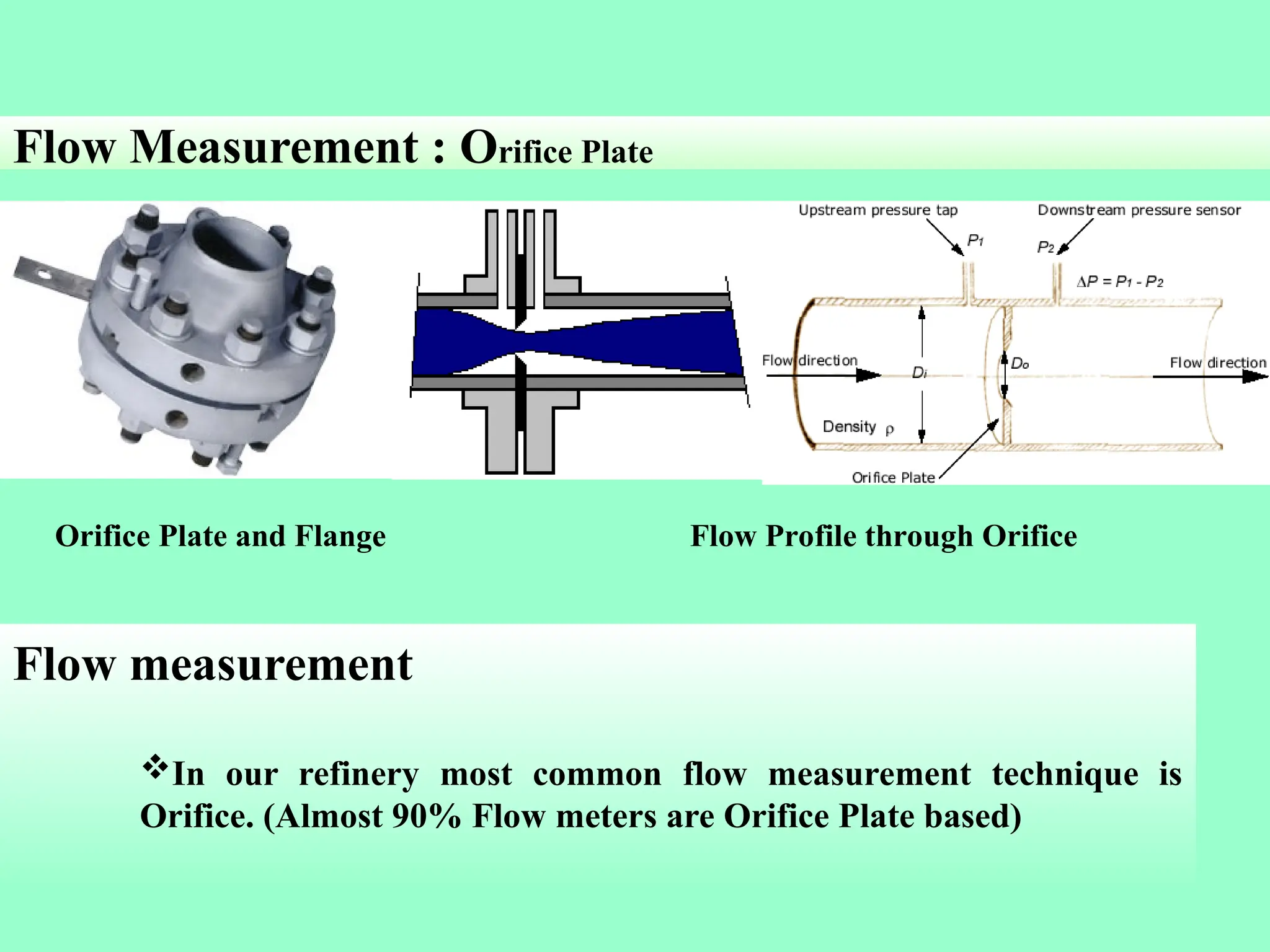

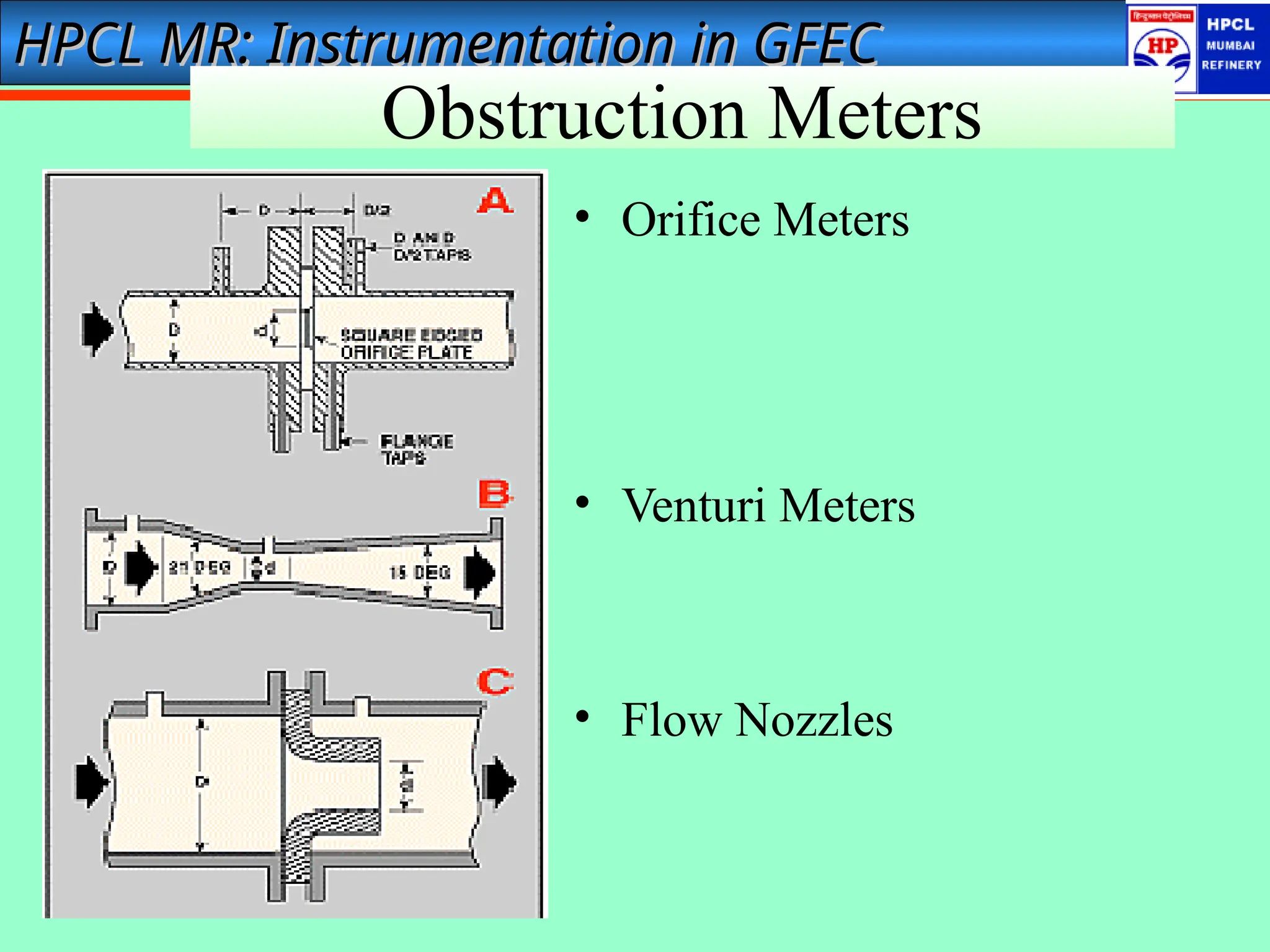

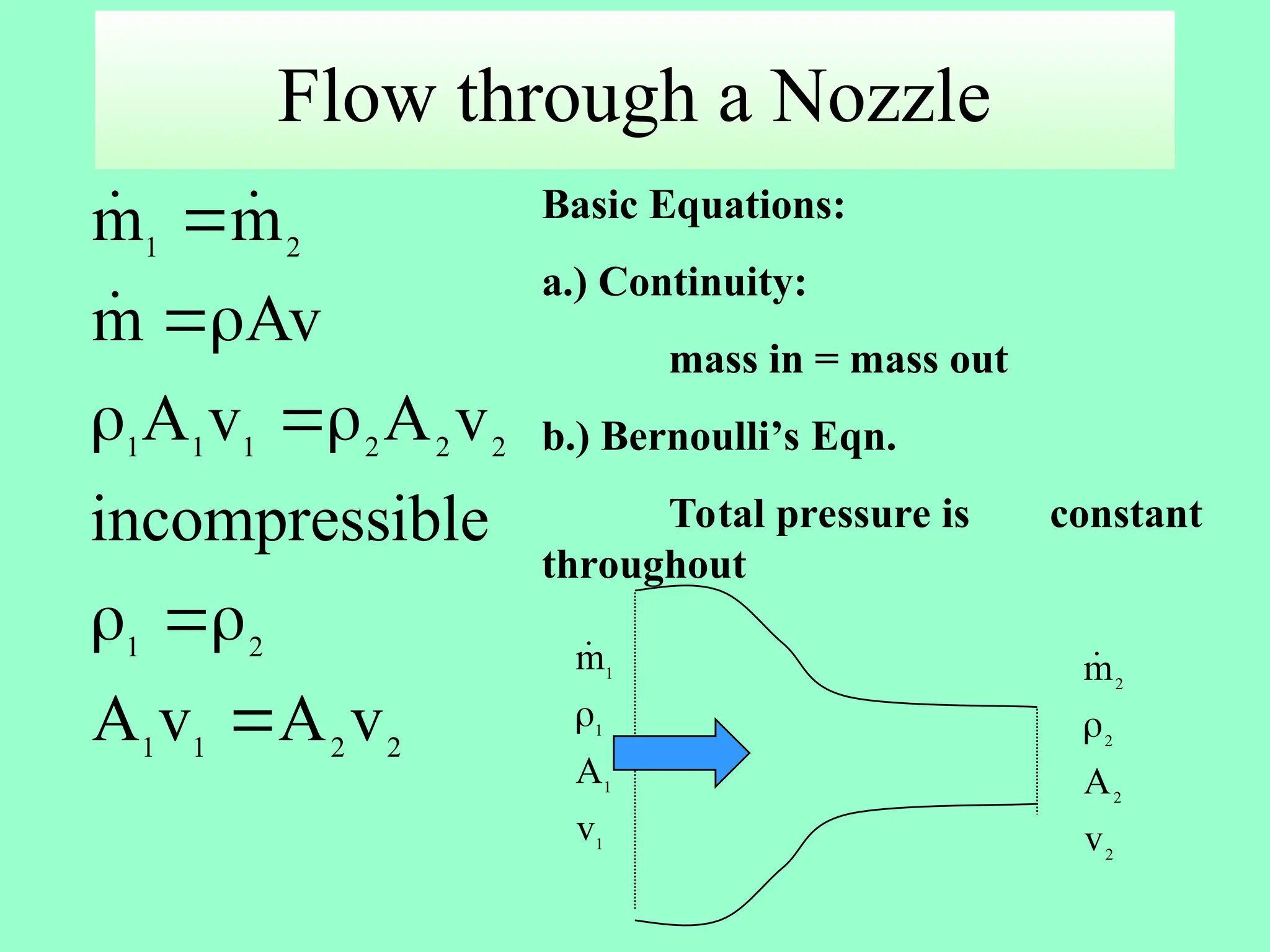

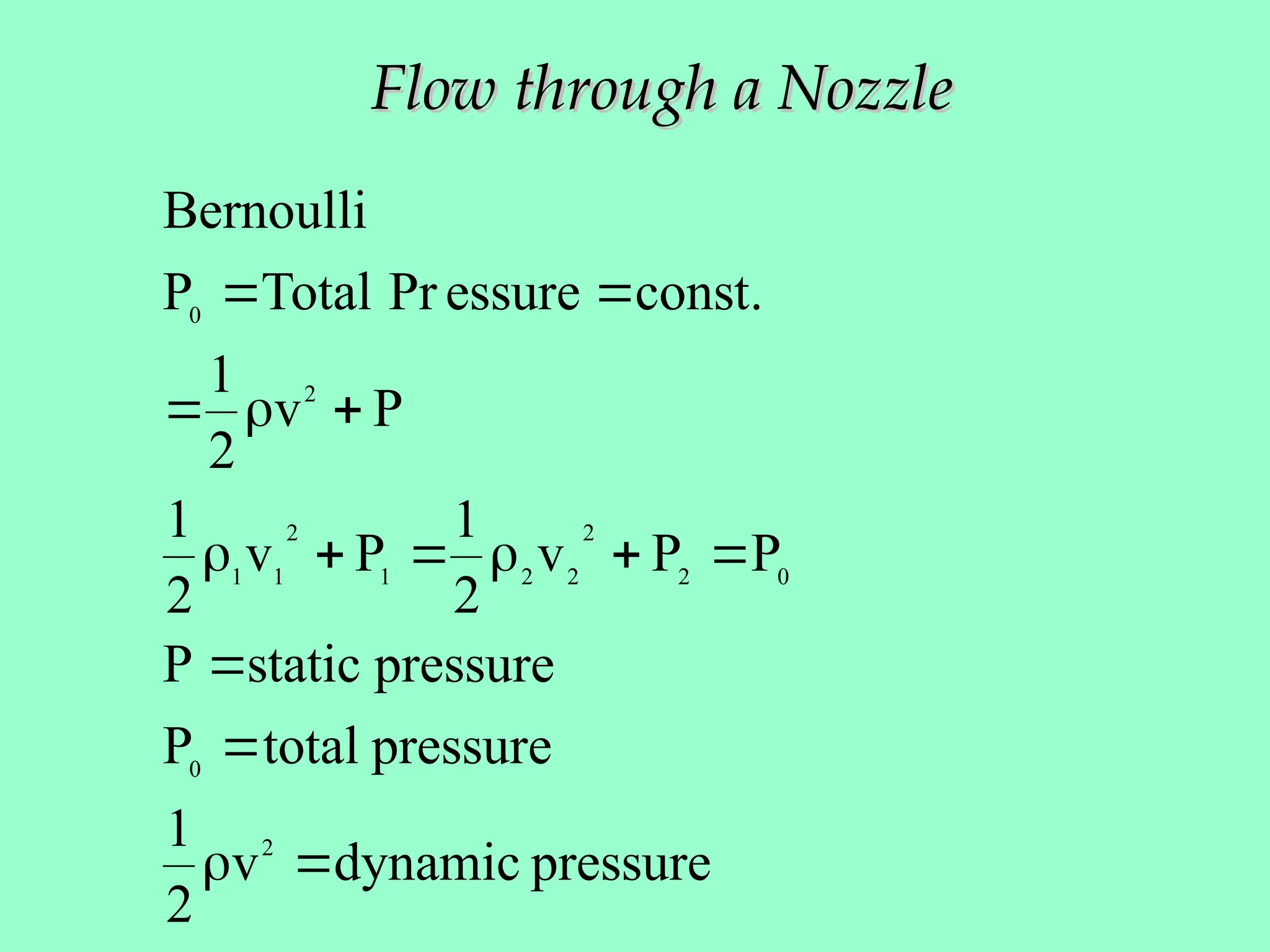

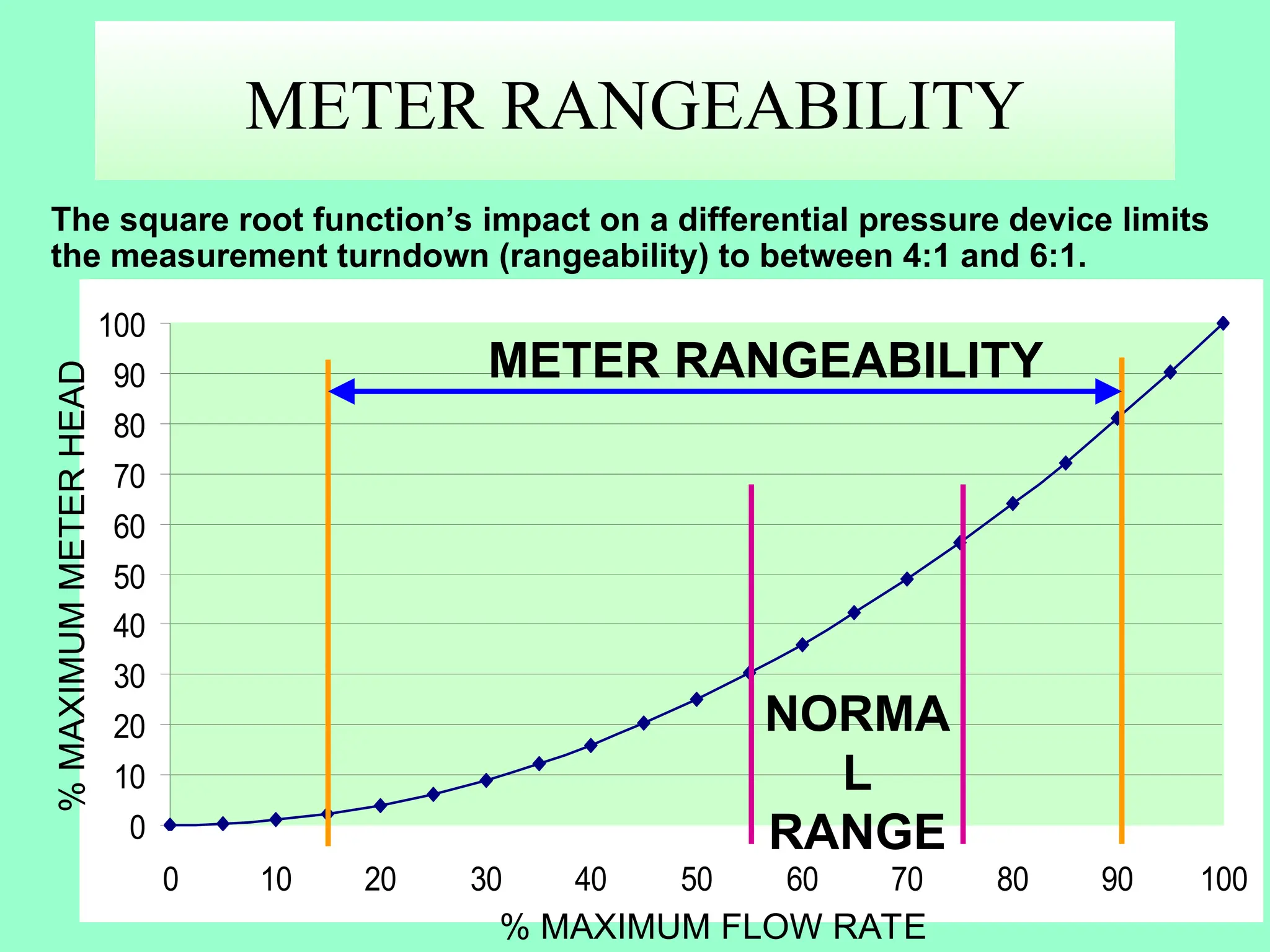

The document details flow measurement technologies, specifically focusing on orifice plates as the predominant technique used in refineries, accounting for about 90% of flow meters. It discusses basic equations governing flow, installation requirements for orifice and venturi meters, and factors affecting measurement rangeability. Additionally, it covers the necessity of vent and drain holes to manage unwanted liquid or gas during measurement.