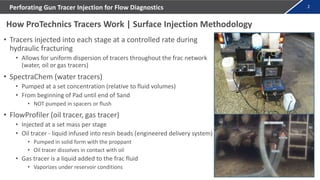

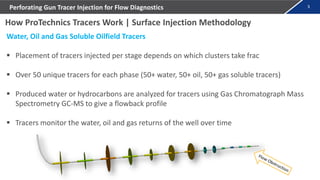

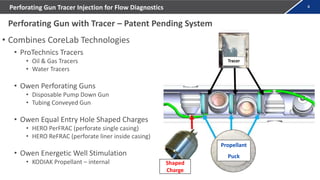

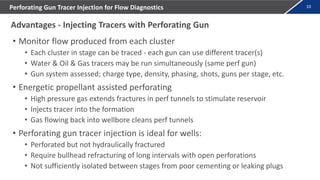

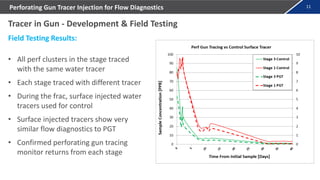

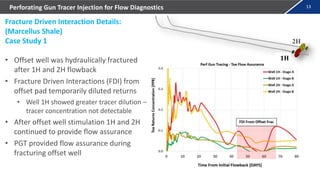

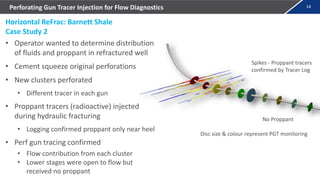

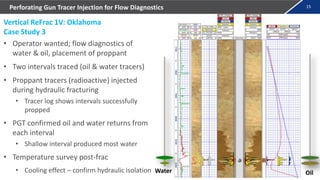

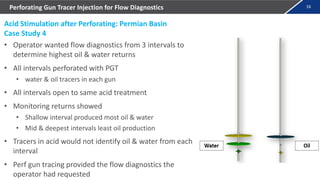

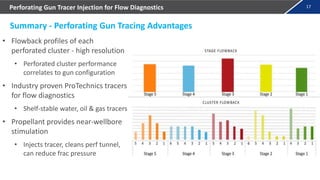

1) Perforating gun tracer injection allows operators to trace flowback from individual perforated clusters by injecting unique tracer materials into each perforating gun stage.

2) Tracers are then detected in produced fluids to generate high-resolution flowback profiles for each stage and assess perforating effectiveness.

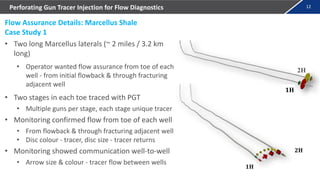

3) The technique is particularly useful for refracturing wells with long open perforation intervals or where isolation between stages is poor, and helps operators evaluate perforating performance, hydraulic fracturing results, and fluid returns from acid stimulations.