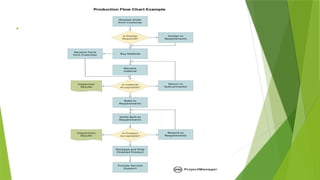

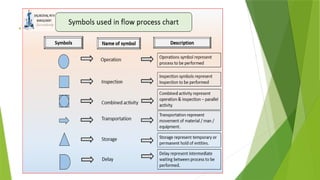

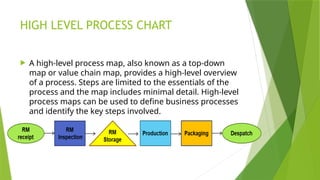

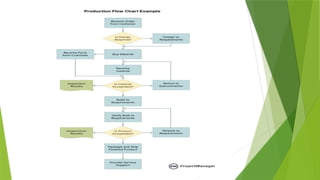

A process chart is a visual tool that outlines the steps in a production process, aiding in understanding and identifying areas for improvement. There are two main types of process charts: high-level and detailed, each serving distinct purposes in process mapping. Benefits of using process flowcharts include enhanced clarity, efficiency, error reduction, improved communication, and valuable documentation for compliance.