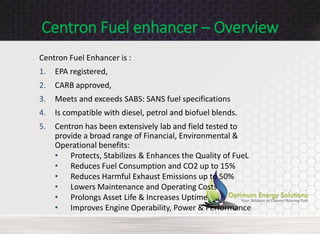

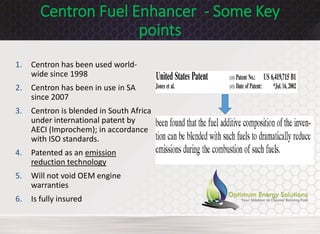

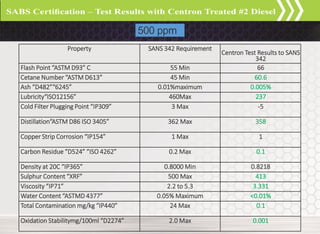

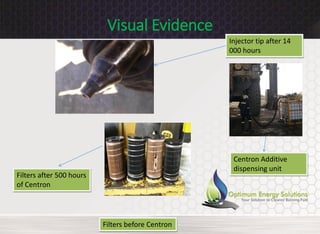

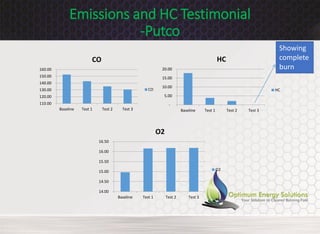

Optimum Energy provides fuel additives and hydrogen generation systems to reduce harmful emissions and improve fuel efficiency. Their Centron fuel additive has been tested extensively and is EPA registered, CARB approved, and SABS compliant. It is designed to reduce fuel consumption by up to 15%, cut emissions by up to 50%, and lower operating costs while extending engine life. Testing on vehicles and mining/transport equipment demonstrated significant improvements to fuel economy, emissions reductions, and equipment uptime without any vehicle modifications required. Optimum Energy proposes partnering with the City of Cape Town on a trial program to validate these benefits.