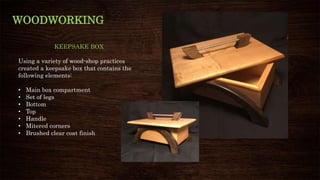

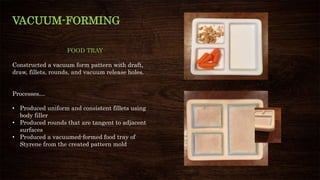

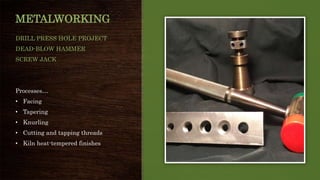

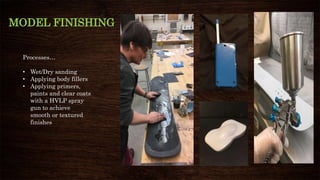

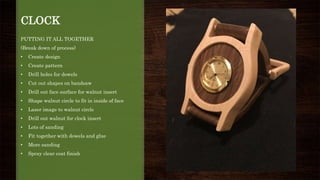

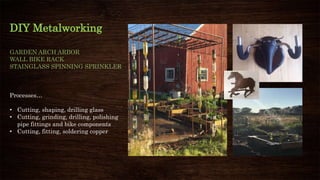

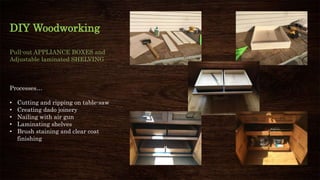

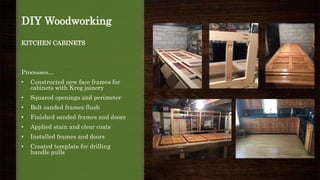

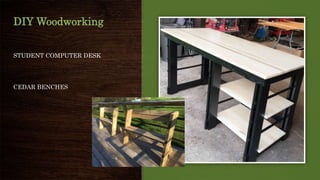

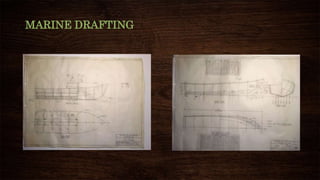

The document summarizes the Prototyping & Design program at Northeast Wisconsin Technical College. The program trains students to build 3D prototypes through skills like hand fabrication, painting, 3D software, CNC machining, model making, and welding. Students learn to develop plans from 2D to 3D, problem solve, create CAD drawings, use CNC machines, construct models, apply finishes, estimate costs, and operate tools safely. Examples are provided of projects involving laser etching, woodworking, vacuum forming, CNC milling, metalworking, model finishing, and computer-aided drafting.