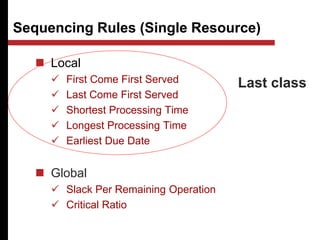

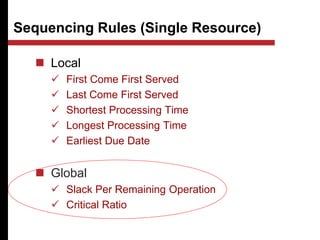

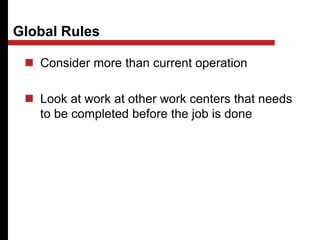

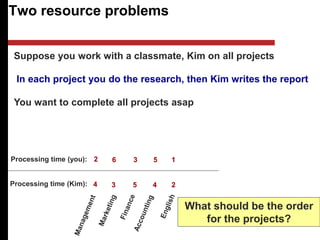

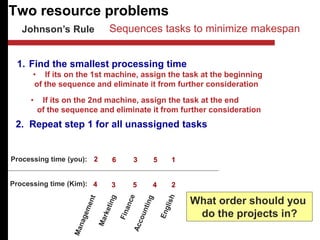

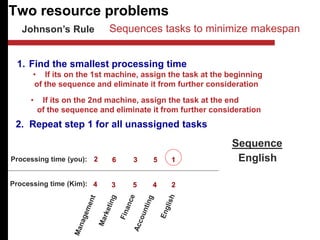

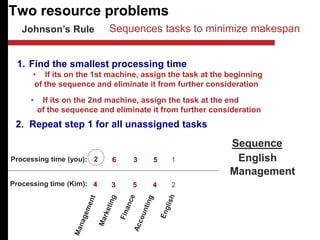

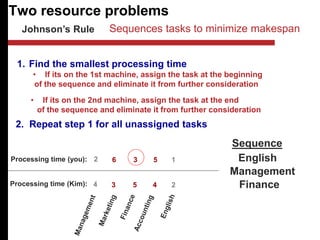

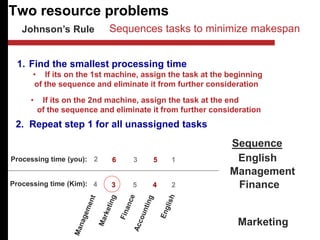

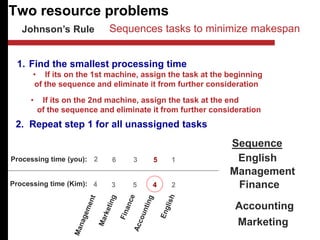

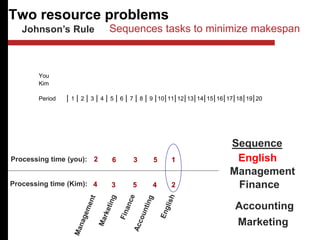

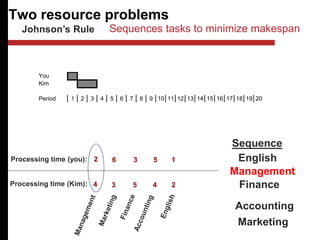

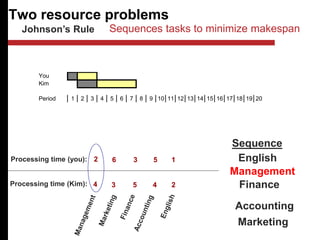

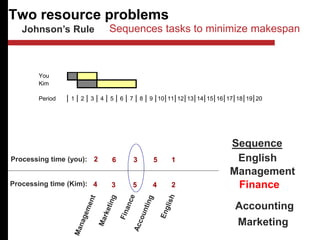

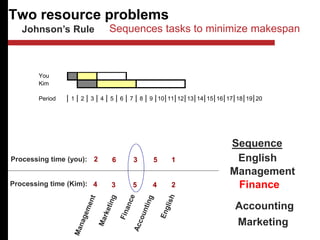

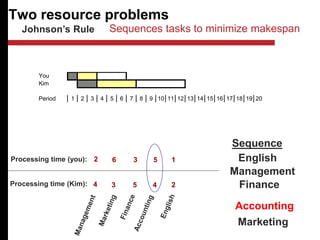

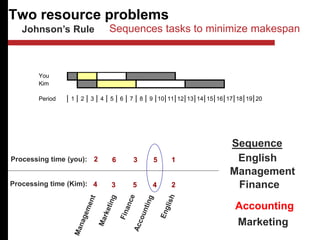

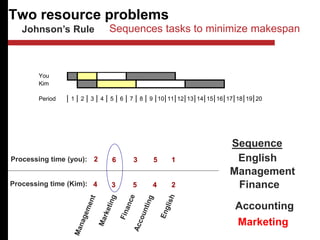

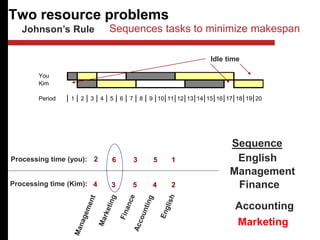

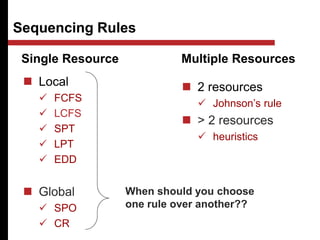

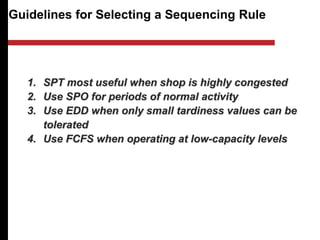

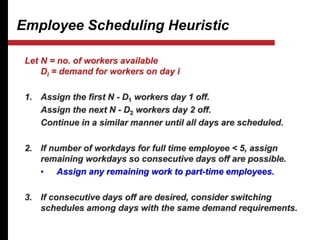

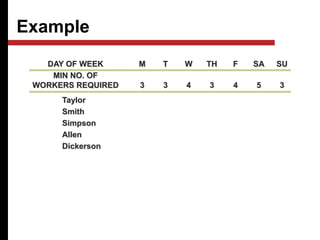

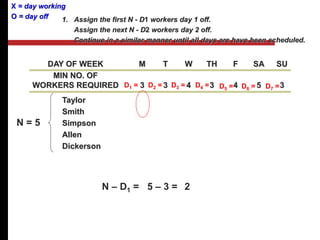

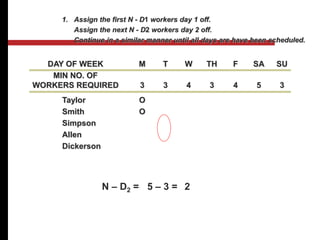

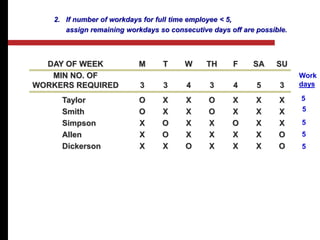

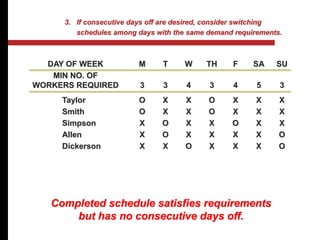

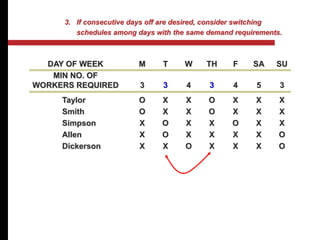

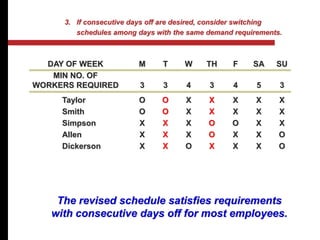

Scheduling deals with determining the timing and order of operations or jobs. There are different types of sequencing rules that can be used for scheduling, including both local rules that consider a single resource and global rules that look at the entire job. When scheduling across multiple resources, Johnson's rule aims to minimize the makespan by sequencing tasks based on their processing times on each resource. For employee scheduling, a common heuristic is to assign workers days off starting with the days that require the fewest workers, aiming to provide full-time employees with at least 5 work days and consecutive days off when possible.