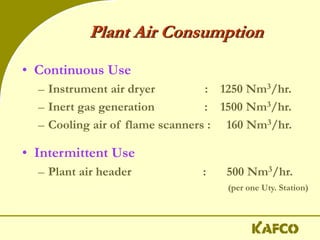

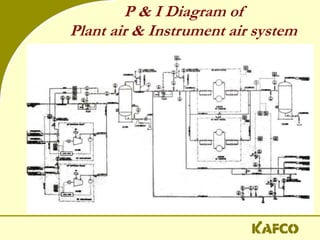

This document describes the operation and troubleshooting of a plant air and instrument air system. The system consists of two air compressors and dryers that compress and dry air. The dried air is supplied to various plant instruments and processes. In normal operation, compressed air is extracted from another compressor and fed to the air receiver. Startup and shutdown procedures are outlined. Common problems like power failures, cooling water issues, and compressor or dryer failures are addressed. Troubleshooting steps for each problem are provided.