The document outlines the challenges and solutions associated with production scheduling in a plastic bag manufacturing environment using Microsoft Dynamics AX 2009. It includes a fit-gap analysis between standard scheduling features and the operational realities of the manufacturing process, identifying deficiencies such as the inability to dynamically assign operations to movable equipment. The author proposes a need for enhancements and customizations to improve the effectiveness of the scheduling engine for job shop settings.

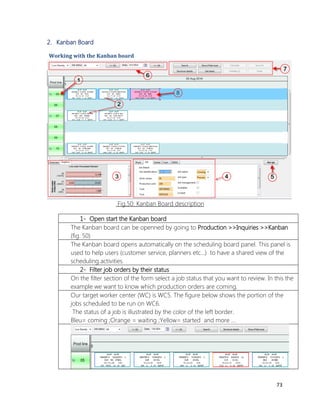

![43

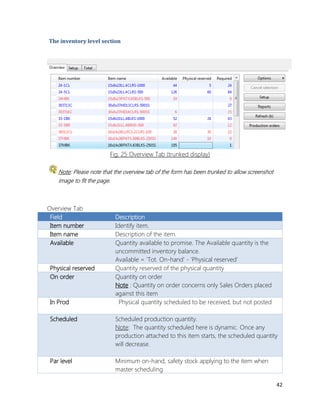

Required Quantity needed to fulfill actual requirement. Required Quantity calculation= Total On-hand - Physically Reserved -On Order- PAR level

To Production

Quantity to be sent to production

To Production = Max (Required; Skid Qty; Min Inventory Qty.) Split Use the Split option to split the quantity that is needed to produce 2 production orders. Note: the split quantity = Max ( Split Qty; Min Inventory Qty; Skid Qty)

Num. of Prod

Number of production , this field helps creating multiple production orders at once Select This check box allows the users to "Firm" the quantity required and then create a production order

Skid qty

Displays the quantity of cases on skid or pallet Net weight Net weight of one case

Skid Weight

Skid Net Weight (we don’t consider here the tare weight) Prod Weight Compute here the production order ‘s weight

Setup Tab

Total Tab Field Description Required Quantity needed to fulfill actual requirement. Required Quantity calculation= [Total On-hand] – [Physically Reserved] + [Scheduled]- [On Order]- PAR level Field Description Item group Item group that the item is attached to.

Coverage group

Group that determines how a requirement is calculated for the item. Buyer group Identification of the buyer's group.

Quantity per layer

Quantity per layer on standard pallet Net weight Net weight of inventory item for one inventory unit

Par level

Minimum on-hand, safety stock applying to the item when master scheduling](https://image.slidesharecdn.com/productionschedulingdax2009-141002093223-phpapp01/85/Production-Scheduling-Using-Microsoft-Dynamics-AX-44-320.jpg)