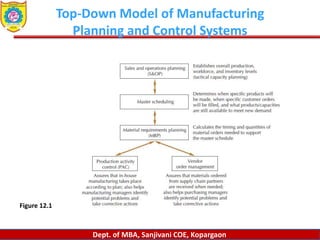

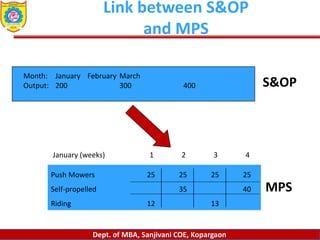

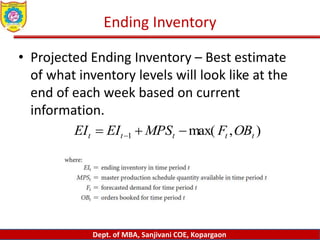

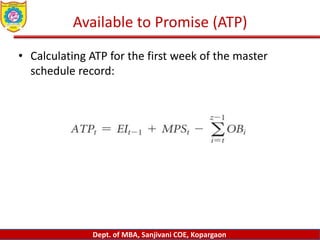

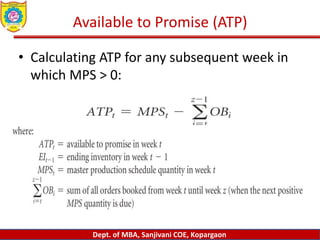

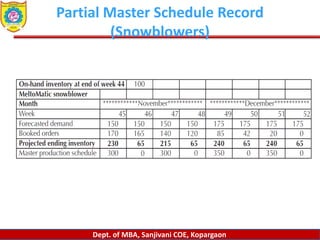

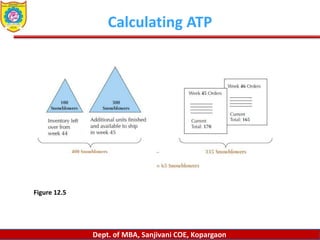

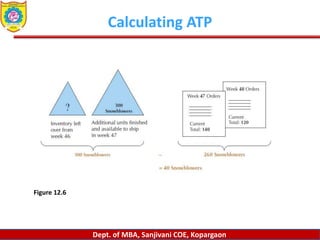

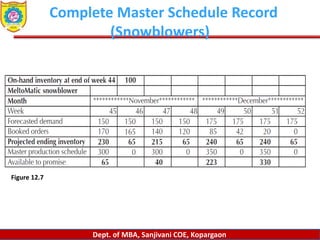

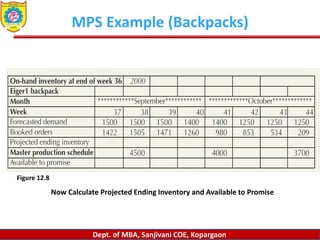

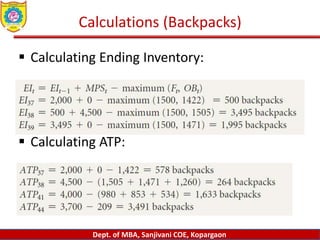

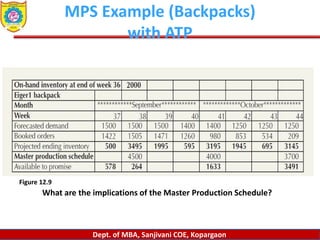

The document discusses master production scheduling (MPS) as a critical process in operations management, detailing its role in synchronizing production output with customer orders and market demand. It explains how MPS serves as a bridge between sales and operations planning (S&OP) and highlights key elements such as forecasted demand, booked orders, and available-to-promise (ATP) quantities. Additionally, the document includes graphical representations and examples of calculations related to MPS, illustrating how to determine projected inventory and ATP for specific products.