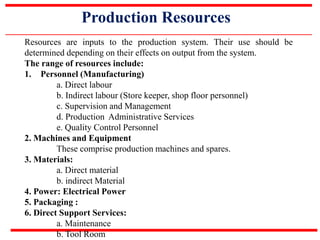

This document discusses organization planning techniques including organization analysis and design. It describes the principal components of an organization as management systems including the planning, control, communication, and evaluation systems. It also outlines the basic parts of an organization such as the operating core, strategic apex, middle line, technostructure, and support staff. Finally, it covers topics like production resources, planning, control, scheduling, and sequencing.