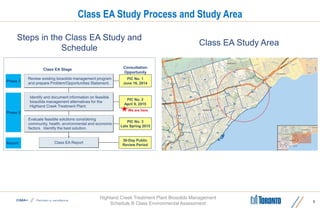

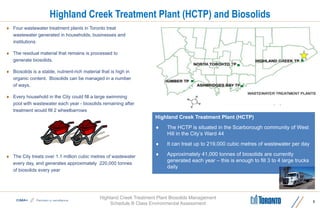

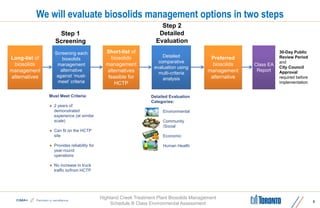

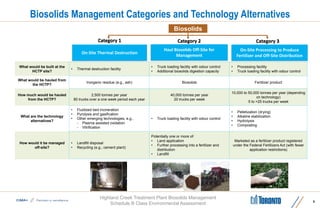

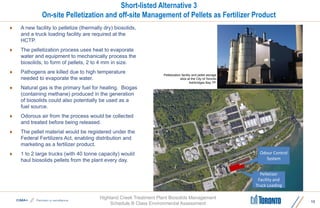

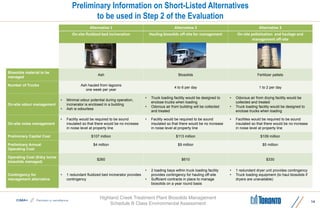

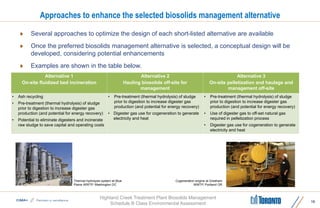

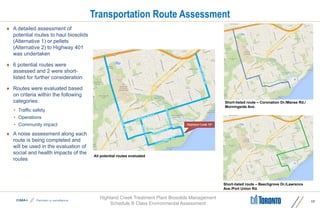

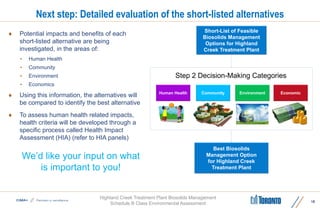

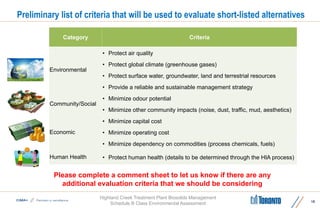

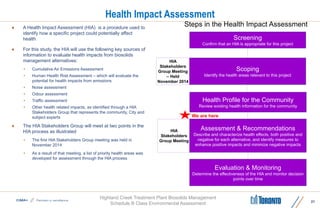

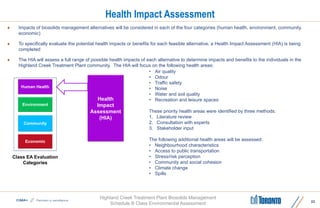

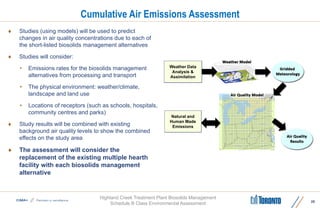

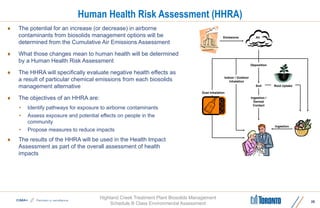

The document discusses a public information centre for a biosolids management environmental assessment at the Highland Creek Treatment Plant. It provides background on the current biosolids management process, which involves incineration. The study is evaluating alternative management options, including on-site fluidized bed incineration, hauling biosolids off-site, and on-site pelletization. Three alternatives were shortlisted based on criteria such as reliability and space. The evaluation methodology and preliminary shortlisted alternatives are described. Input from the public will help select the preferred option.