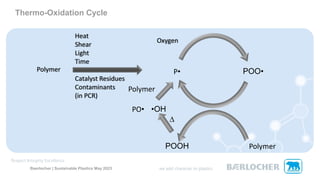

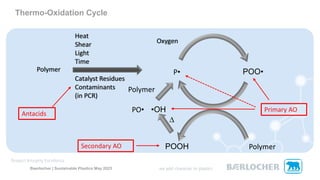

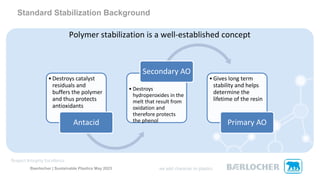

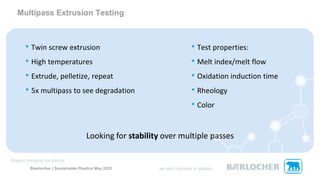

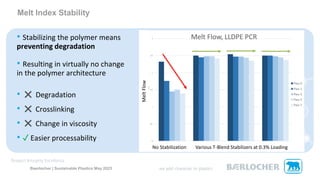

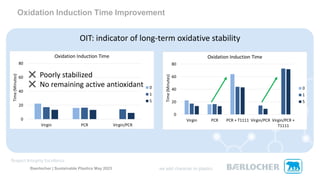

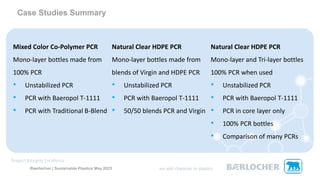

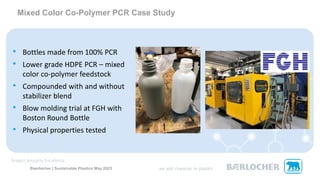

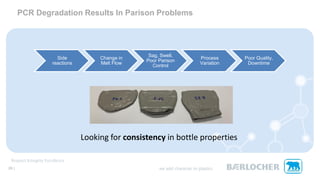

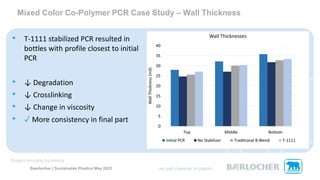

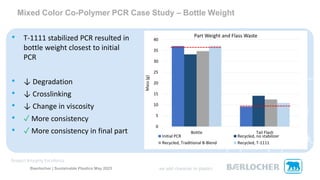

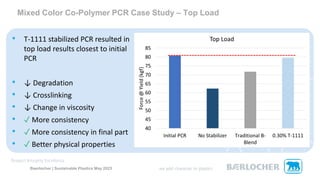

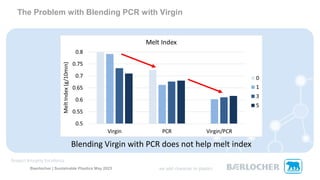

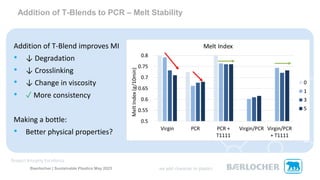

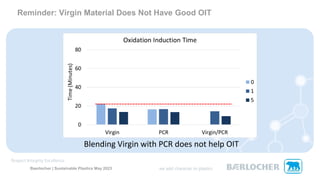

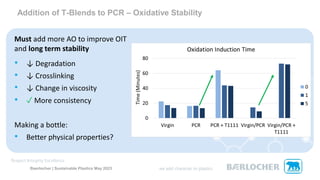

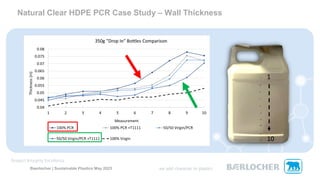

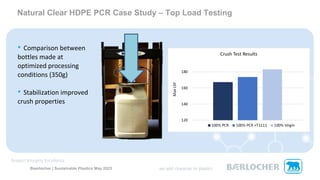

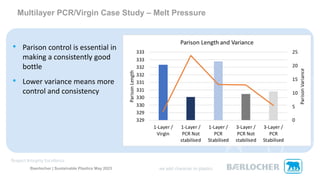

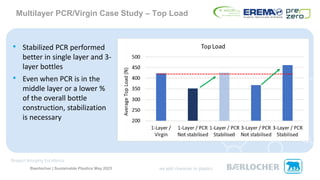

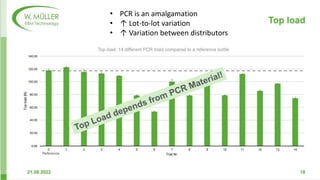

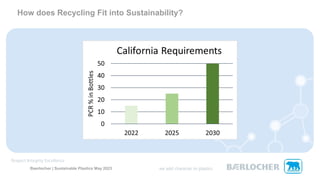

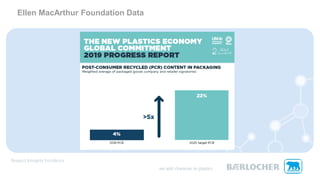

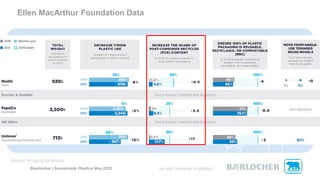

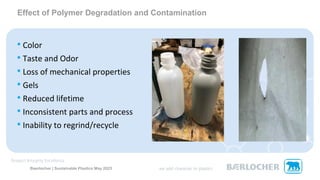

The document summarizes a presentation on supporting sustainable plastics through additives. It discusses challenges with recycling goals versus reality, how polymer properties deteriorate during recycling without stabilization, and case studies showing how Baerlocher's RST stabilizer blends can improve the stability and properties of post-consumer recycled resins during processing and in final products like blow molded bottles. The studies found stabilization reduced degradation, crosslinking, and variability to provide more consistent processing and strengthened final part properties.

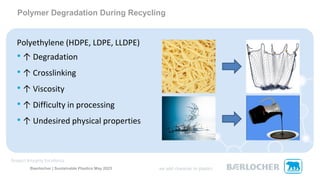

![Why do polyolefin properties deteriorate during recycling?

• Most polyolefin grades are made for short lived consumer applications and are

not stabilized for recycling

• Additional AO is needed to protect the inherent properties of the polymer during

the recycling step – Damage done to the polymer at this stage cannot be

corrected later!

Source: Fraunhofer Institute for Structural Durability and System Reliability LBF: www.lbf.fraunhofer.de

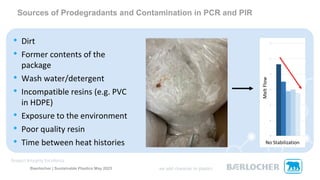

Property Virgin Polyolefin Recyclate Consequences

Carbonyl groups [mmol/kg] <2 10 - >100 Initiator sites for accelerated oxidation and photo oxidation

Acidic groups [mmol/kg] <1 10 - 100 Accelerated oxidative degradation

Double bonds [mmol/kg] 10 5 - 200 Accelerated oxidative degradation, higher sensitivity for cross

linking (gel formation) in PE, discolouration from conjugated

double bonds

Metal impurities [ppm] <50 50 - >2000 Oxidation catalysts

Baerlocher | Sustainable Plastics May 2023](https://image.slidesharecdn.com/elaynasimmons-230516042106-6d7a36e5/85/SUPPORTING-SUSTAINABLE-PLASTICS-THROUGH-ADDITIVES-16-320.jpg)