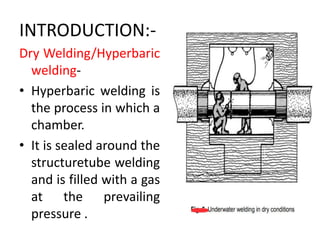

1) Dry welding, also known as hyperbaric welding, is a process where welding is performed underwater inside a pressurized chamber filled with gas.

2) The first underwater welding was introduced by the British Admiralty in docks, and specialized underwater welding electrodes were later developed in the 1940s in Holland. Standard underwater welding procedures were established by the American Welding Society in the 1970s.

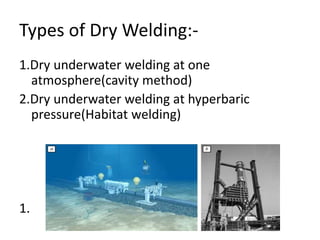

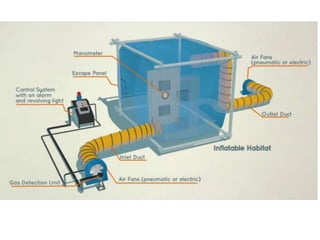

3) There are two main types of dry welding: cavity welding performed at one atmosphere, and habitat welding performed at hyperbaric pressure inside pressurized mini or large habitats on job sites. Automation and robots like THOR have improved the efficiency and safety of underwater welding.