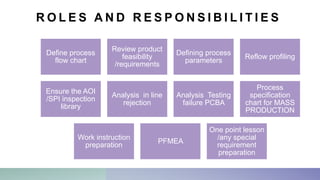

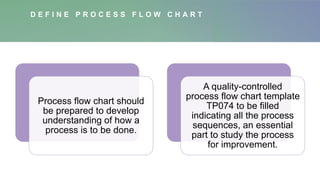

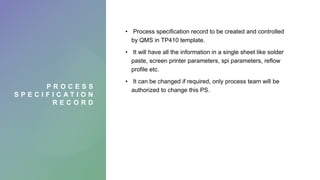

The document outlines the roles and responsibilities of a process team in developing and optimizing a surface mount technology (SMT) process to enhance quality, reduce scrap, and improve productivity. Key activities include defining process flow charts, establishing product feasibility requirements, documenting process parameters, and conducting analyses of test failures and reflow profiles. The document emphasizes the importance of controlled templates for work instructions and process specifications to ensure compliance and continuous improvement.