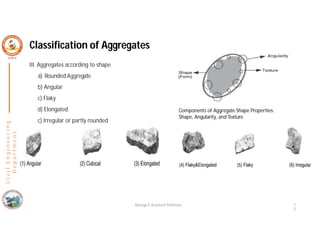

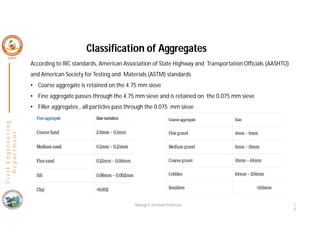

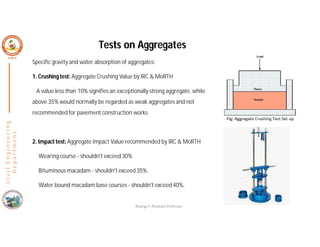

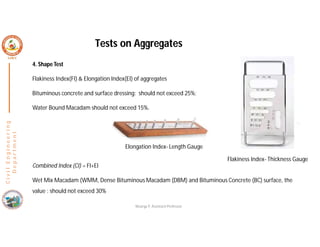

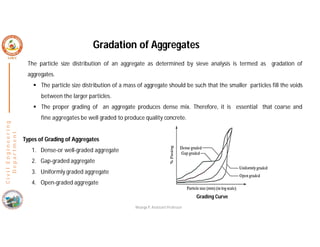

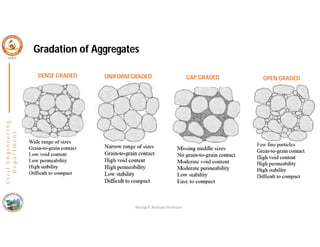

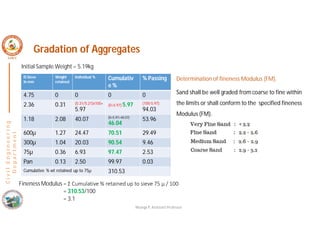

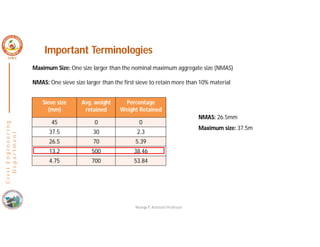

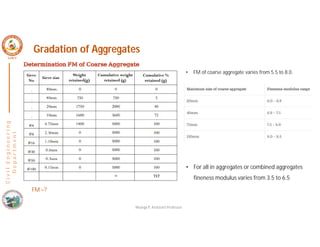

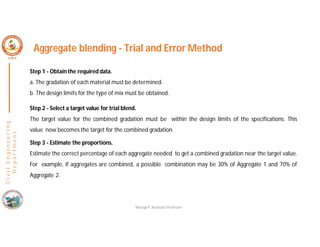

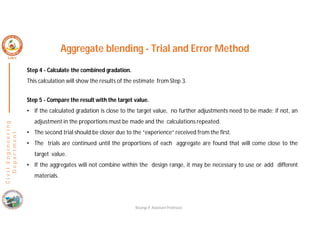

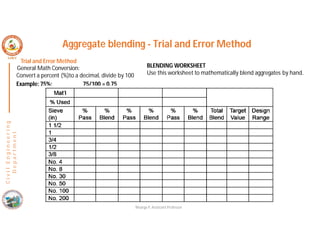

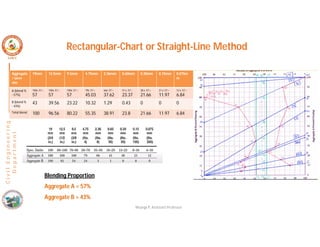

This document discusses aggregates used in pavement materials. It defines aggregates and their classification according to origin, size, and shape. Natural aggregates come from rocks and are classified as igneous, sedimentary, or metamorphic. Tests are conducted to determine aggregates' properties, including crushing strength, impact resistance, abrasion resistance, shape, density, and adhesion to binding materials like bitumen. Proper aggregate grading involves a mix of sizes that limits voids. Specifications provide limits for test results to ensure only suitable aggregates are used in pavement construction.