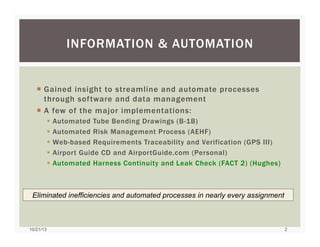

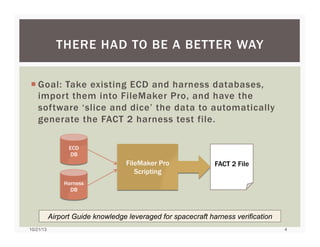

Michael Forte automated several processes at Hughes Space and Communications to streamline workflows and eliminate inefficiencies. This included automating the generation of continuity and leak check files for spacecraft harnesses, which reduced the task time from one month to just ten minutes while eliminating errors. The automation saved $250,000 annually and earned Forte several awards. He leveraged his problem-solving skills and an entrepreneurial mindset to find technological solutions that were faster, better, and cheaper than traditional manual processes.

![HEADER (STL ODIN BUS MODULE CONTINUITY AND LEAK TESTS, ,B5.PAR,STD.FMT,)

WRITE(WHEN=ALWAYS,DEST=CRT,LPT;ACTION=WAIT

;TEXT=

STL ODIN BUS MODULE HARNESS SHAKEDOWN

RESISTANCE AND DIODE TEST PROGRAM

TEST SPEC NO. TP 80615-H04-651 REV. -

WRITE(WHEN=ALWAYS; DEST=CRT

HARNESS ASSY. NO. 8026900-100 / 8027313

WIRE LIST NO. 8026900-300 REV. (-) EO'S: NONE

8027314 REV. (-) EO'S: EO-01

DATABASE DATE: 10-12-01

(321) DATABASE DATE: 09-28-01

TEST SPEC. NO. TP

CREATED BY: SEAN PHANG ON 11-25-01

;)

CONT(IDC;F00000[GROUND]T36944[4001P004-035]T36945[4001P004-036])

CONT(T36946[4001P004-037]T37850[4003P004-035]T37851[4003P004-036])

CONT(T37852[4003P004-037]T37944[4002P004-035]T37945[4002P004-036])

CONT(T37946[4002P004-037]T38619[1000J001-010]T38643[1000J001-034])

CONT(T38662[1000J001-053]T38663[1000J001-054]T38664[1000J001-055])

CONT(T38665[1000J001-056]T38666[1000J001-057]T38667[1000J001-058])

CONT(T38668[1000J001-059]T38669[1000J001-060]T43442[4003P001-033])

CONT(T43443[4003P001-034]T43444[4003P001-035]T43445[4003P001-036])

LEAK(VDC;F36011[9031P001-00B])

LEAK(VDC;F36012[9031P001-00C])

LEAK(VDC;F36015[9031P001-00F])

LEAK(VDC;F36017[9042P001-00B])

LEAK(VDC;F36018[9042P001-00C])

LEAK(VDC;F36021[9042P001-00F])

SAMPLE FACT 2 FILE

Sample final output of FACT 2 File for harness shakedown

FACT 2 file generated with 20k lines , 0 errors, 10 minutes

10/21/13 7](https://image.slidesharecdn.com/4380f2e1-dd8d-4e05-93dd-fe7f58779b17-160714040551/85/FACT-2-Case-Study-Presentation-7-320.jpg)