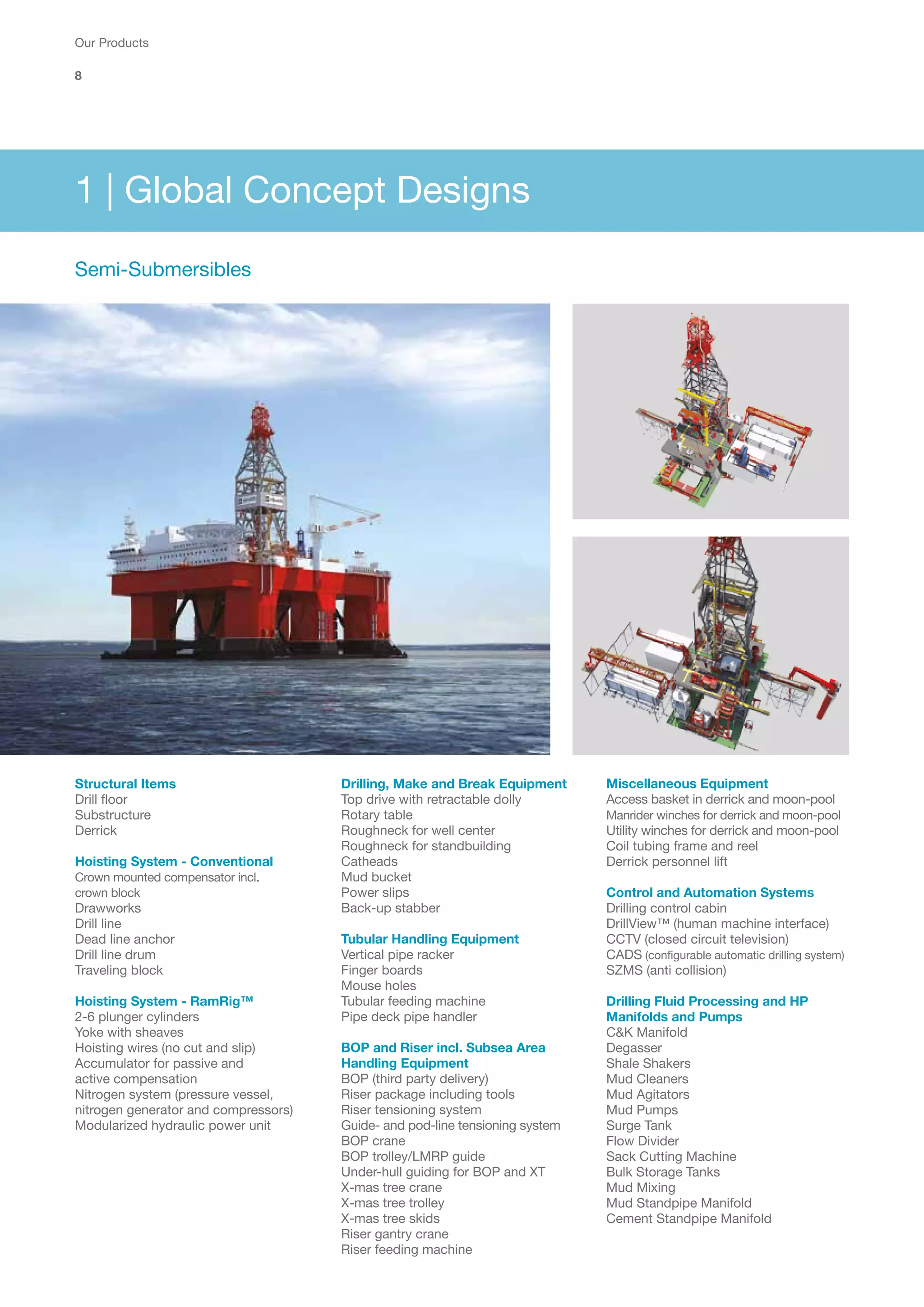

This document provides an overview of MHWirth's products for drilling solutions. It discusses their global concept designs for drillships, jackups, platform rigs, and semi-submersibles. It also covers their structures and traveling equipment including their RamRig technology, derricks and masts, and traveling equipment. Finally, it outlines their drilling, make and break equipment such as top drives, rotary tables, roughnecks, slips, drawworks, back-up stabbers, catheads, and mud buckets. The document aims to showcase MHWirth's full range of offshore drilling equipment and solutions.