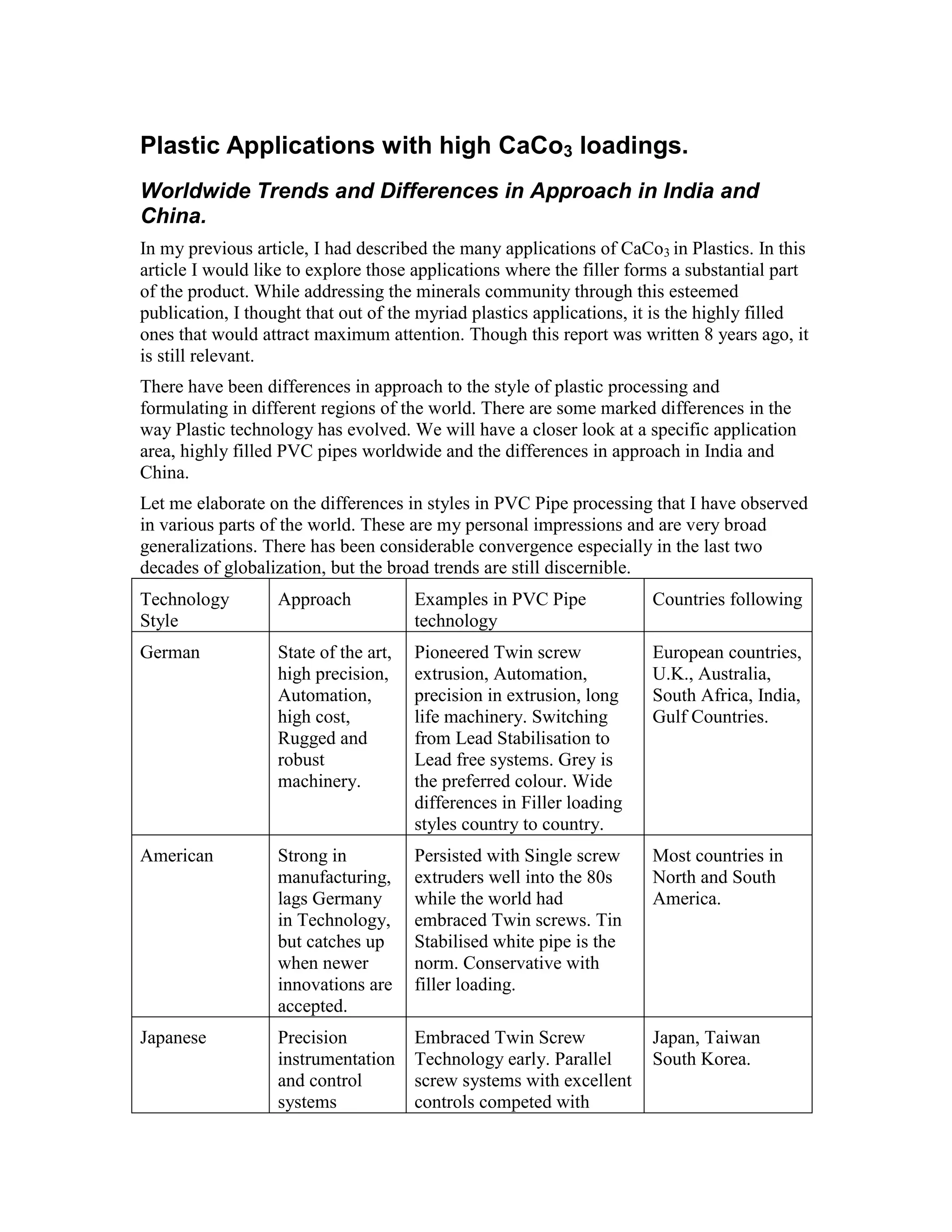

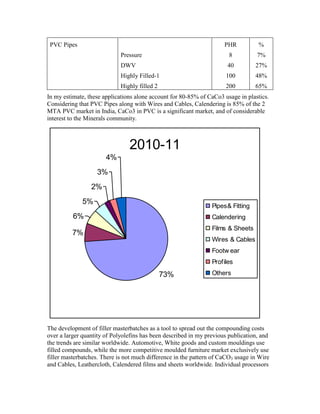

The document discusses differences in approaches to highly filled plastic applications between India and China, focusing on PVC pipes. India uses high calcium carbonate (CaCo3) fillers without impact modifiers or flow promoters, leading to breakage issues. China uses locally developed chlorinated polyethylene (CPE) and acrylic (ACR) additives to boost CaCo3 levels up to 200phr while maintaining performance. The document analyzes how additive selection impacts properties and processing of highly filled PVC pipes.