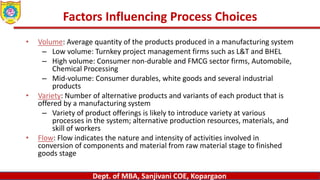

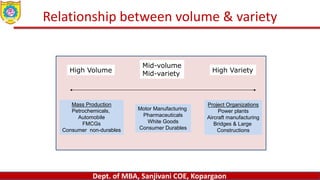

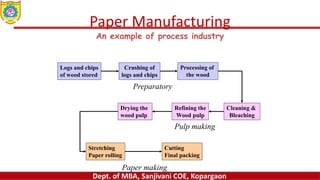

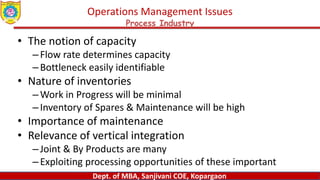

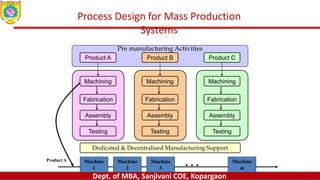

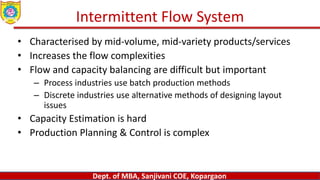

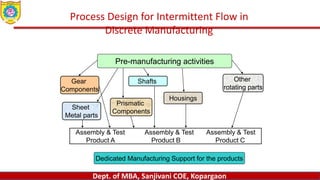

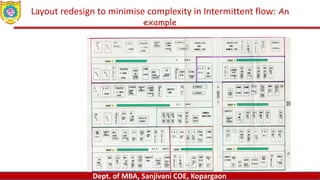

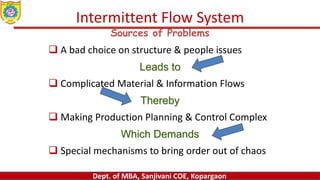

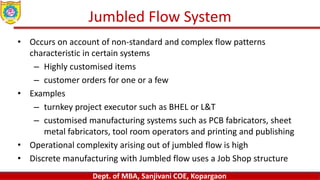

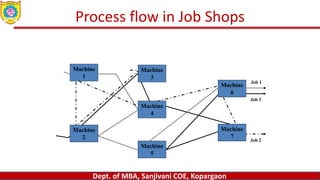

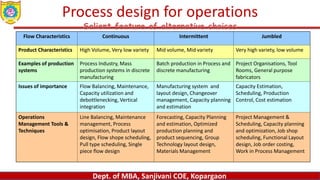

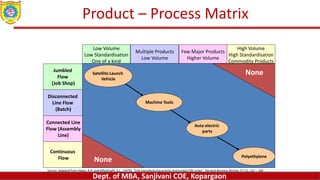

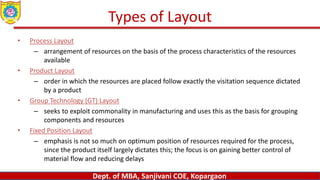

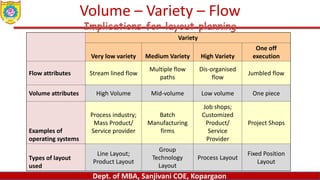

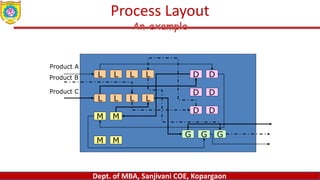

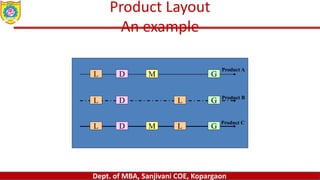

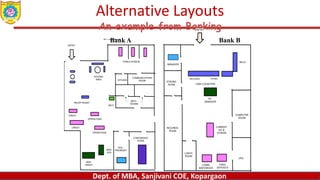

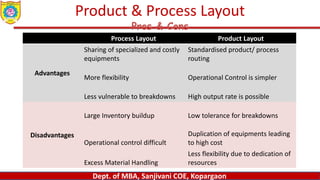

This document discusses various types of operations processes and layouts. It begins by describing factors that influence process choices such as volume, variety, and flow. The three types of flows are defined as continuous, intermittent, and jumbled. Examples are given for each type of flow and industry. Process layouts, product layouts, group technology layouts, and fixed position layouts are also described along with their pros and cons. The relationship between volume, variety, and flow and appropriate layout choices is also discussed.