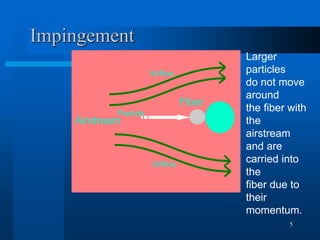

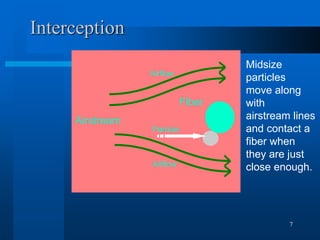

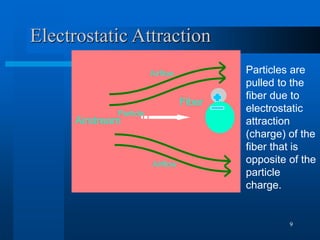

This document discusses residential air filtration. It begins by outlining some key residential air filtration issues like removing particulates and odors while maintaining airflow. It then describes various principles of air filtration like straining, impingement, interception, diffusion, and electrostatic attraction/precipitation that can remove particles. It provides diagrams to illustrate these principles. The document also discusses standards for residential air filters from ASHRAE and how filters are tested and assigned a Minimum Efficiency Reporting Value (MERV) rating. Finally, it considers pressure drop and airflow reduction that can occur with higher efficiency filters.