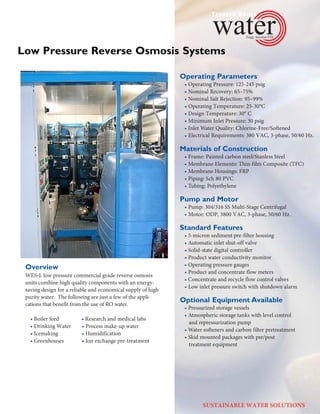

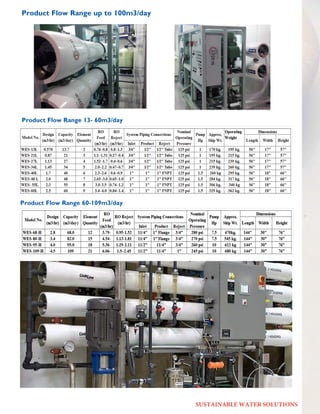

This document summarizes a reverse osmosis water purification system. It describes the system's operating parameters, materials of construction, standard features, and optional equipment. The system uses thin-film composite membrane elements and can produce up to 100 cubic meters of purified water per day. It operates at pressures between 125-250 pounds per square inch and removes 95-99% of salt from the water.