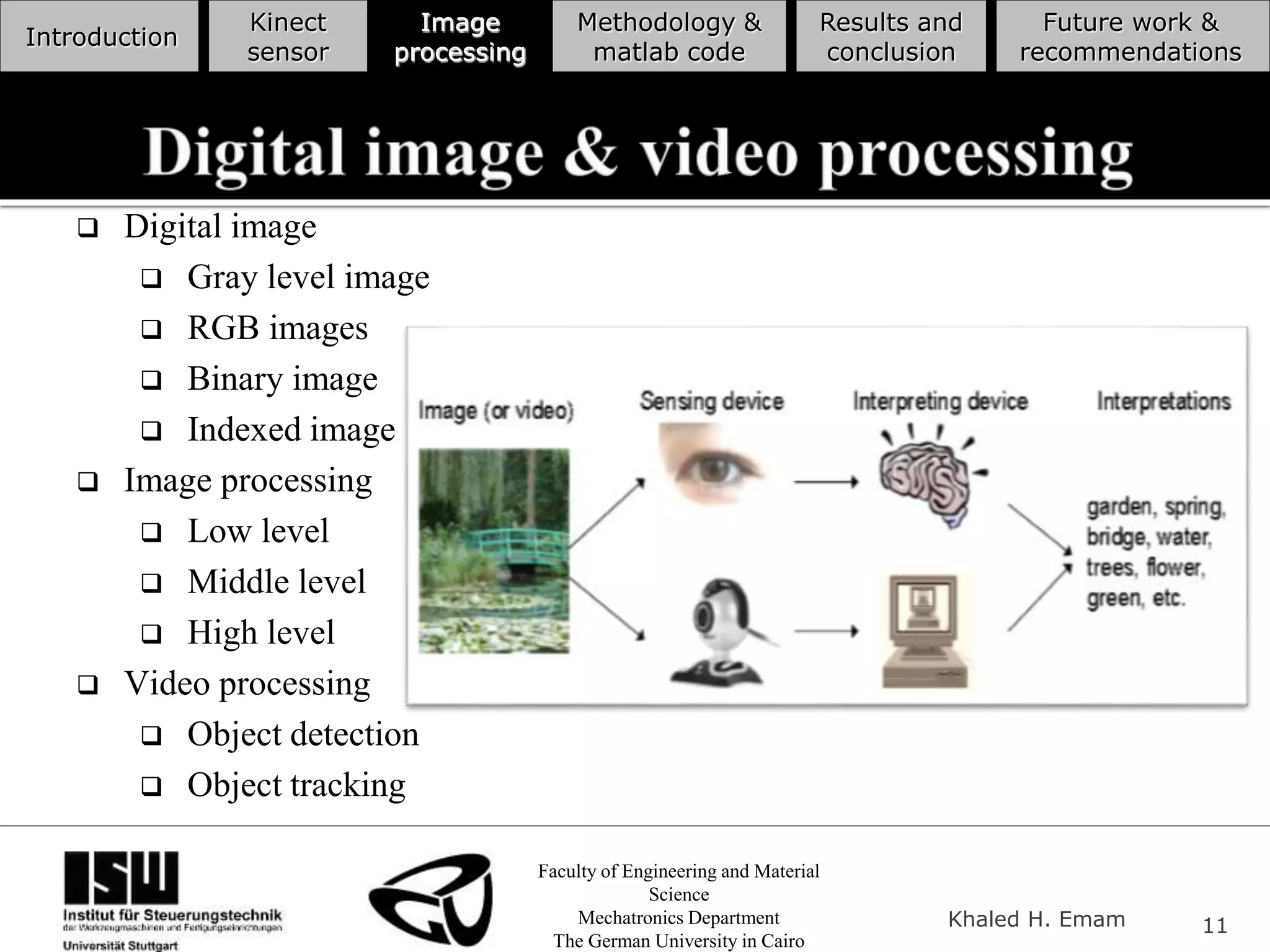

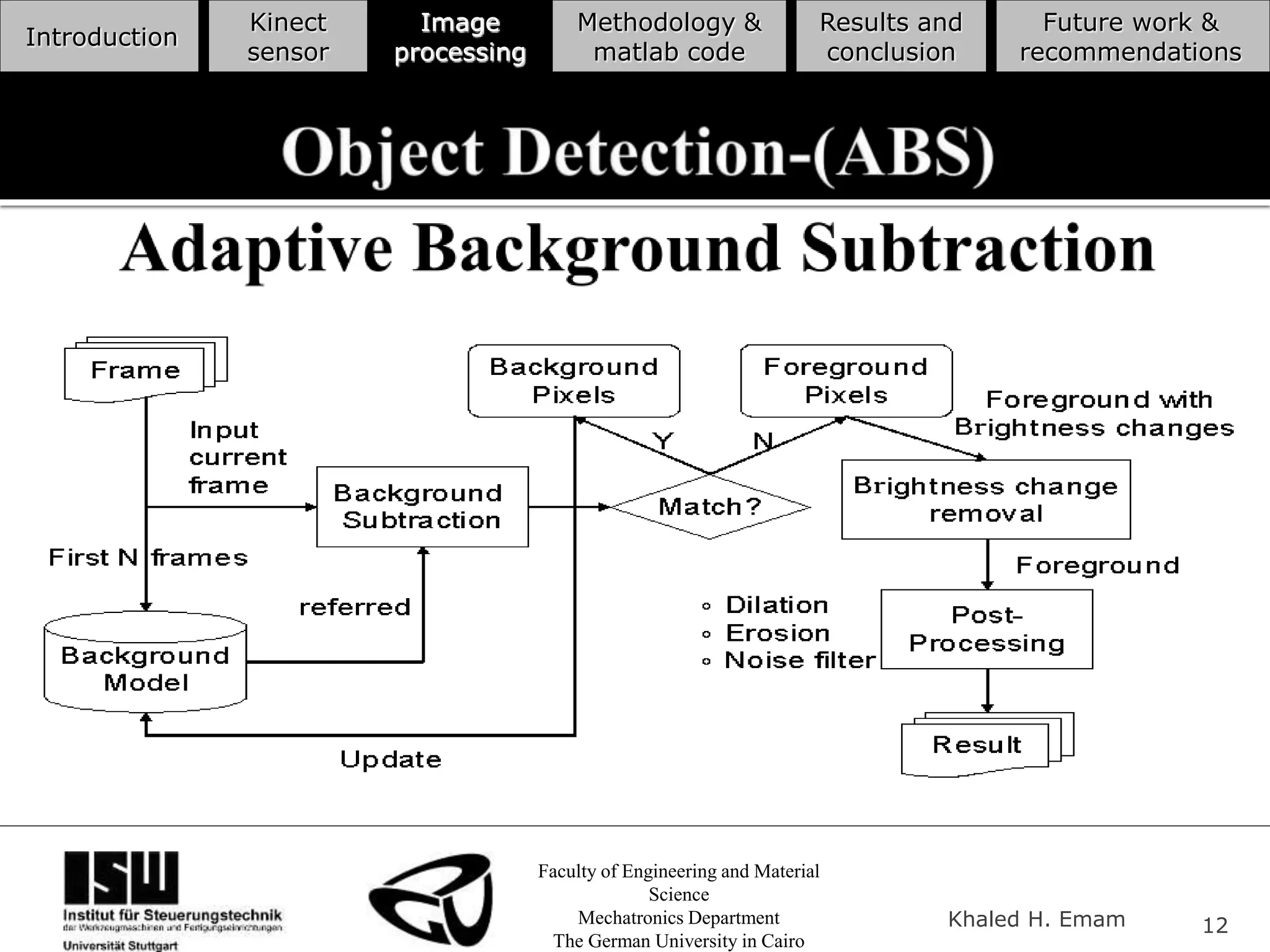

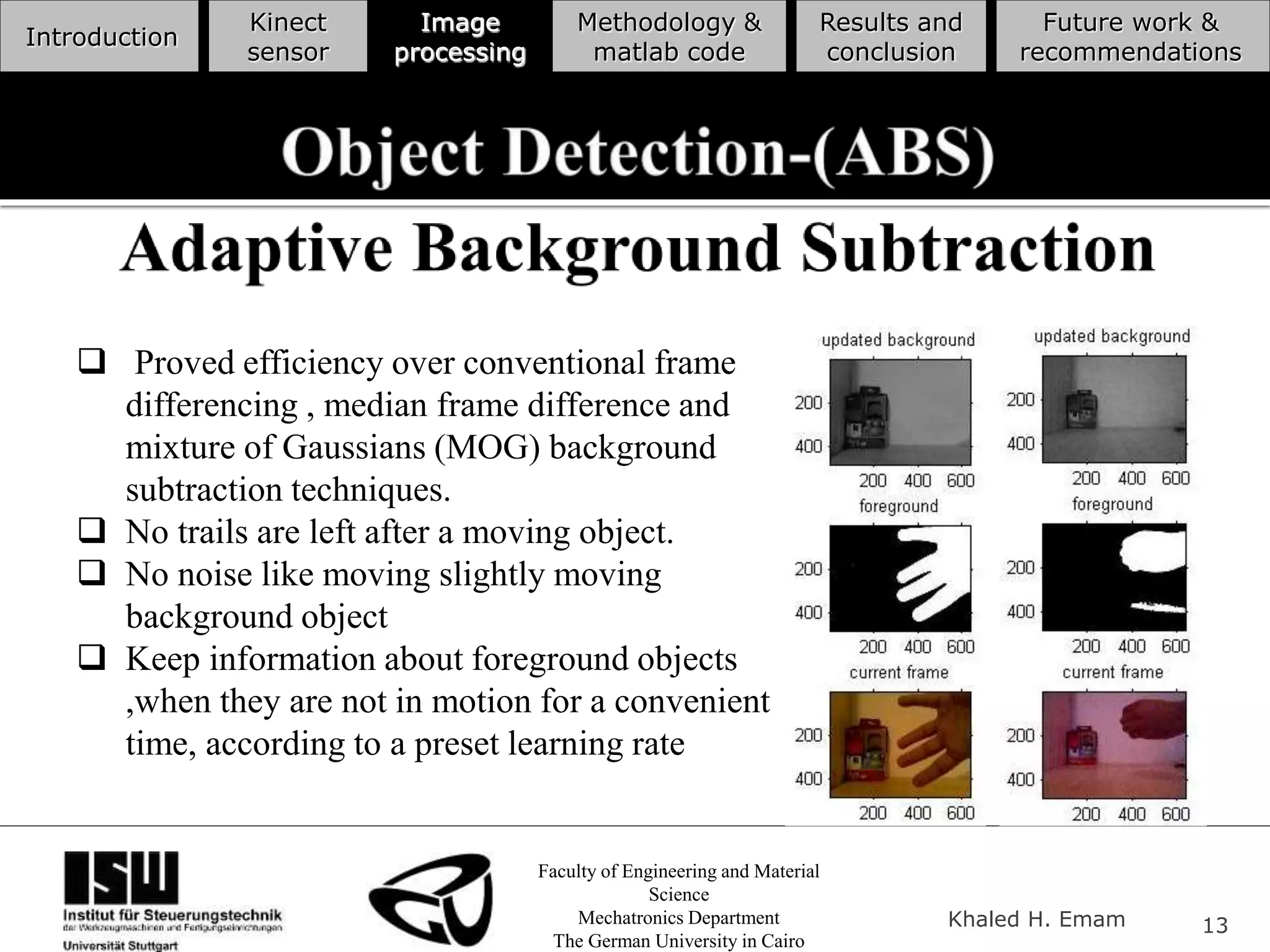

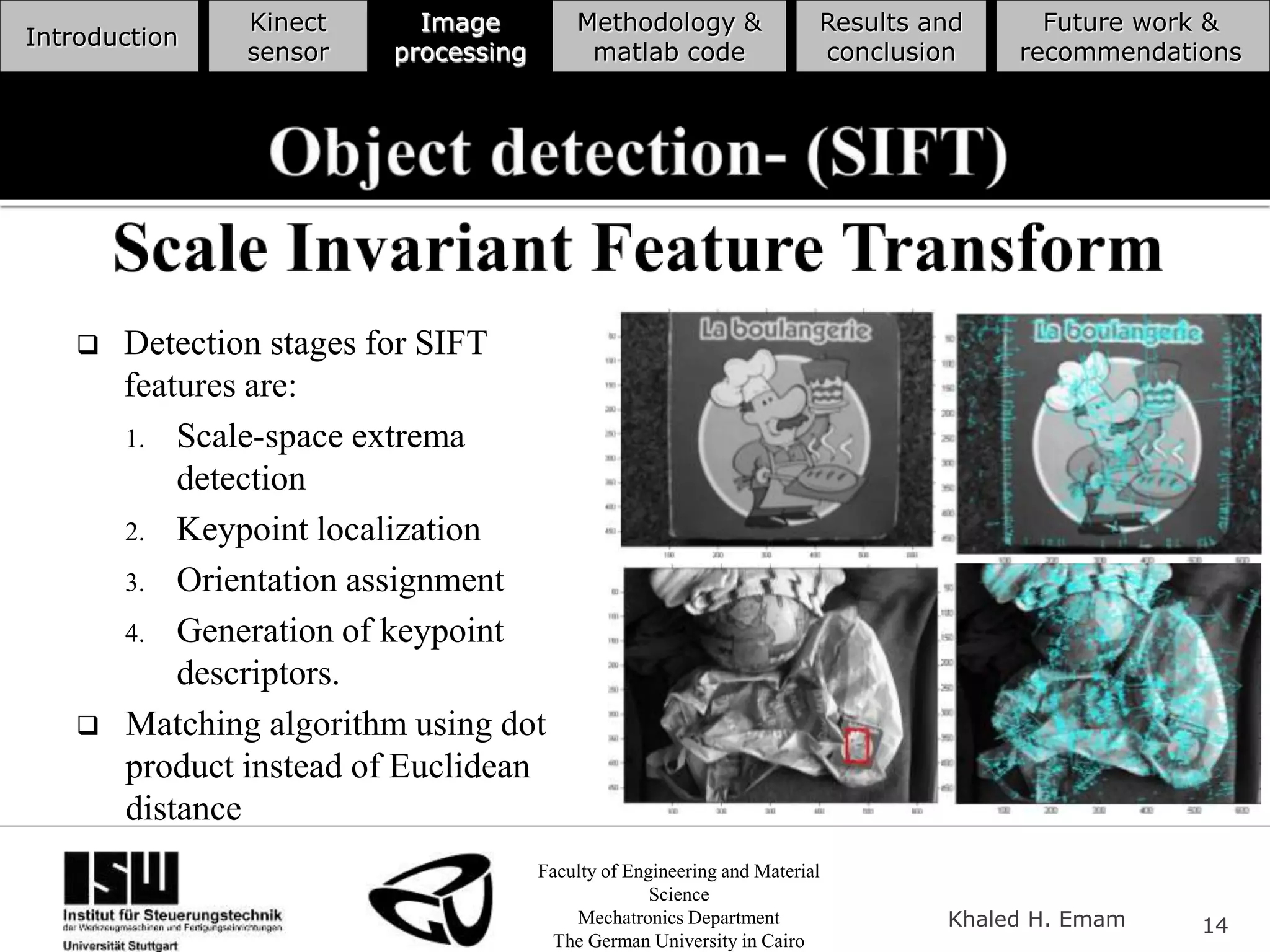

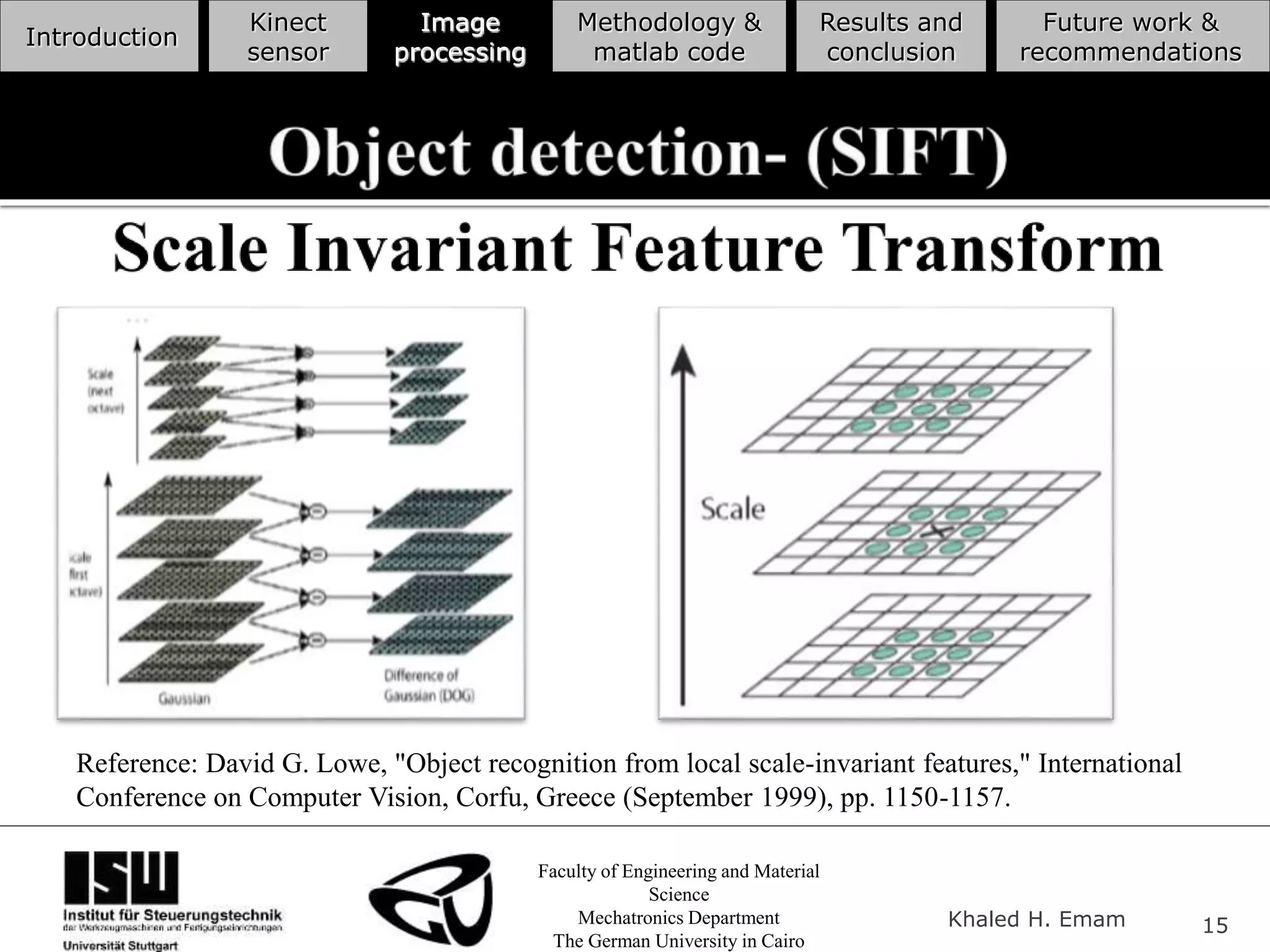

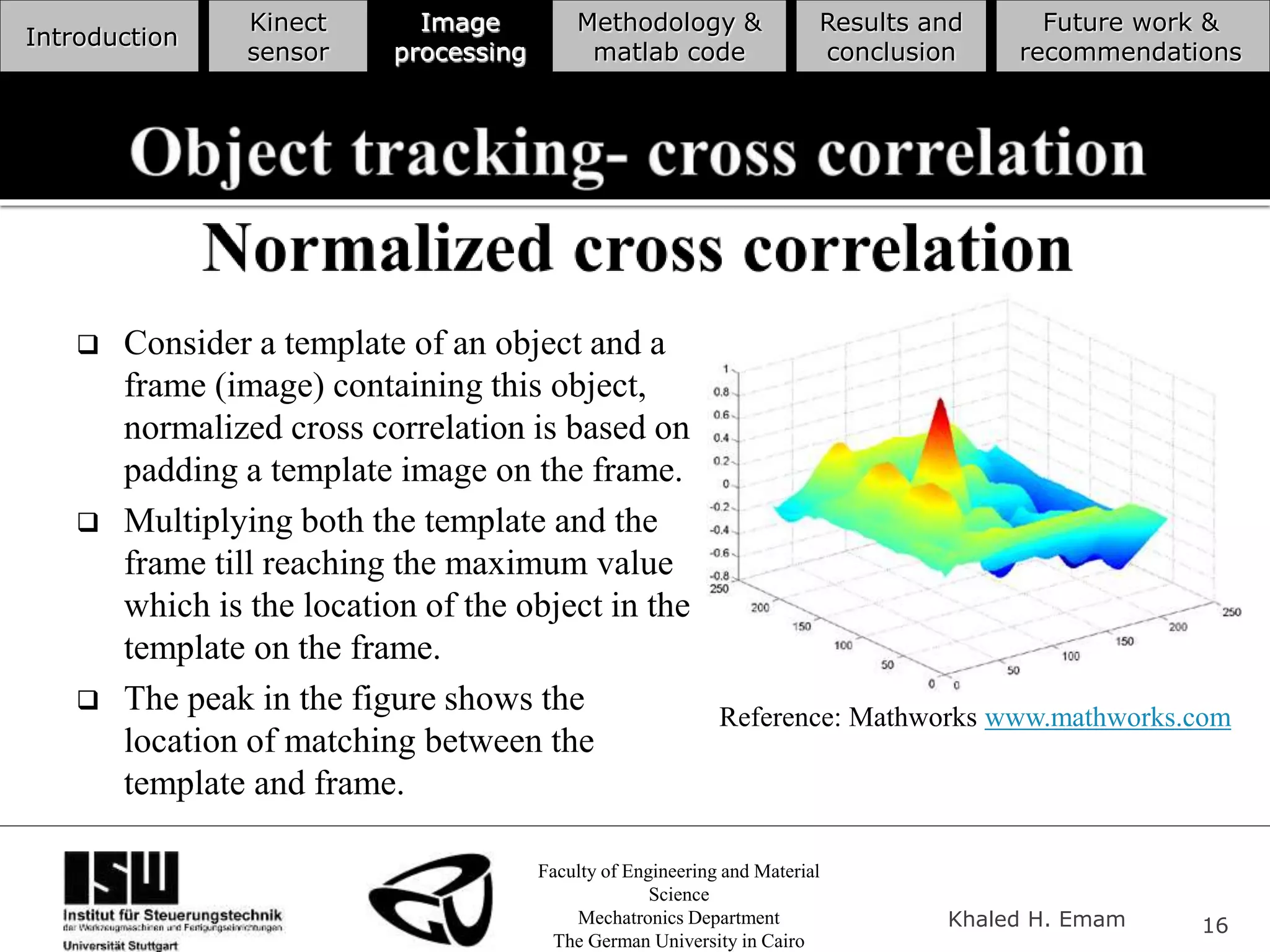

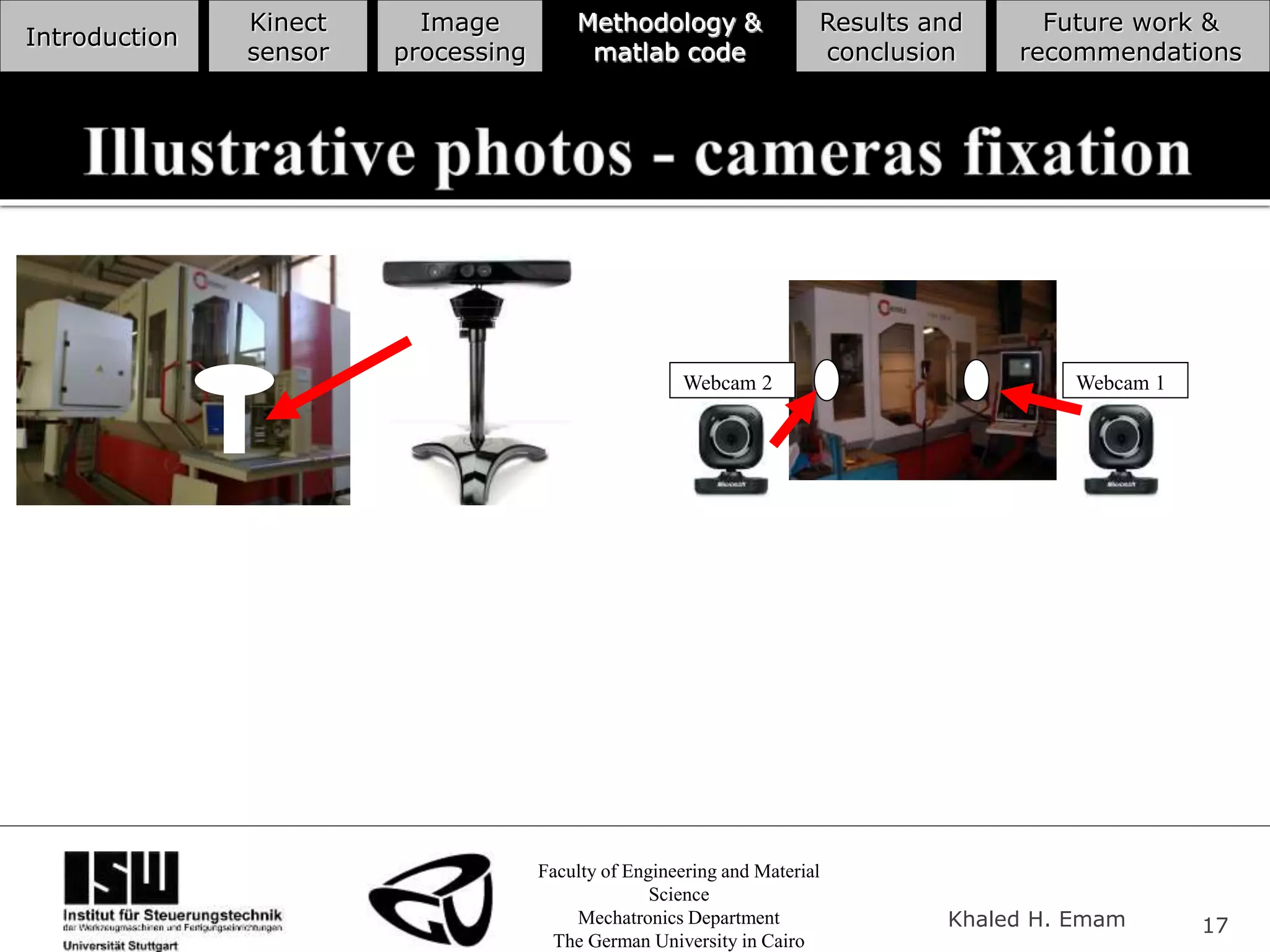

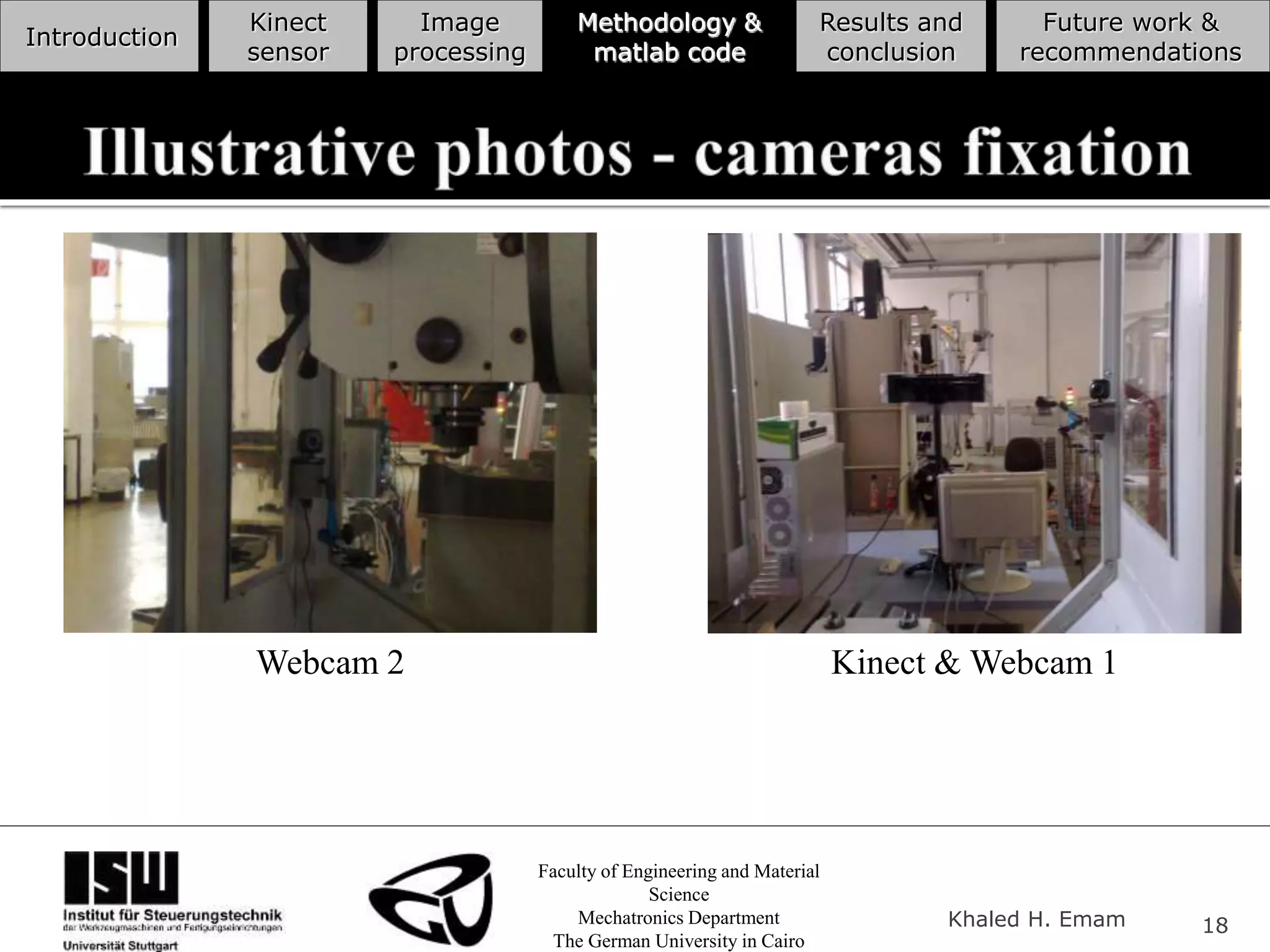

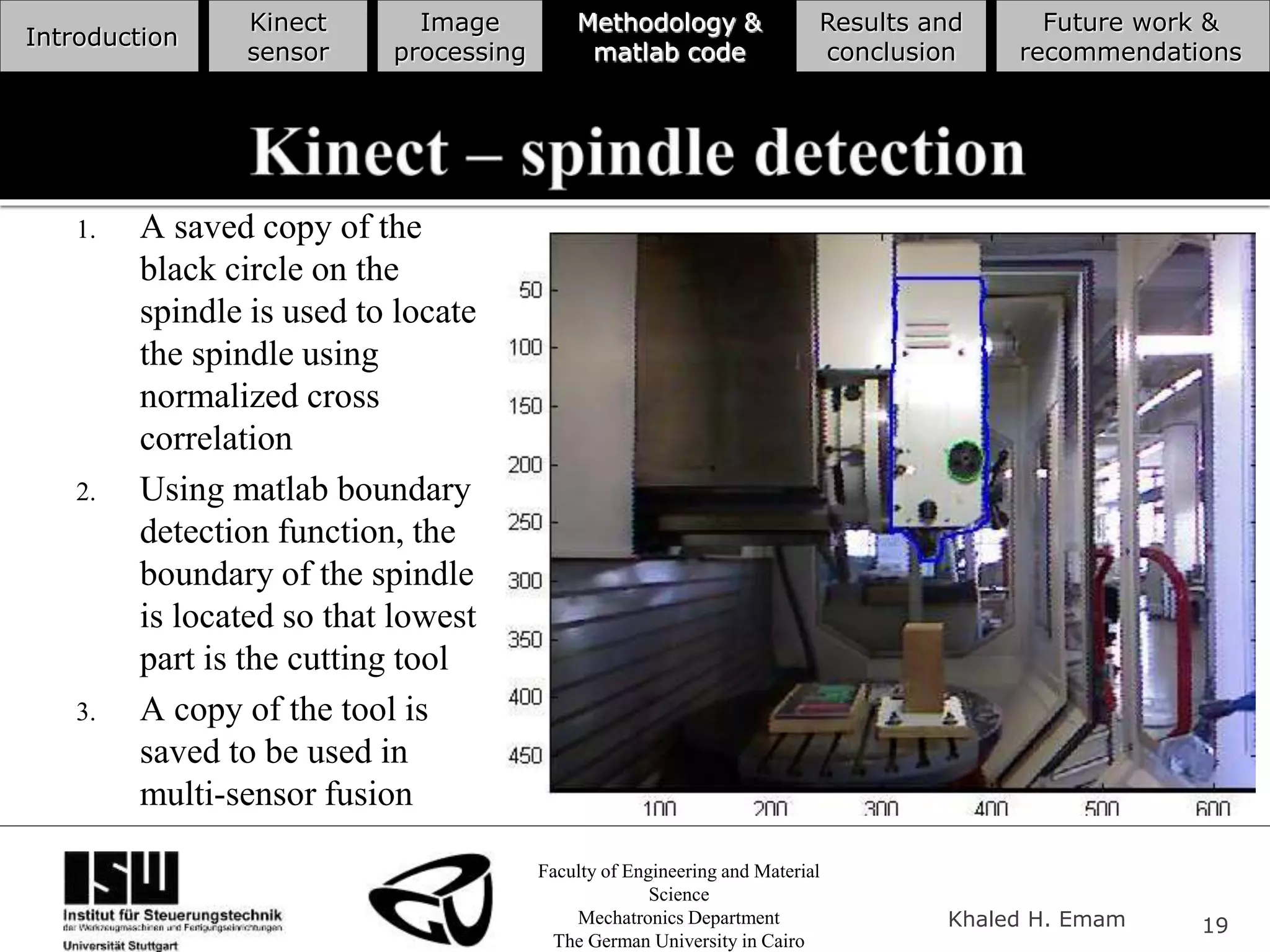

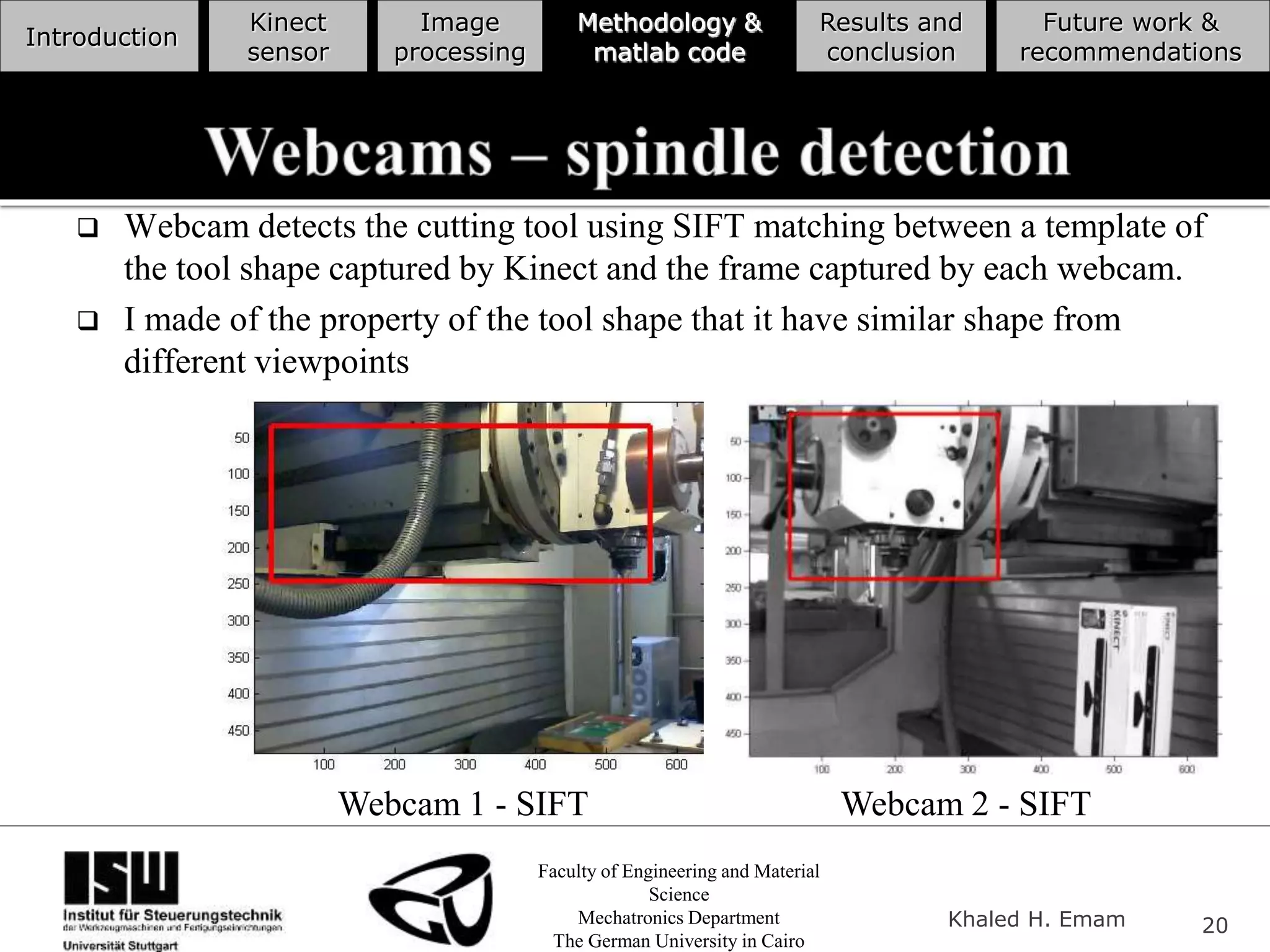

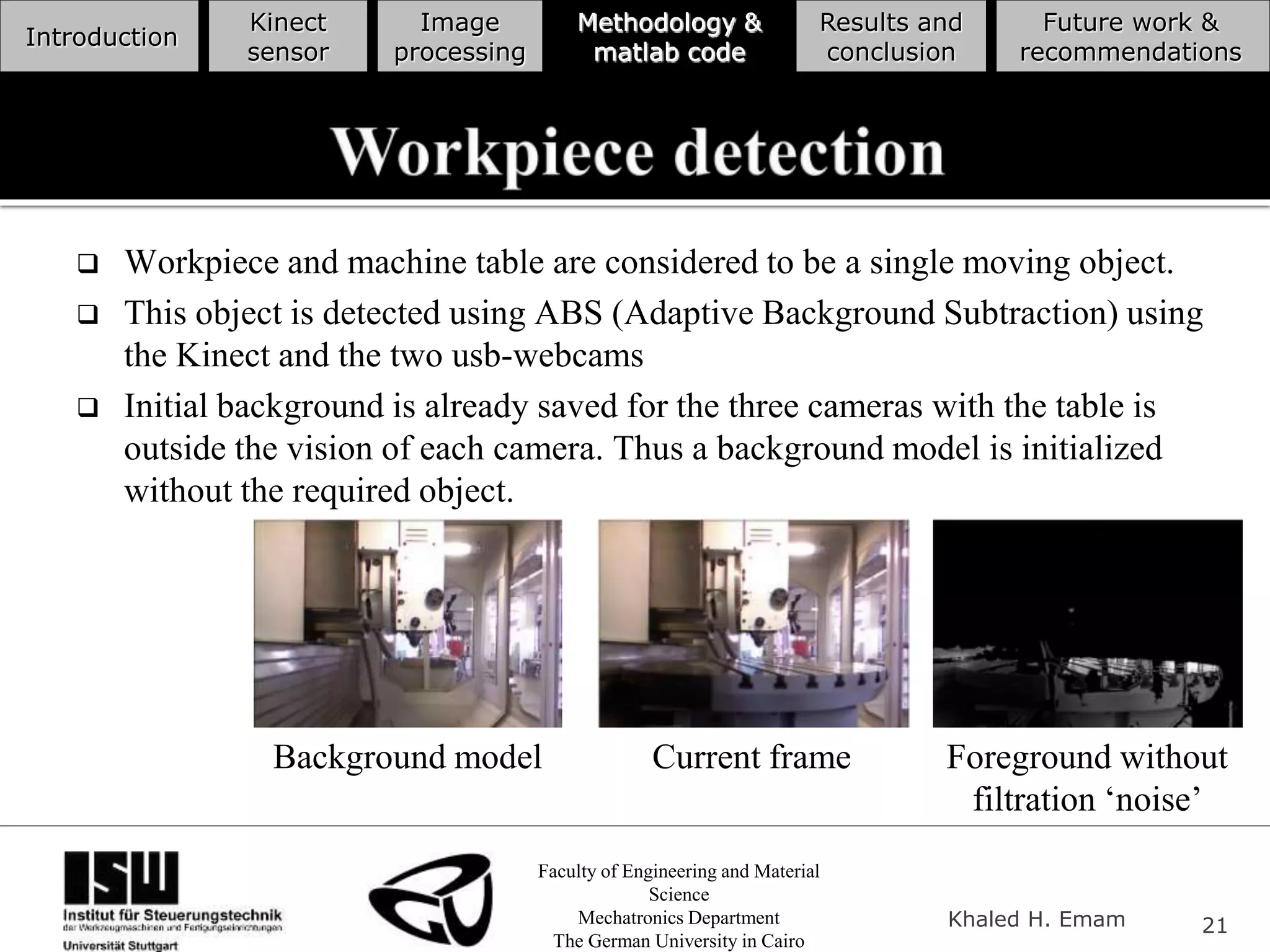

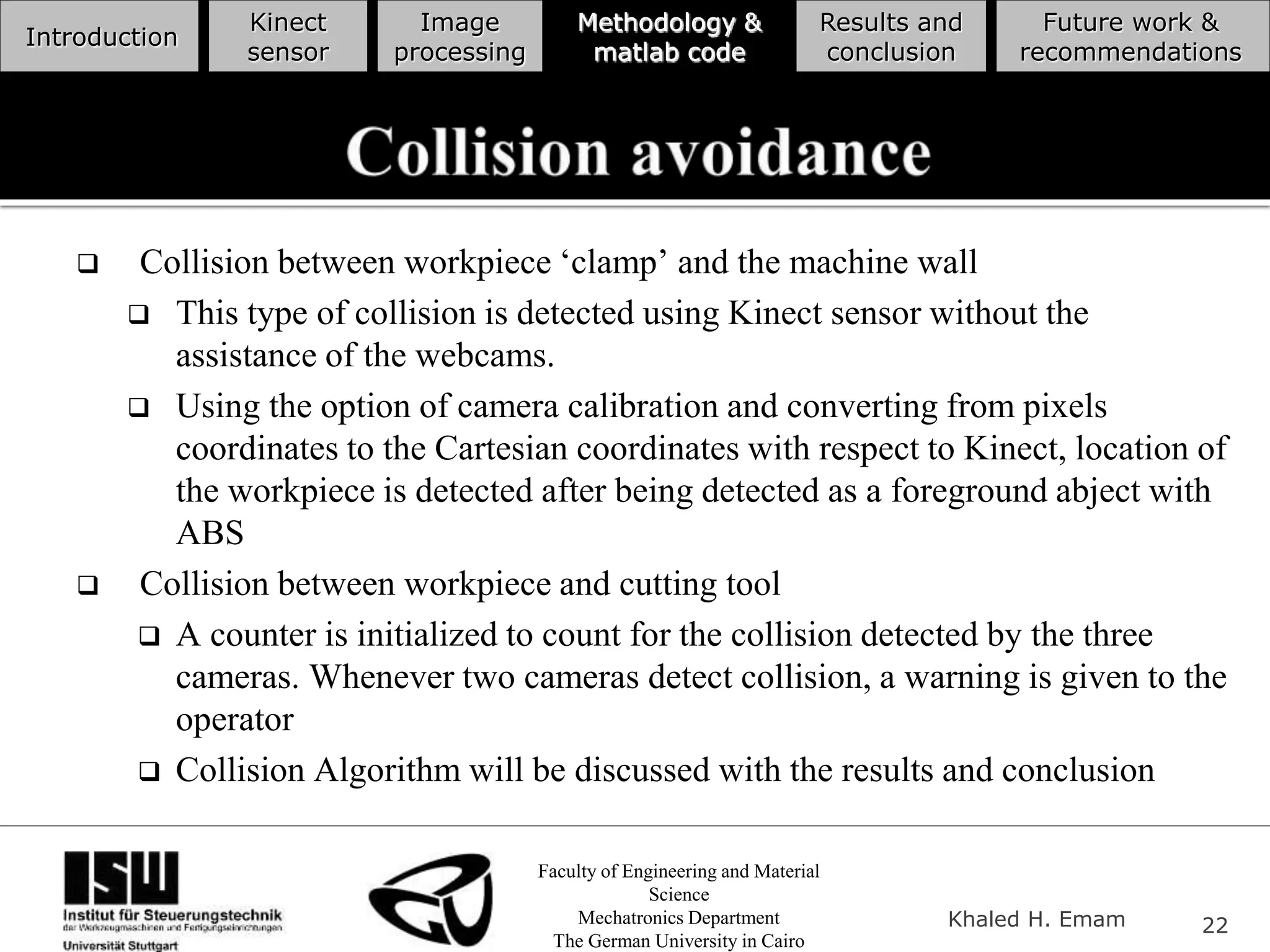

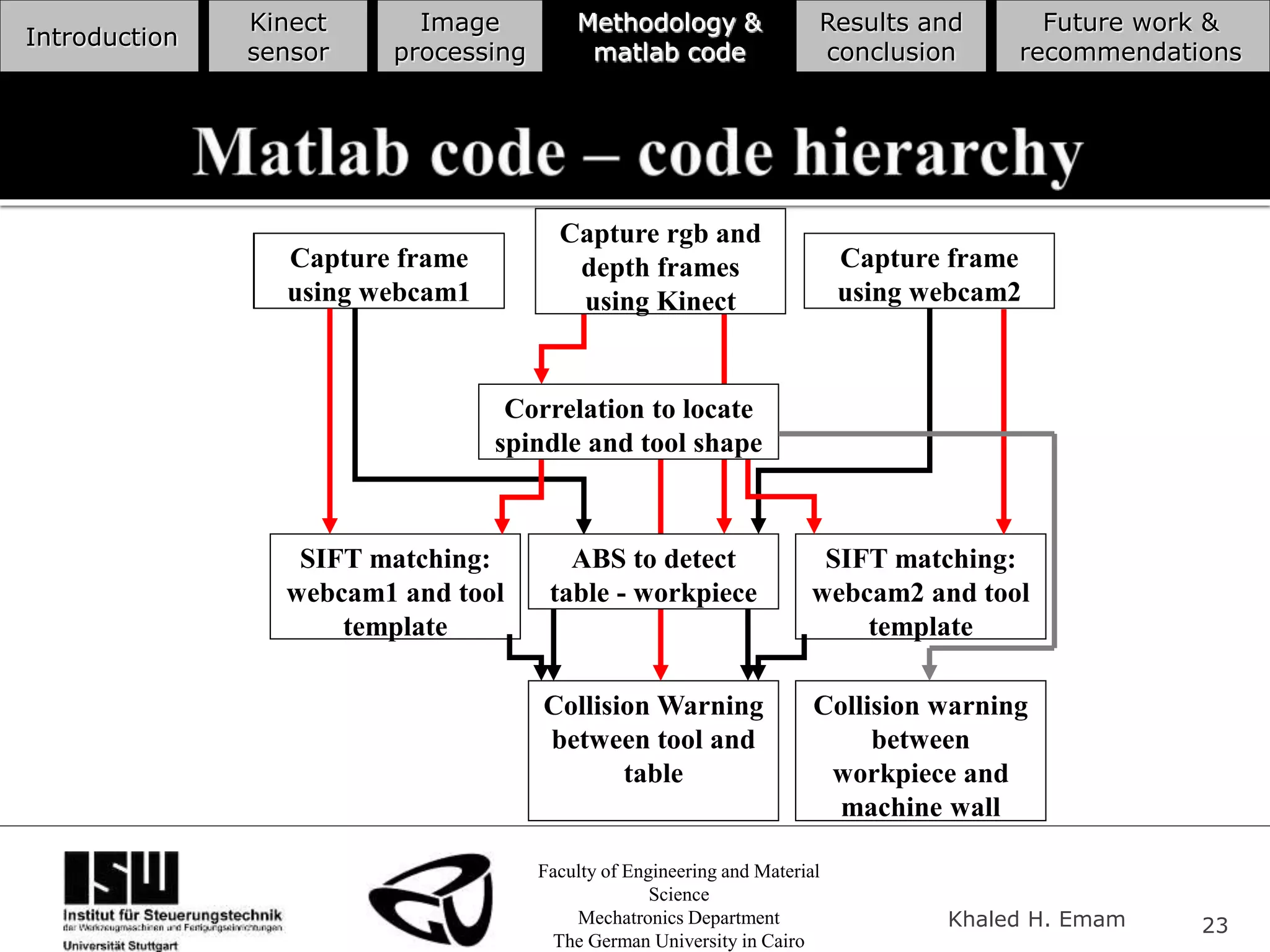

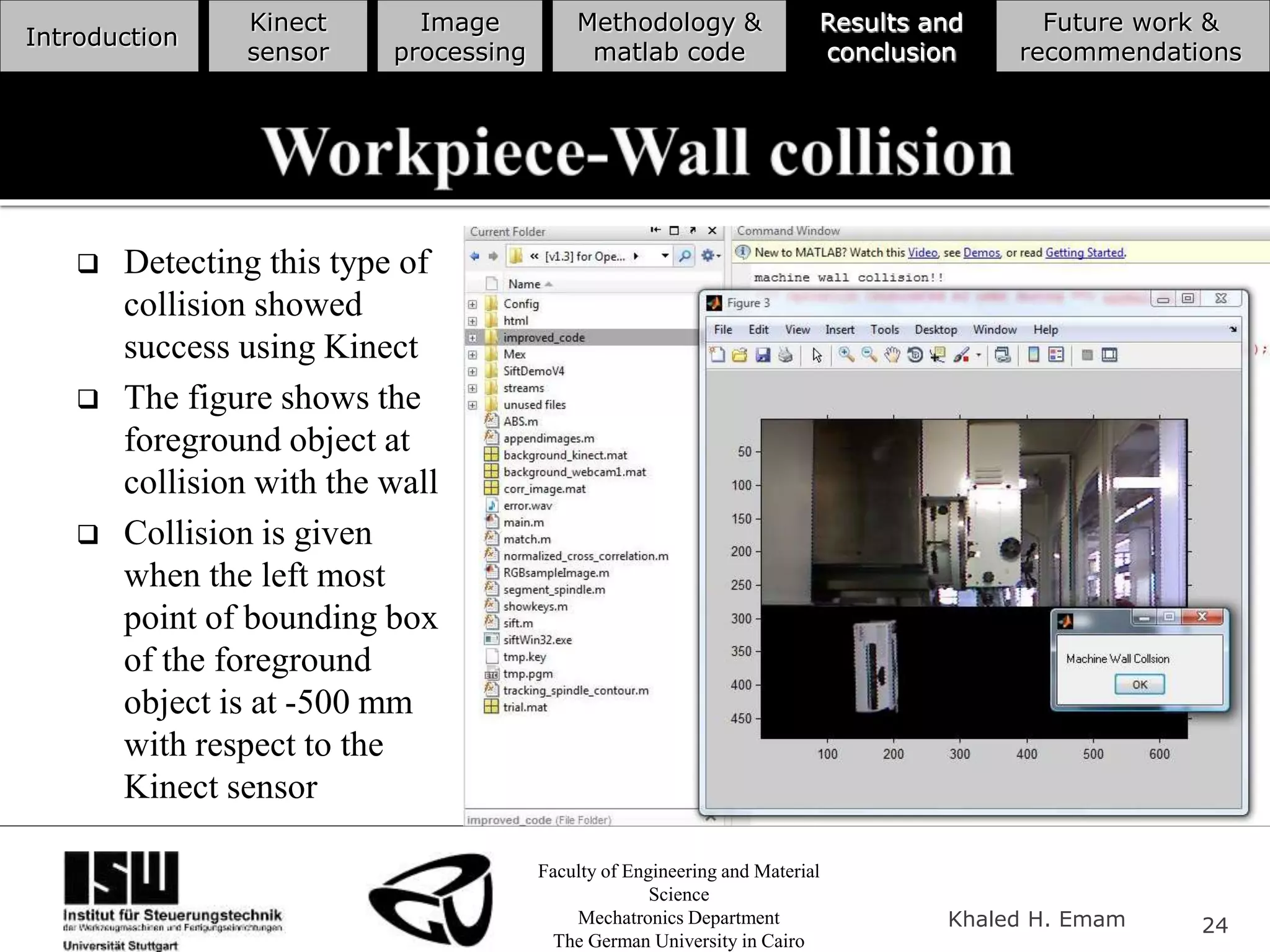

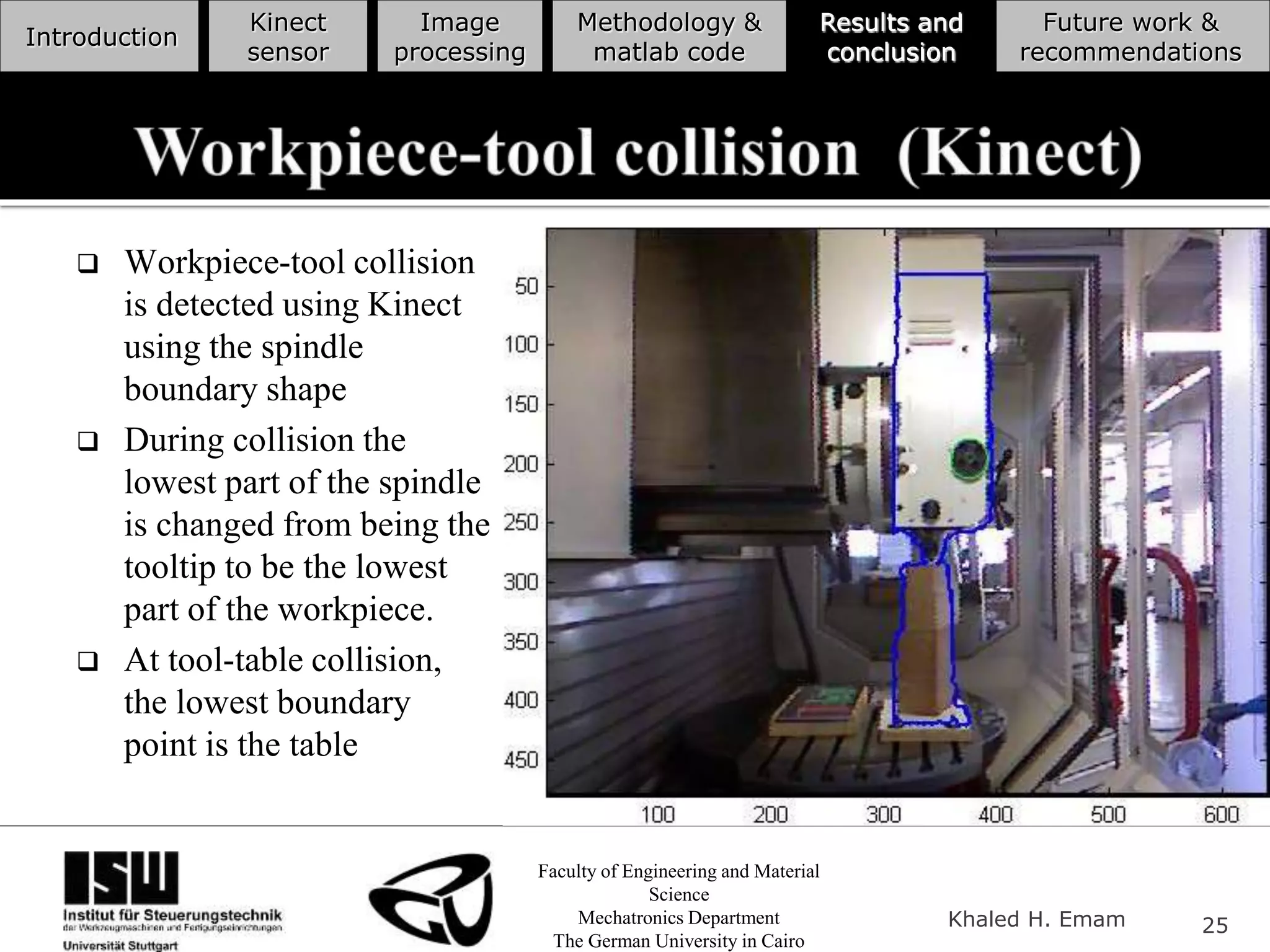

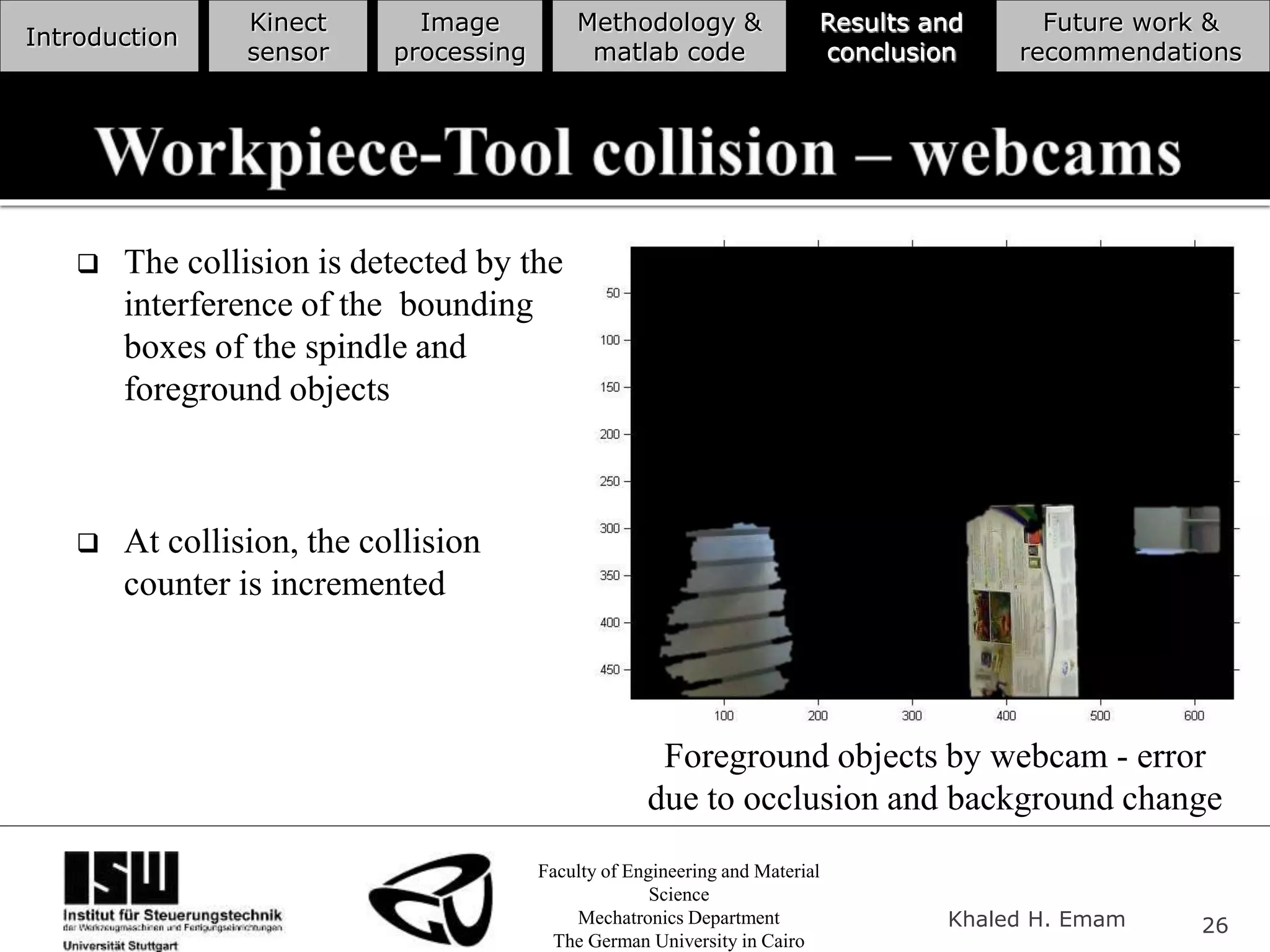

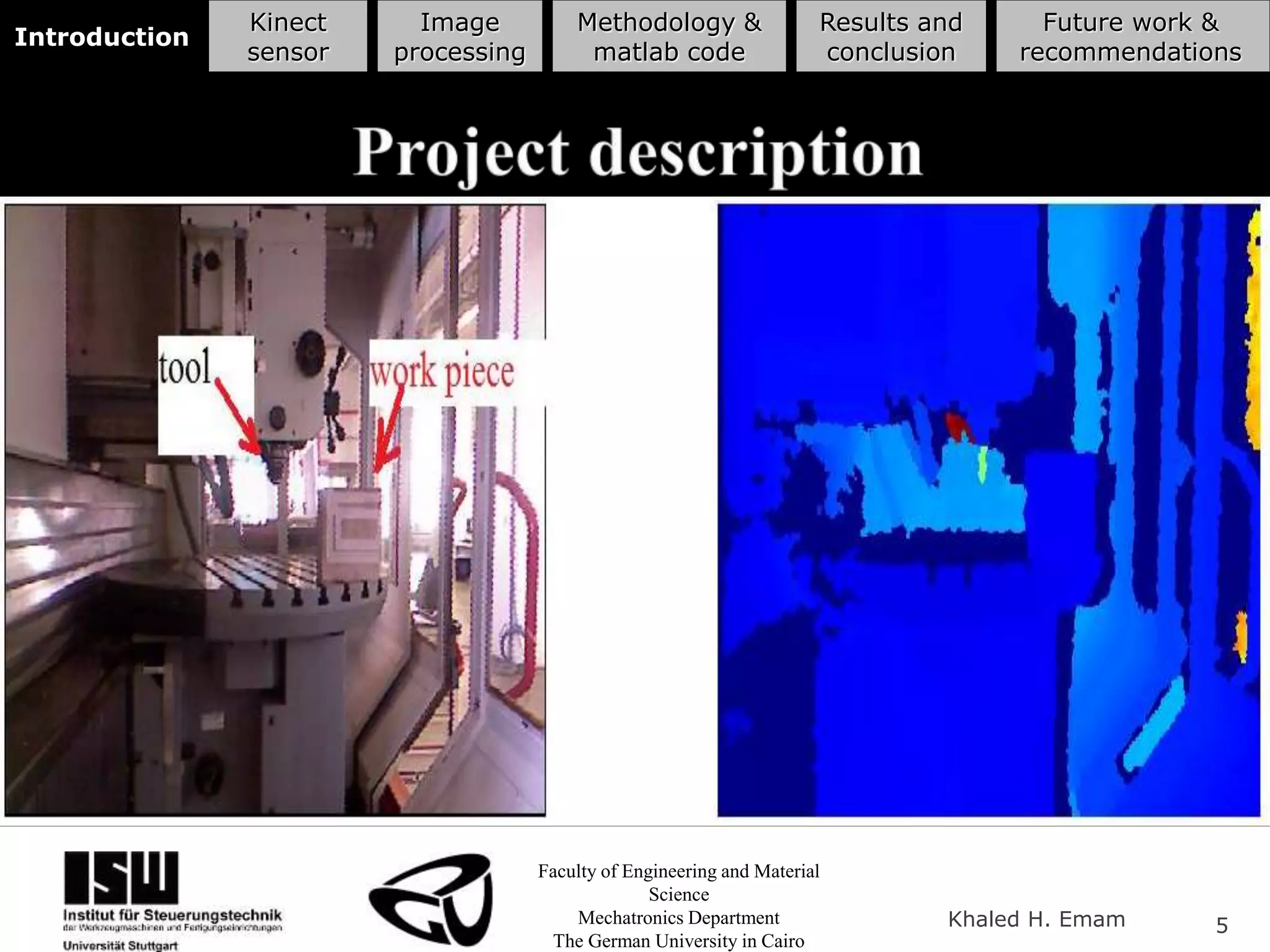

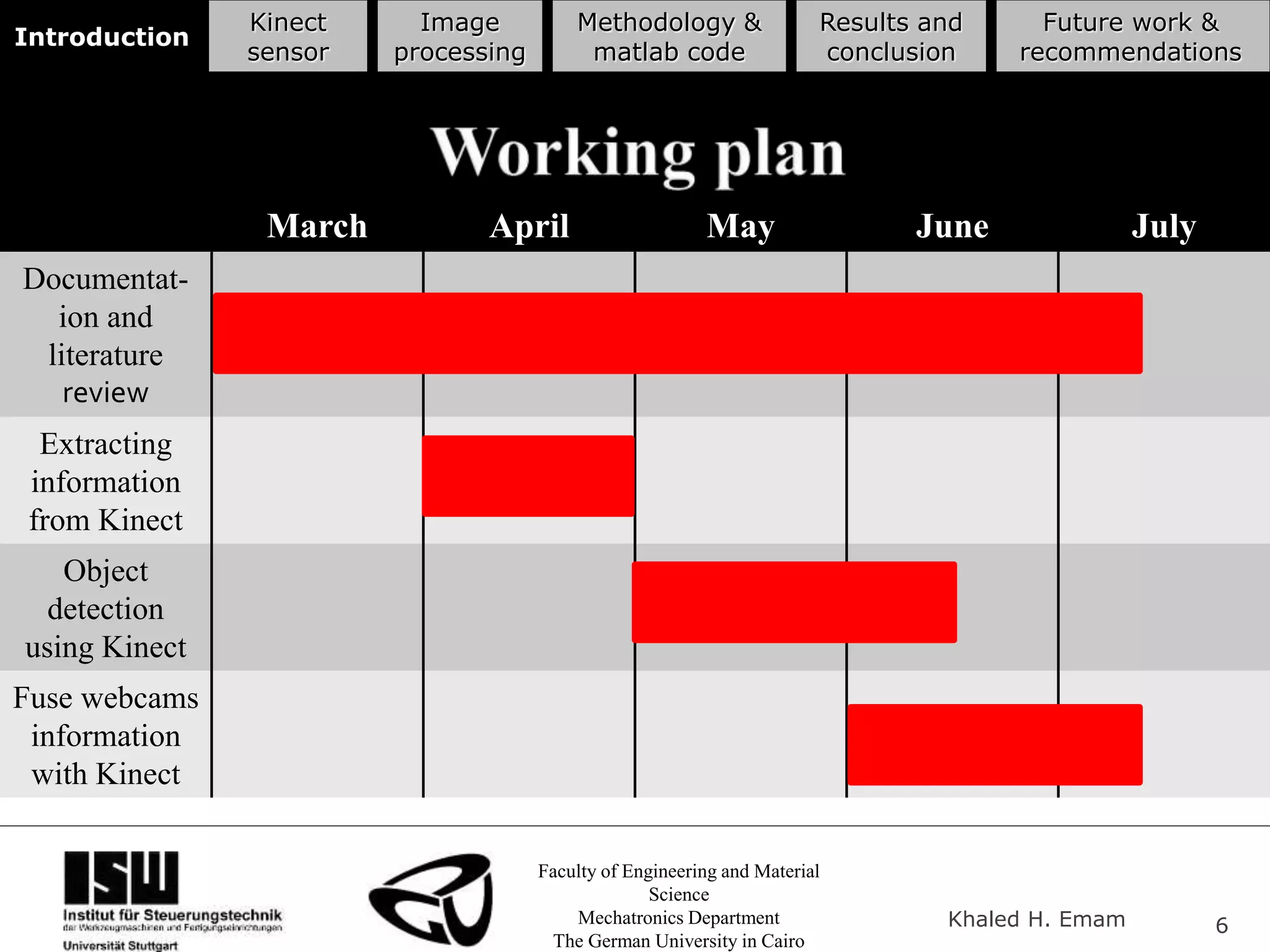

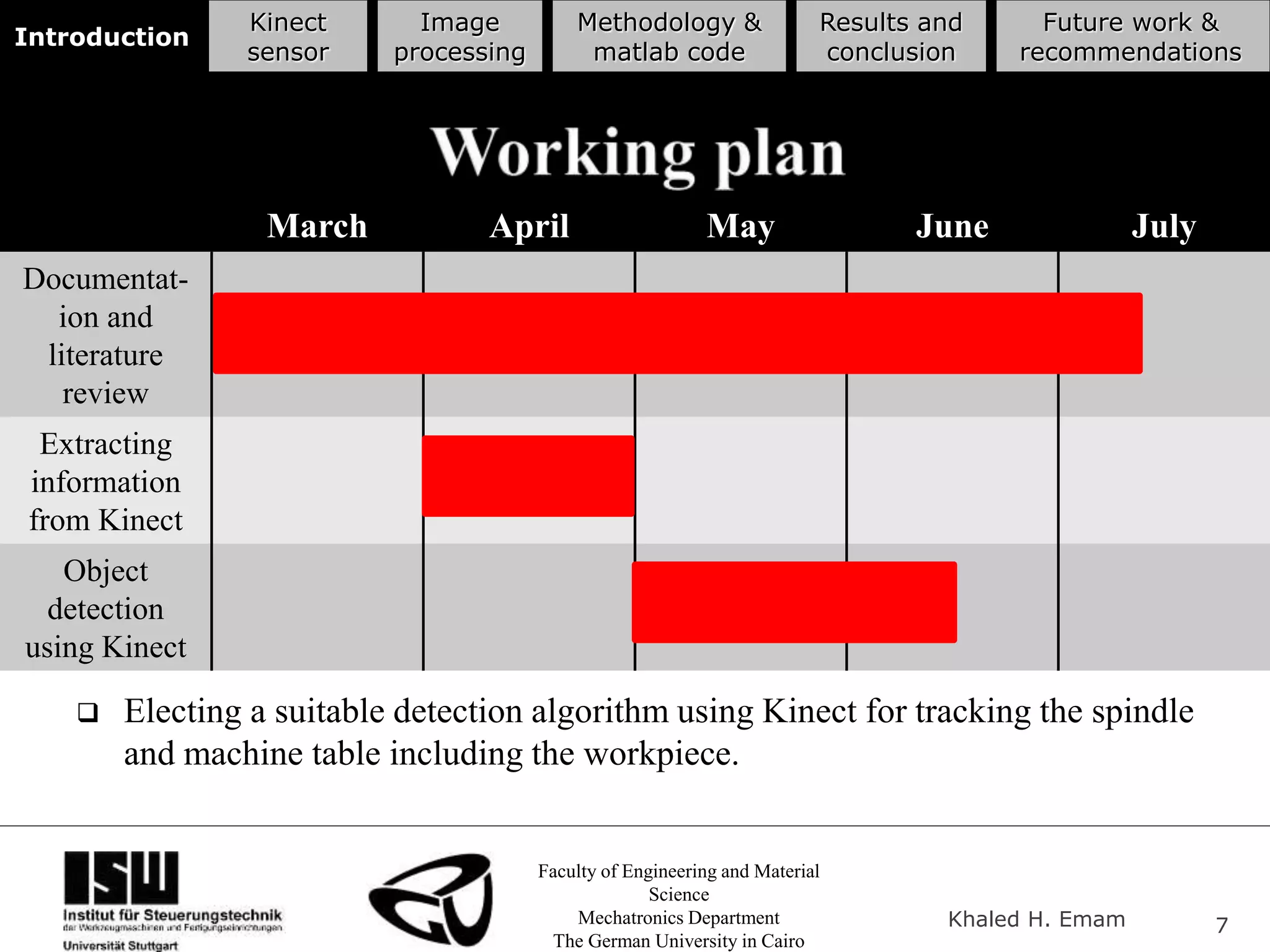

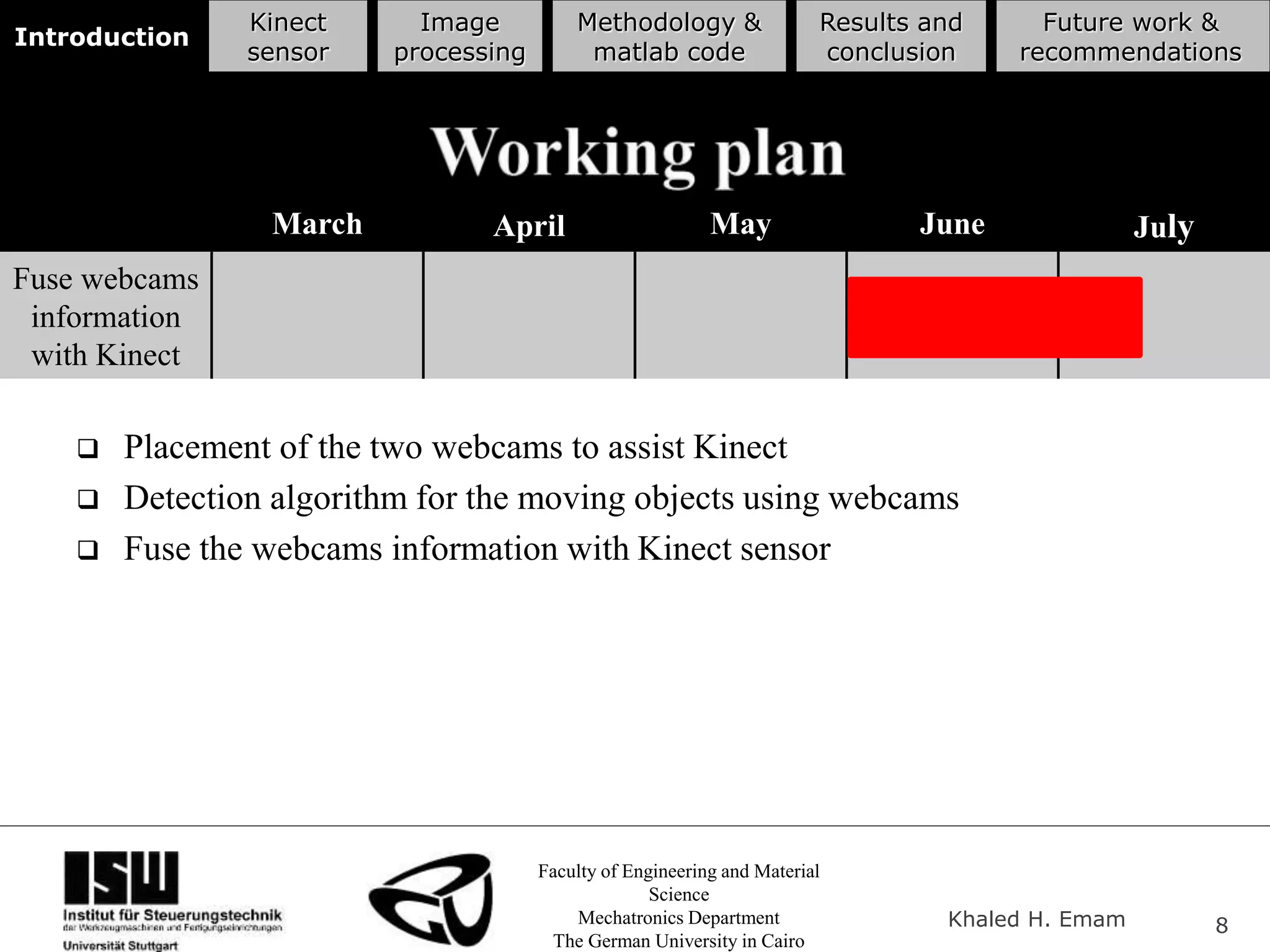

This document discusses collision avoidance in CNC machines using multiple sensors. It proposes detecting collisions between the cutting tool and workpiece using a Kinect sensor and two webcams through image processing techniques in MATLAB. The methodology involves extracting depth maps from Kinect to detect the spindle and workpiece, and using SIFT and normalized cross-correlation on webcam images to detect the cutting tool. Adaptive background subtraction will be used to isolate foreground objects. Detected objects across sensors will be fused to determine if a collision has occurred.

![Faculty of Engineering and Material

Science

Mechatronics Department

The German University in Cairo

Khaled H. Emam 10

Introduction

Kinect

sensor

Image

processing

Methodology &

matlab code

Results and

conclusion

Future work &

recommendations

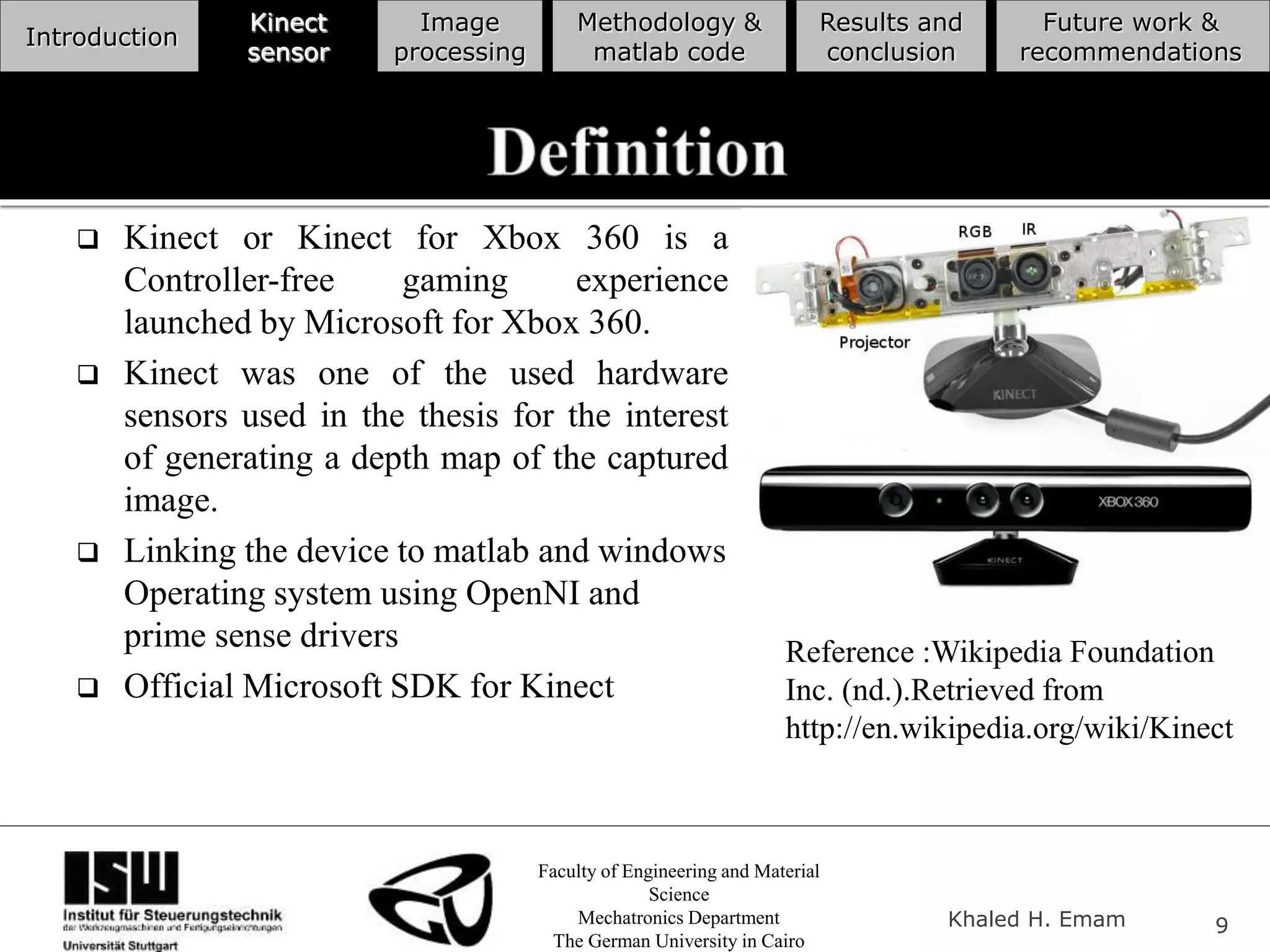

Converting from u[pixels],v[pixels],Z[mm] coordinates to

X[mm],Y[mm],Z[mm] Cartesian coordinates

Segmentation of objects using depth map](https://image.slidesharecdn.com/15e709f0-d40f-4f53-a644-e3ed060d9494-160216095540/75/Presentation2-10-2048.jpg)