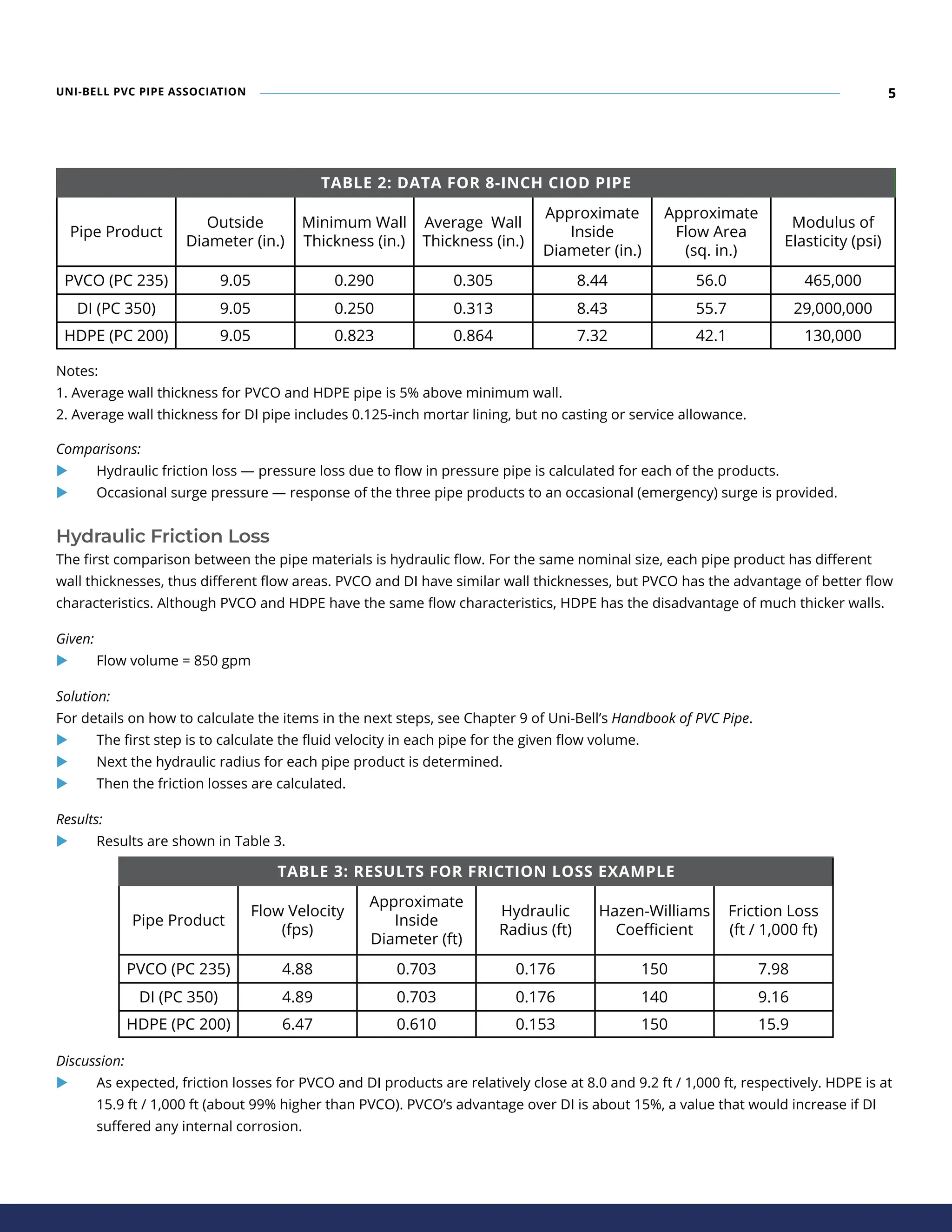

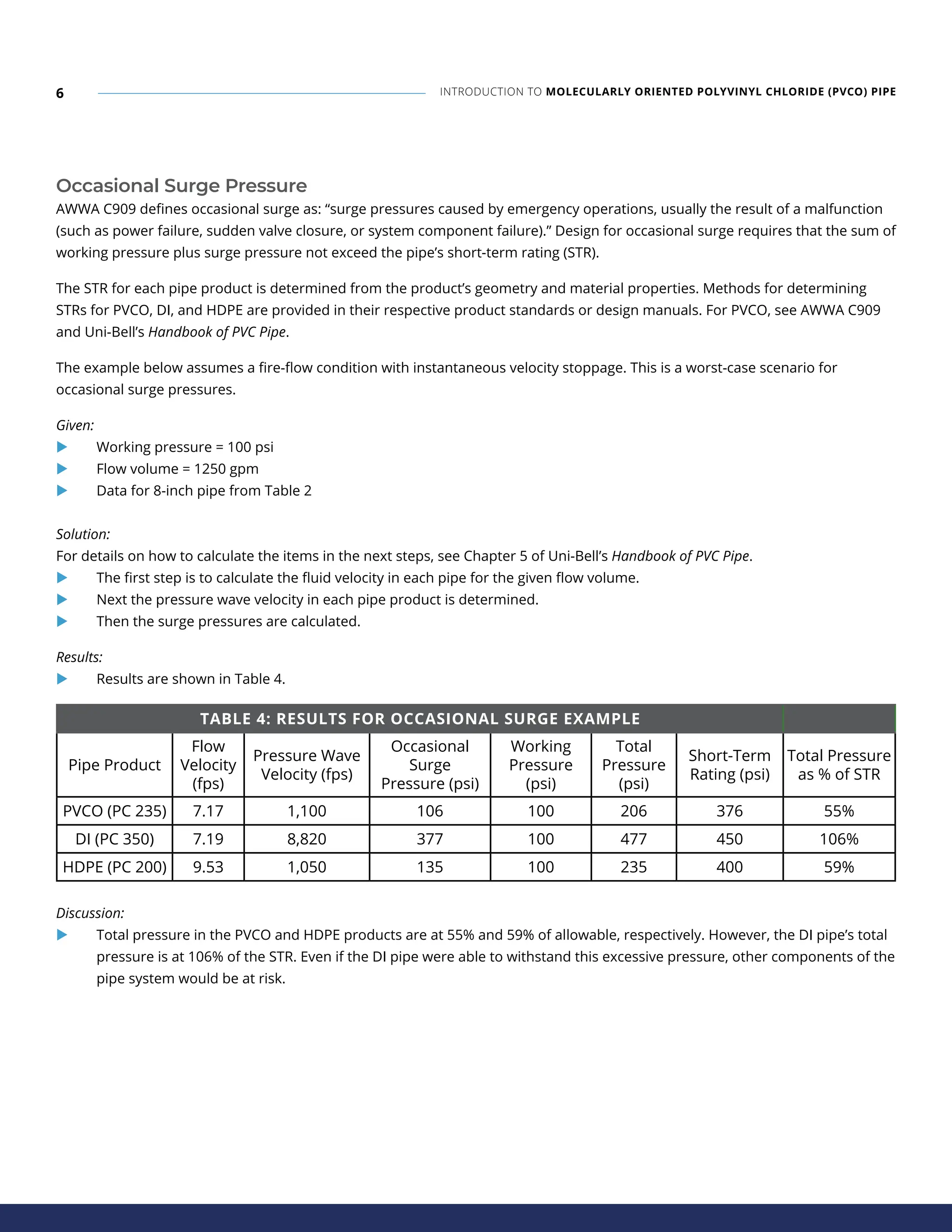

The document provides an overview of molecularly oriented polyvinyl chloride (PVCO) pipe, including its history, manufacturing processes, and installation considerations. Developed over four decades ago, PVCO offers enhanced mechanical strength compared to traditional PVC, making it suitable for various applications in water distribution systems. Key differences with ductile iron and HDPE pipes are highlighted, particularly in terms of weight, installation ease, and resistance to corrosion.