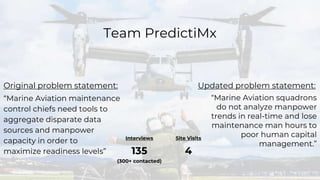

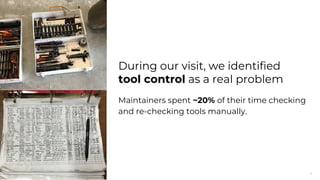

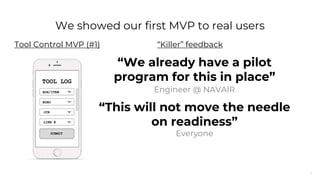

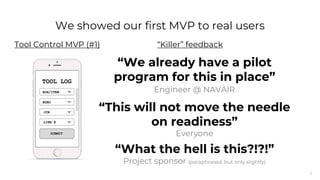

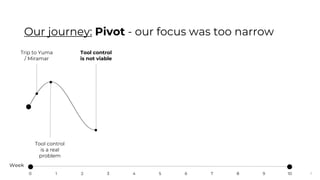

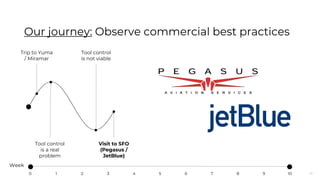

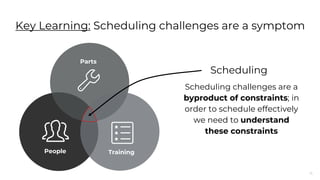

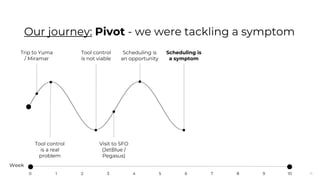

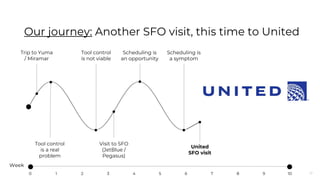

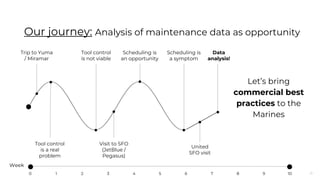

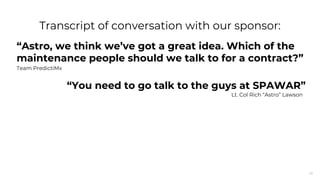

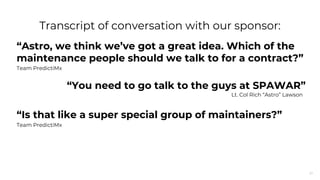

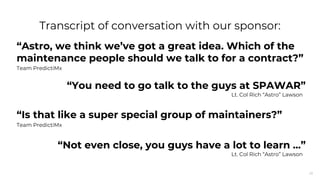

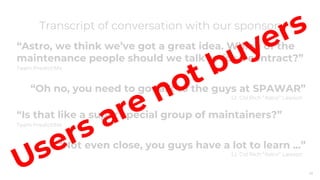

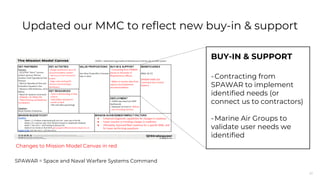

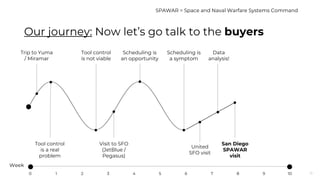

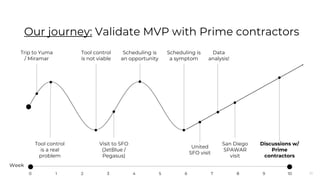

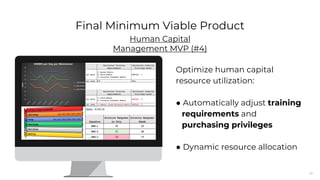

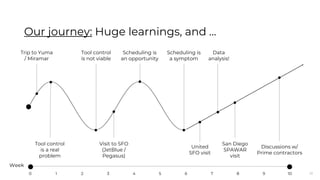

The document discusses the challenges faced by Marine aviation maintenance control chiefs in improving readiness levels due to inefficient manpower management and scheduling practices. Through various site visits and user feedback, the team pivoted from initial tool control solutions to focusing on dynamic scheduling and trend analysis to better utilize resources and predict maintenance needs. The findings highlight the need for the Marine Corps to adopt more advanced data analytics practices, similar to those in commercial aviation.