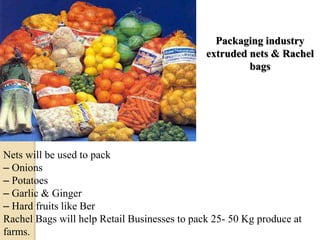

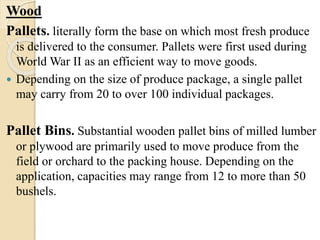

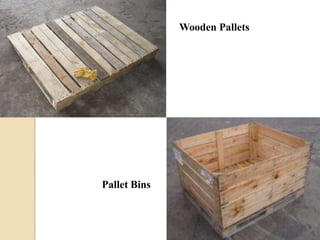

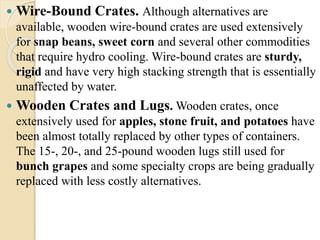

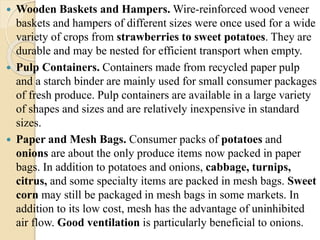

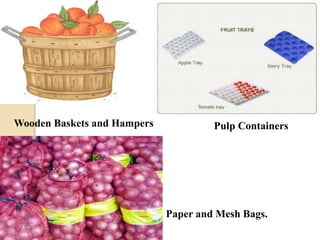

The document outlines the importance of packaging in the produce industry, detailing types of packaging materials and processes used for fruits and vegetables. It highlights the various functions of packaging, such as protection, presentation, and convenience, along with the need for materials that are safe and efficient. Additionally, it discusses specific packaging methods for apples, emphasizing the importance of maintaining freshness and quality from packing to consumer delivery.