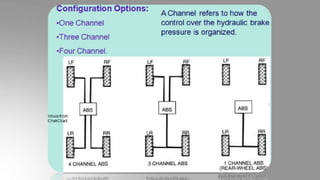

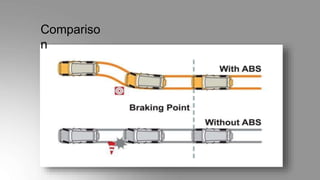

The document discusses anti-lock braking systems (ABS). It provides an overview of ABS, including its history, components, principles of operation, types, and advancements like electronic stability control. ABS prevents wheel locking under heavy braking, allowing the driver to steer and maintain vehicle control. It modulates brake pressure to keep wheels rotating at an optimal slip rate for maximum braking force. ABS improves safety by reducing skidding and keeping vehicles stable during emergency stops on slippery surfaces.

![Principles of

ABS

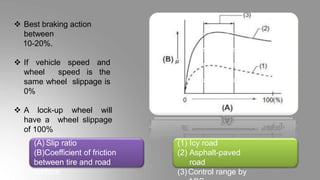

When brakes applied- vehicle speed comes down

Decrease in vehicle speed not always proportional to decrease in wheel

speed

Non-correspondence - Slip

Magnitude measured as Slip ratio

Slip ratio = [(Vehicle speed – Wheel speed)/Vehicle speed ]× 100%

When

Slip ratio = 0% : Vehicle speed corresponds exactly to wheel speed

Slip ratio = 100% : Wheels locked - vehicle moves](https://image.slidesharecdn.com/abs-230709164051-88de6c93/85/ABS-pptx-9-320.jpg)

![ABS Components

Overview

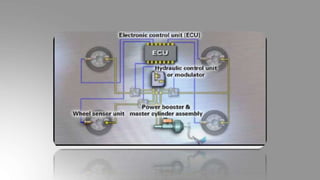

1.Hydraulic Unit

2.Electronic Brake Control Module

[EBCM] 3.Four wheel speed sensors

4.Interconnecting wiring

5.ABS indicator](https://image.slidesharecdn.com/abs-230709164051-88de6c93/85/ABS-pptx-12-320.jpg)