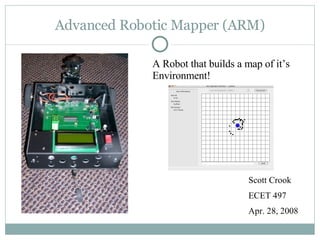

The document summarizes the Advanced Robotic Mapper (ARM) project. The ARM is a robot that can build a map of its environment. It includes components for position and orientation tracking, mapping sensors, a main controller and LCD, and software for mapping, navigation and user interfacing. Initial tests showed the robot could accurately map a surface 4+ feet away and travel a square path, but position tracking degraded over time. The compass was unstable when motors operated due to magnetic interference.