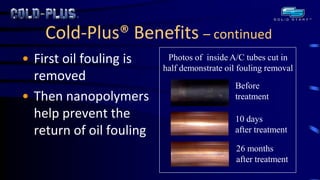

The document introduces Cold-Plus®, a patent-pending A/C and refrigeration treatment from the Solid Start family, which reduces oil fouling and improves heat transfer efficiency, ultimately extending equipment life and reducing operational costs. Cold-Plus® enhances thermodynamic processes and prevents the reoccurrence of oil fouling through a unique PTFE treatment and nanopolymers. Test documentation supports its effectiveness in improving thermal transfer, reducing maintenance costs, and ensuring a favorable return on investment.