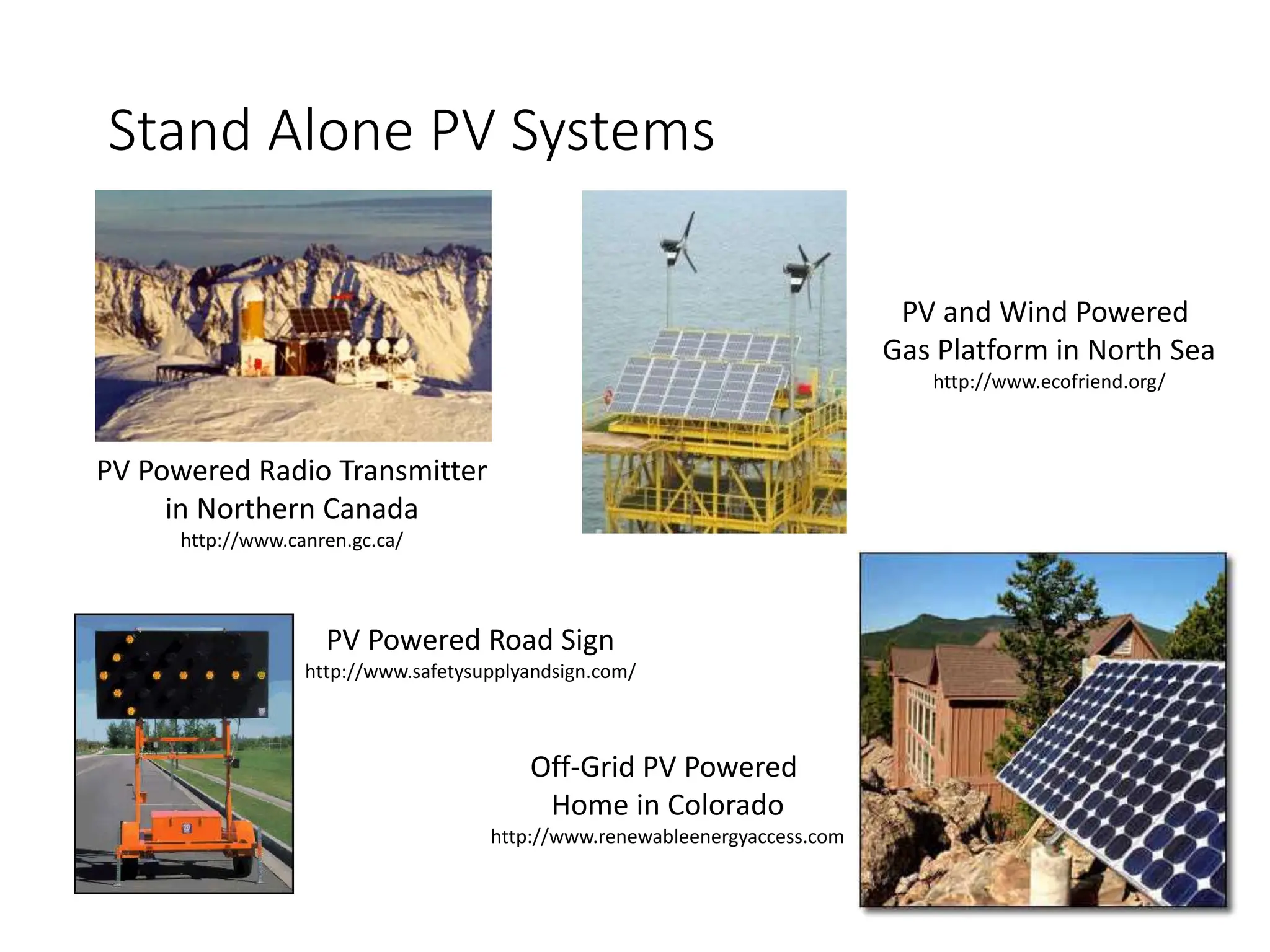

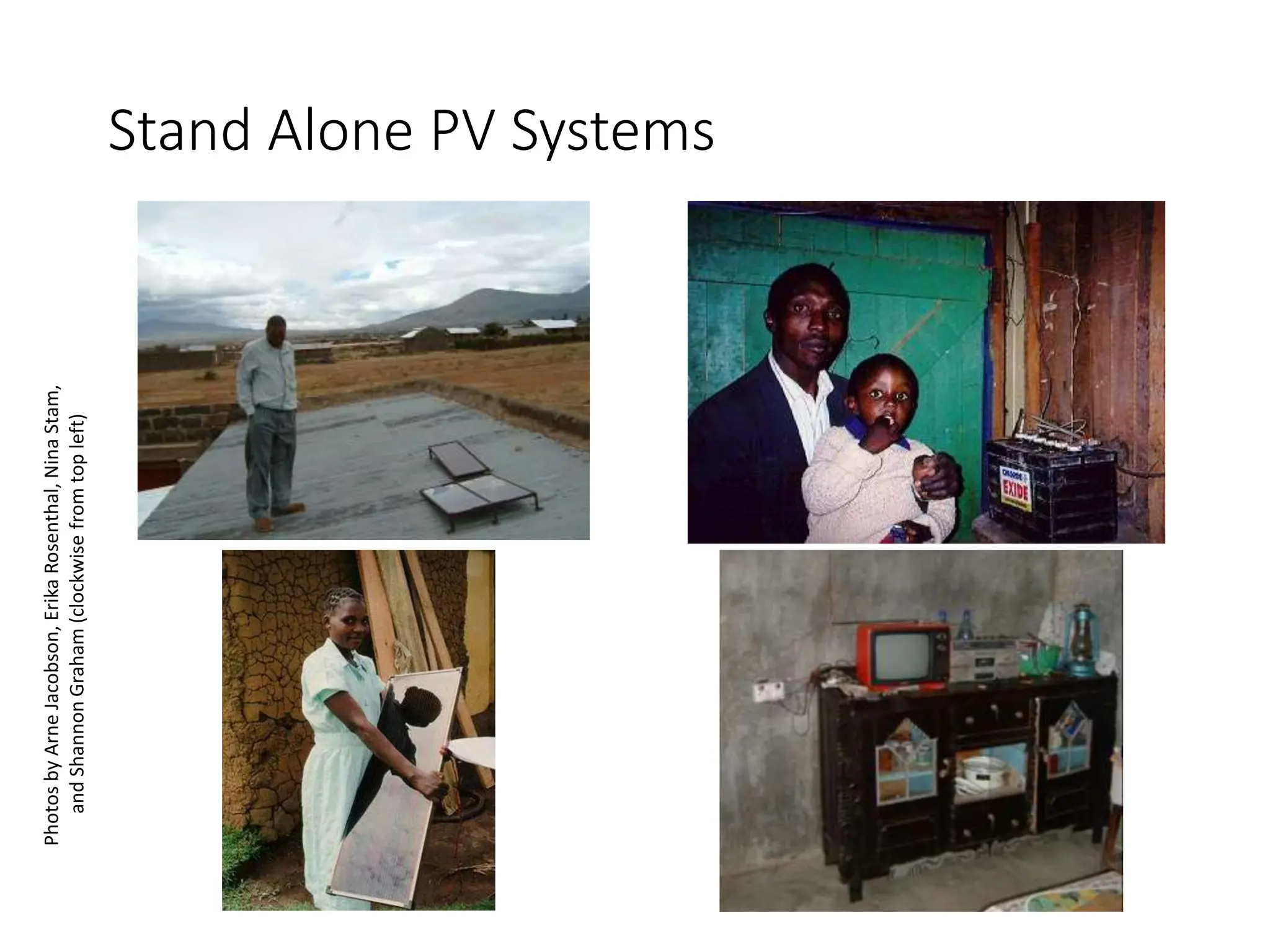

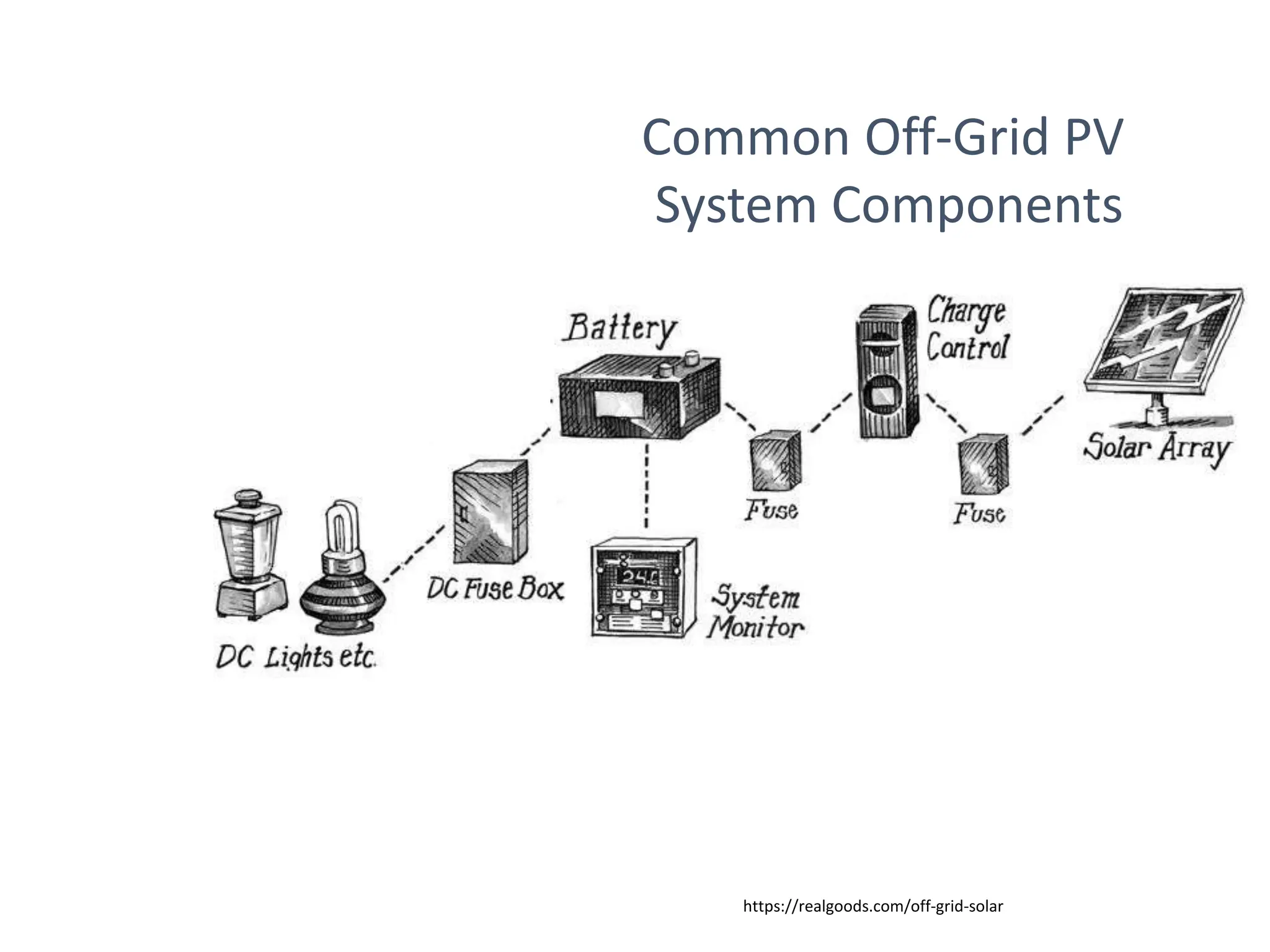

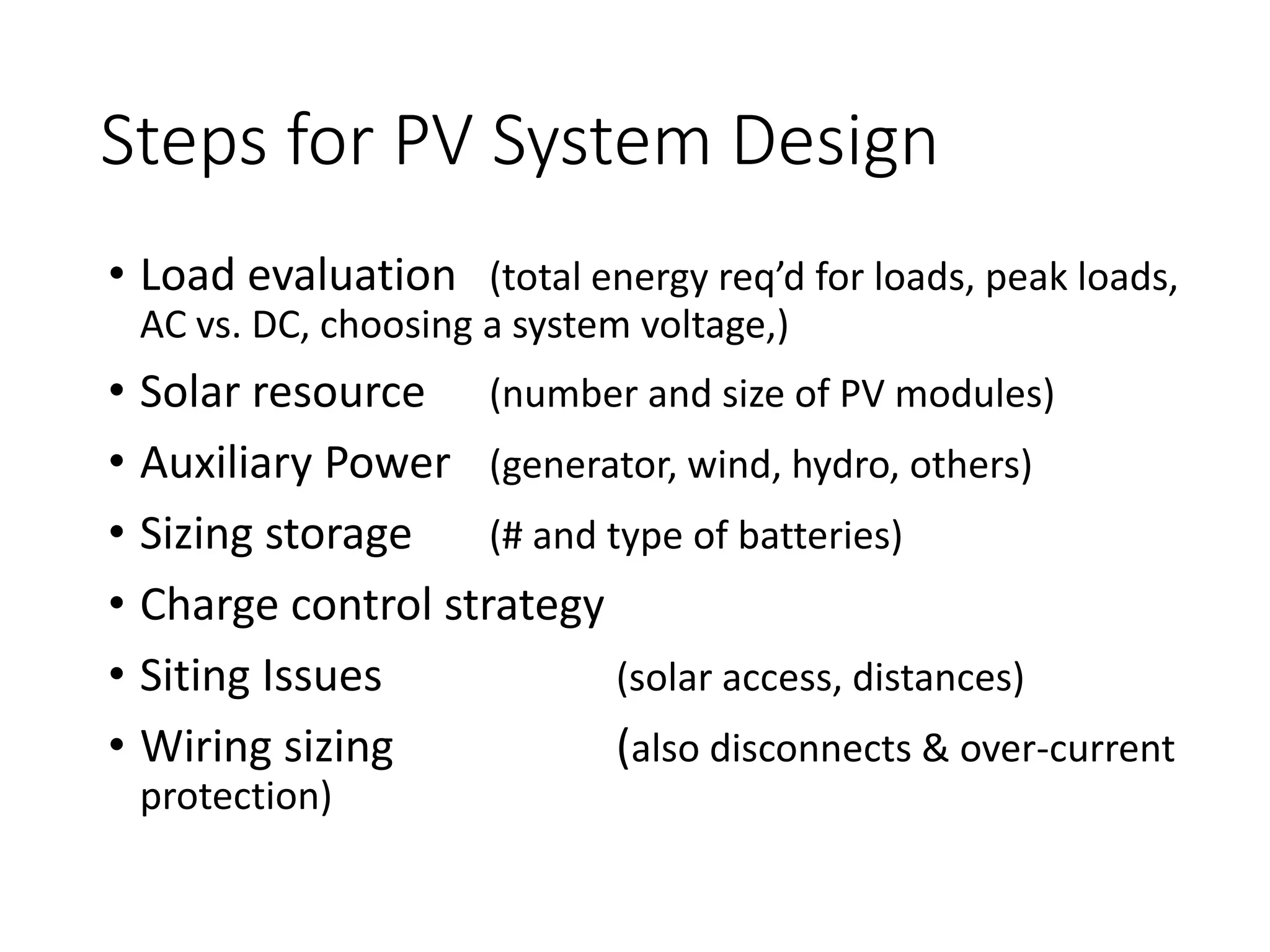

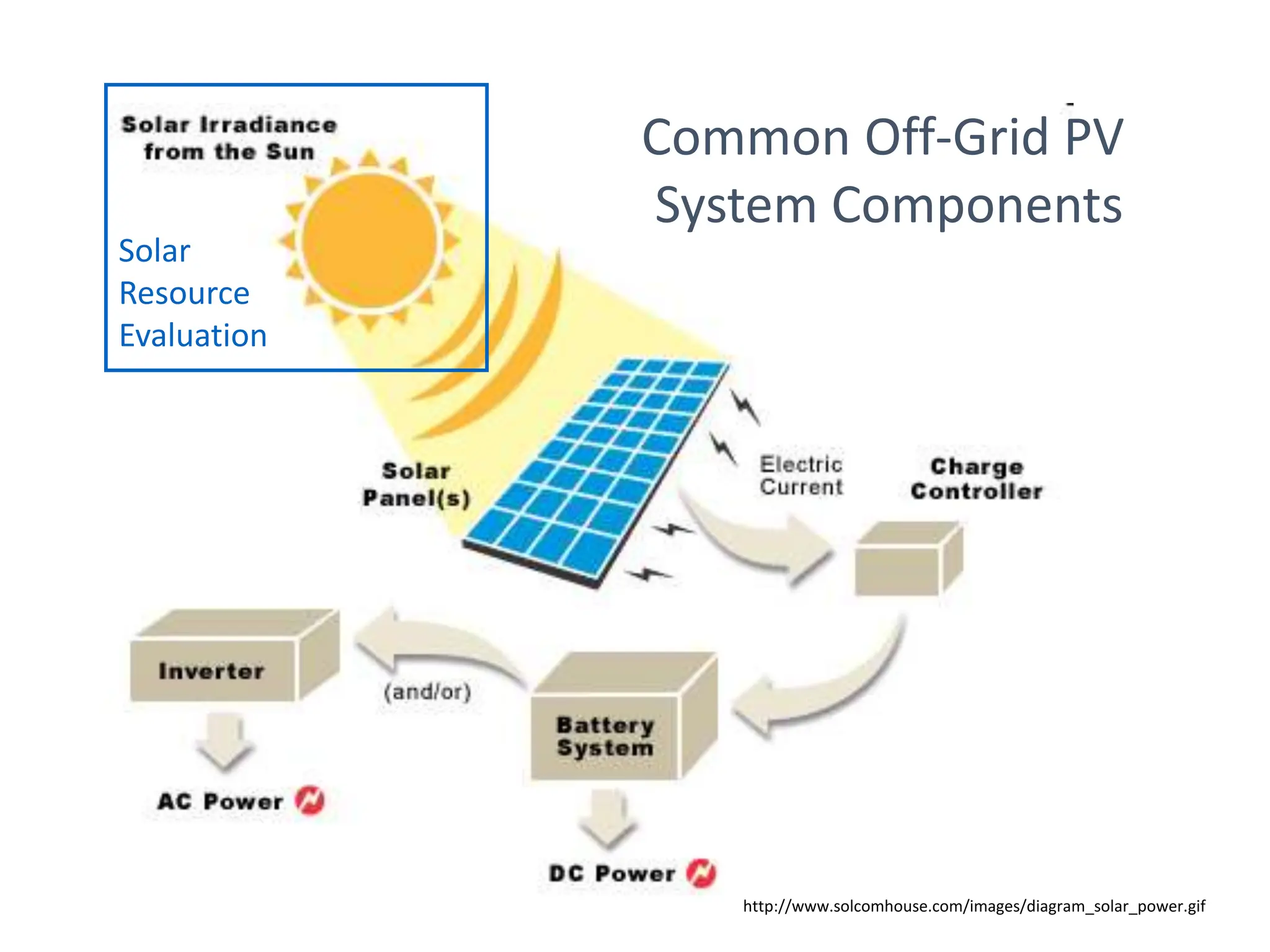

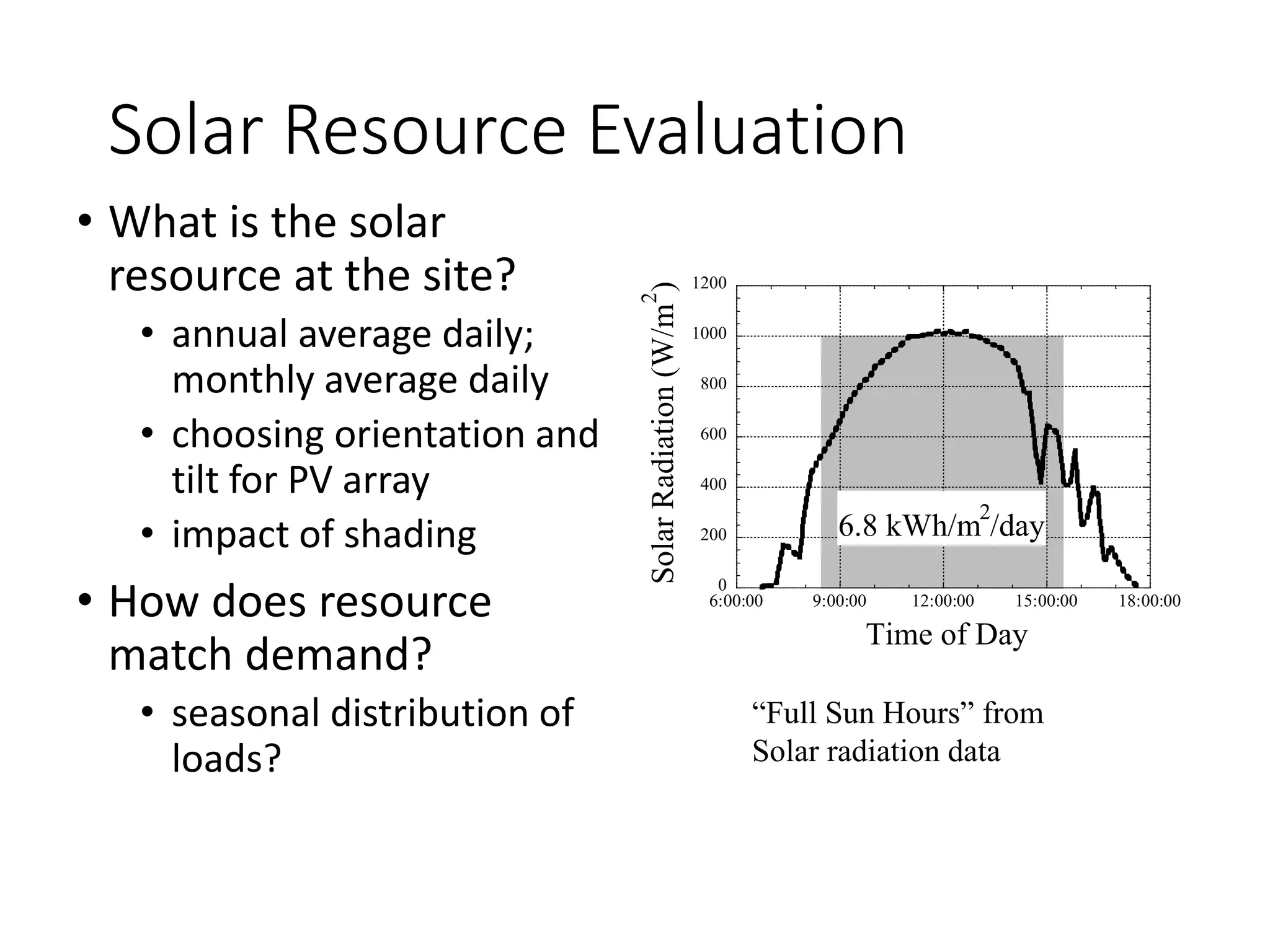

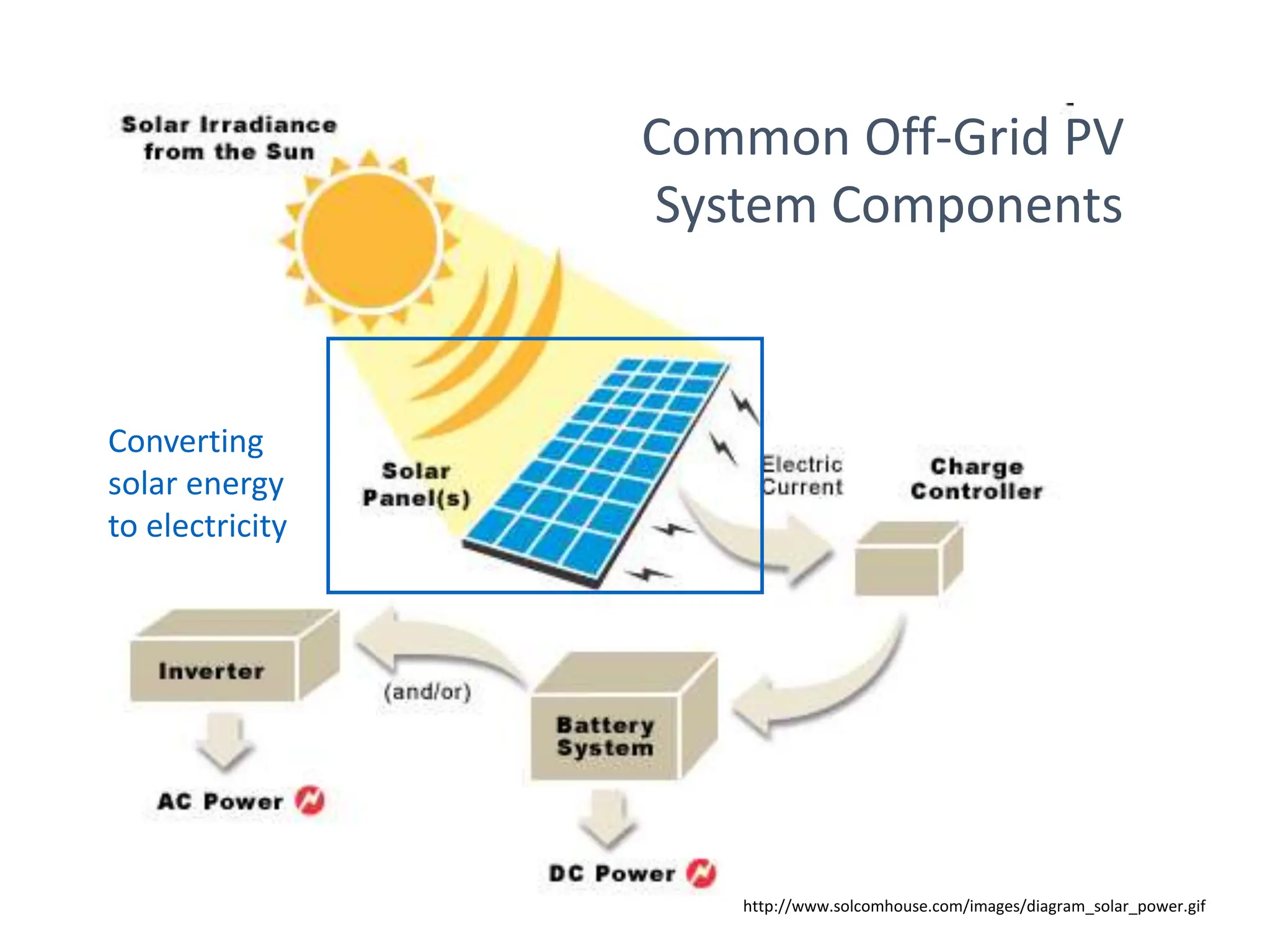

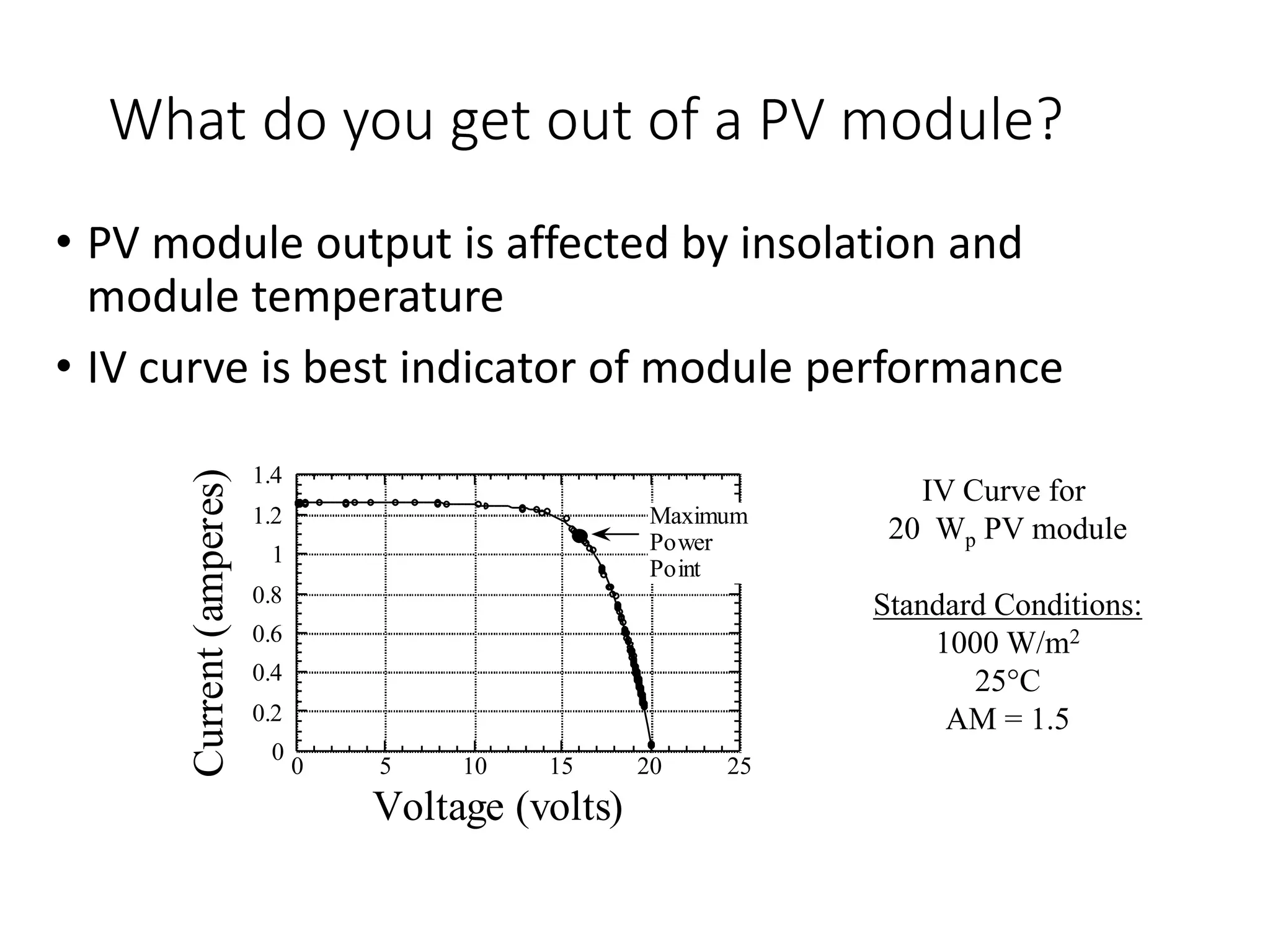

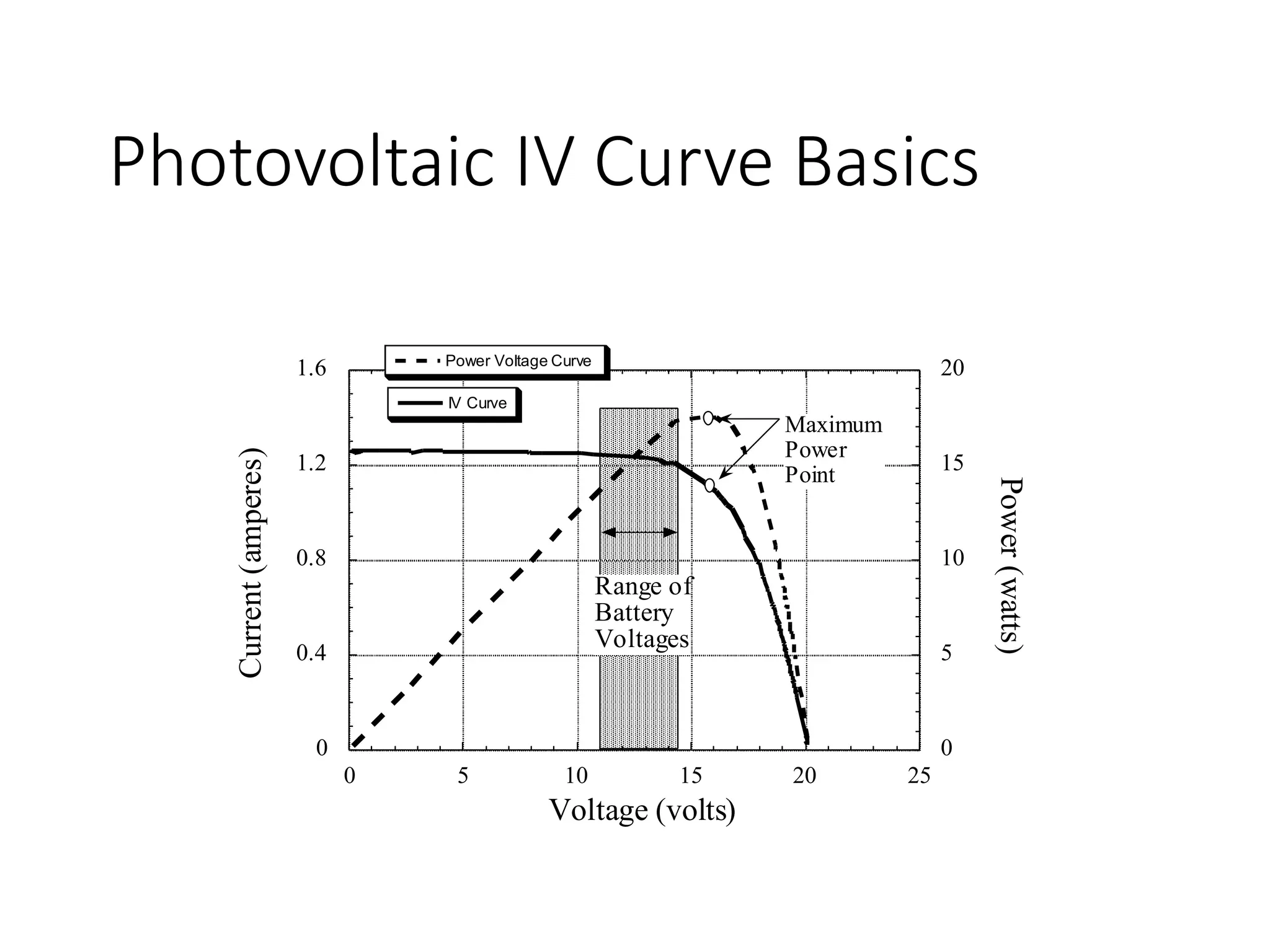

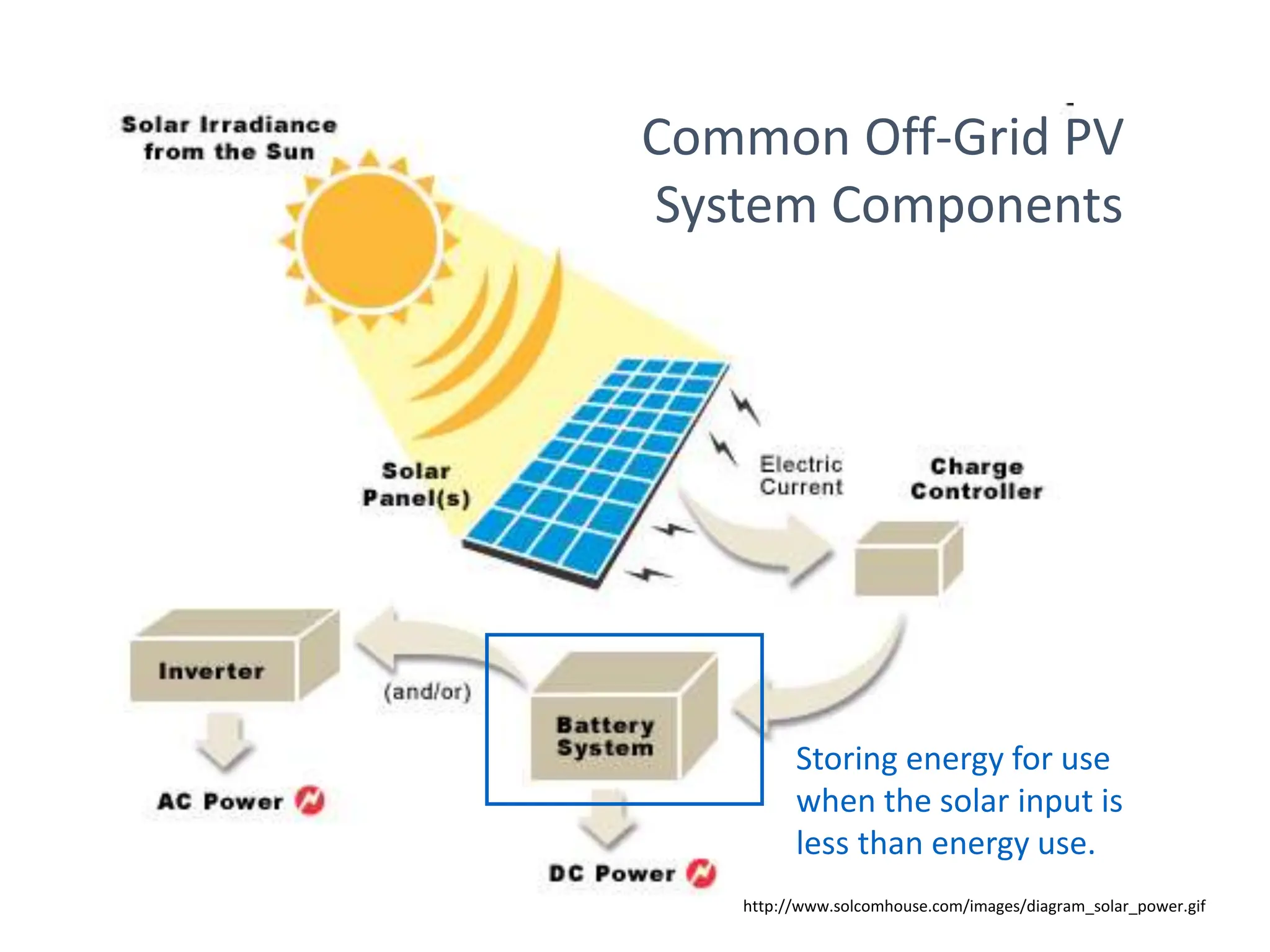

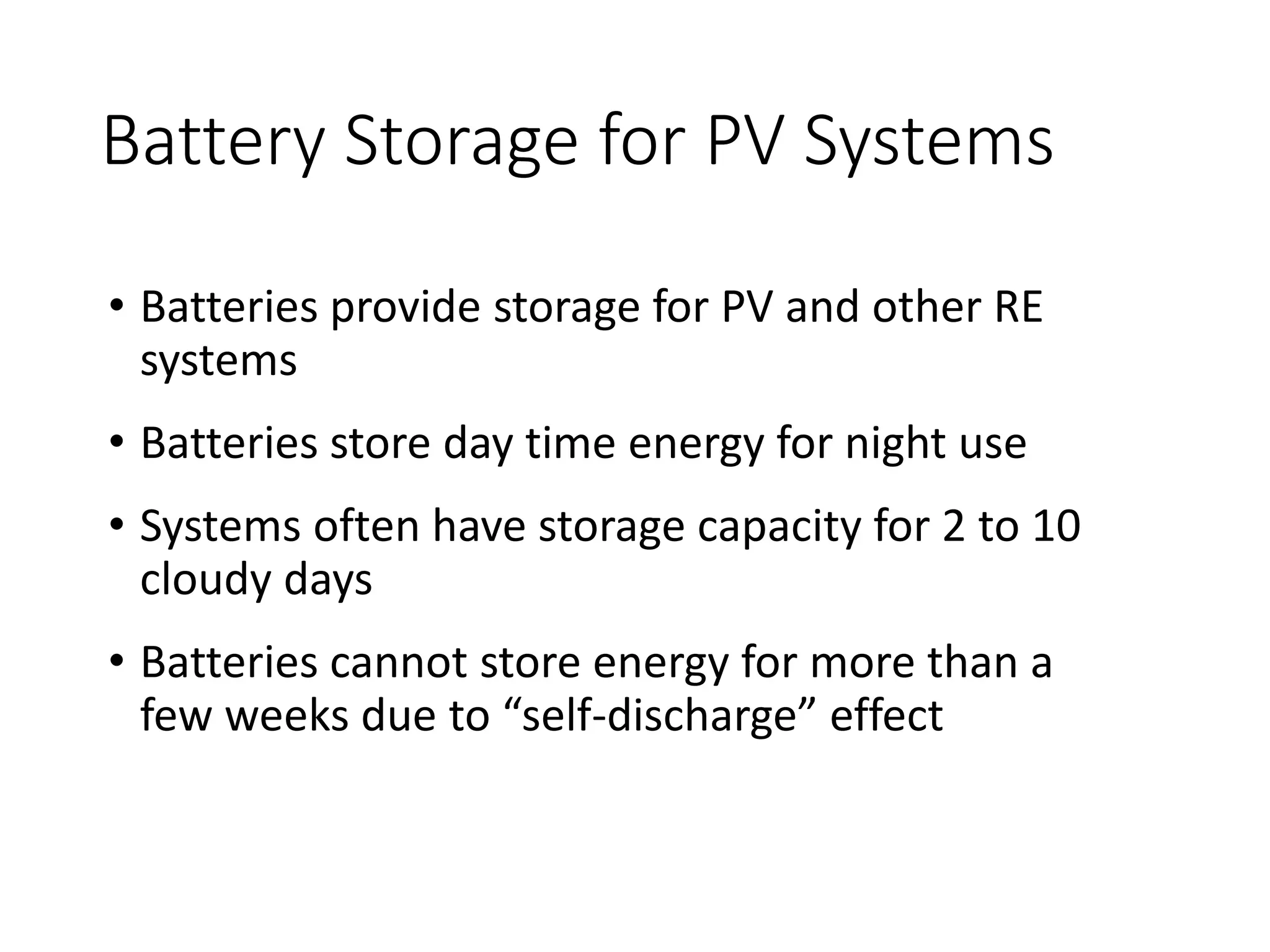

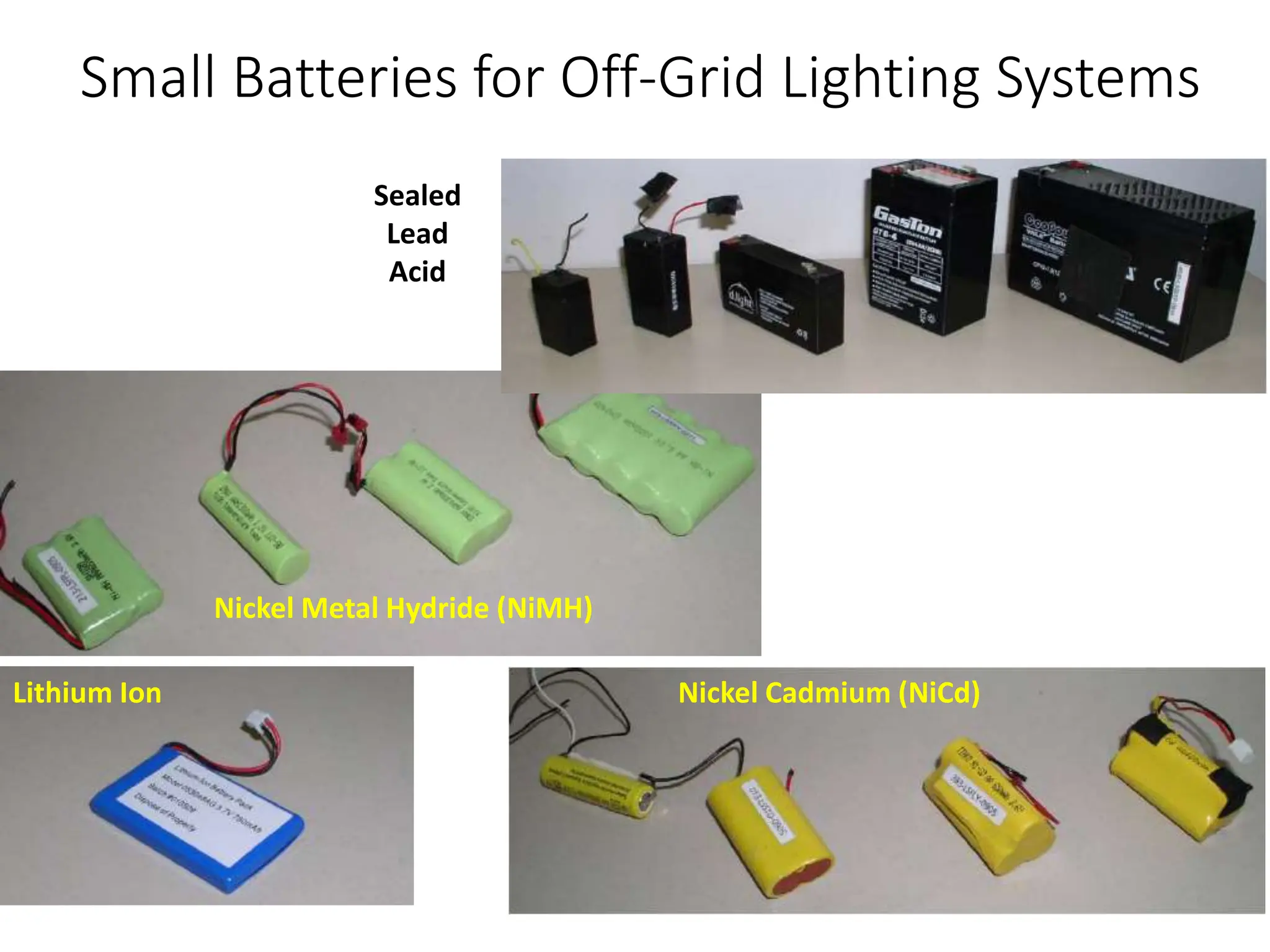

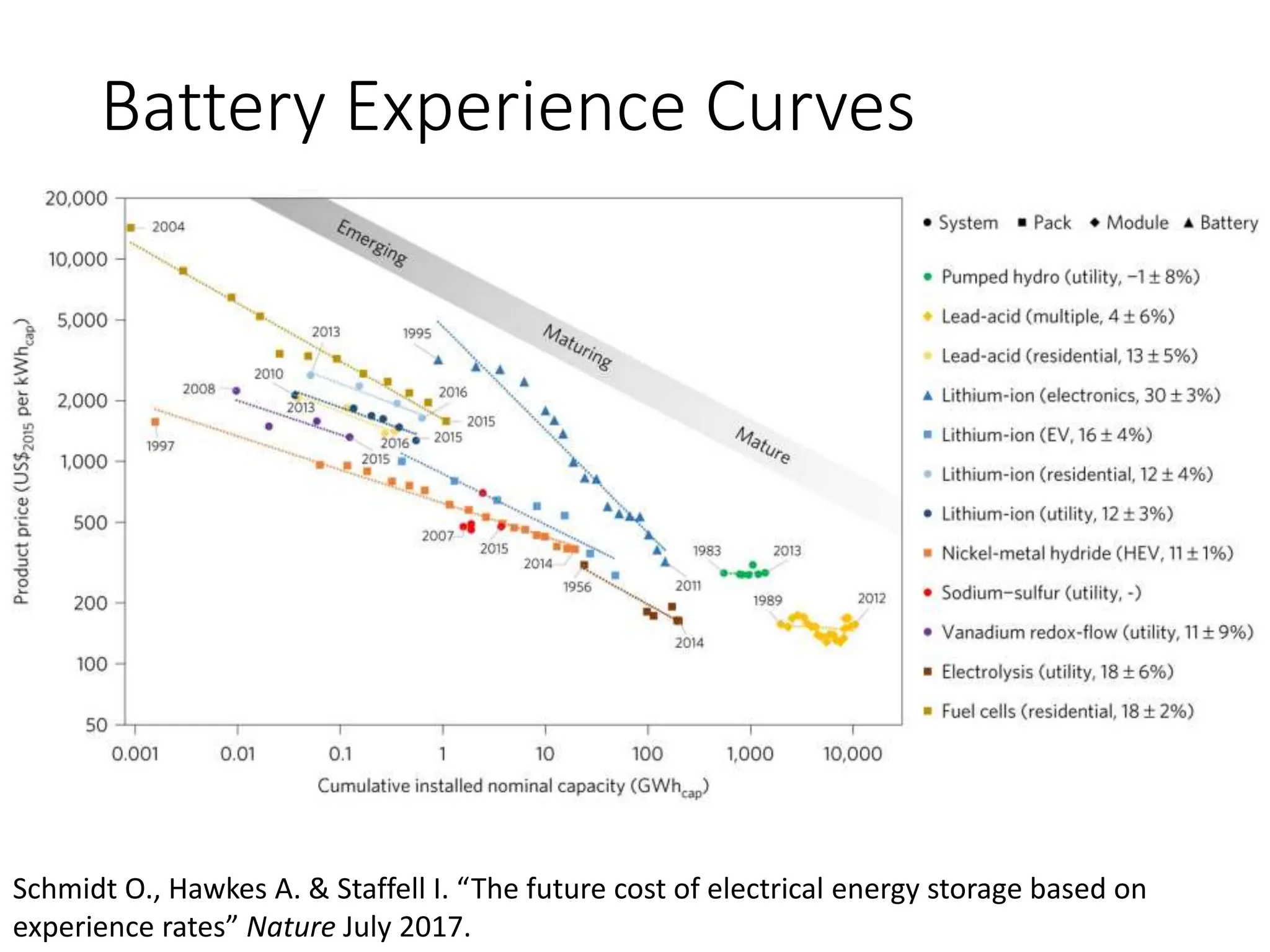

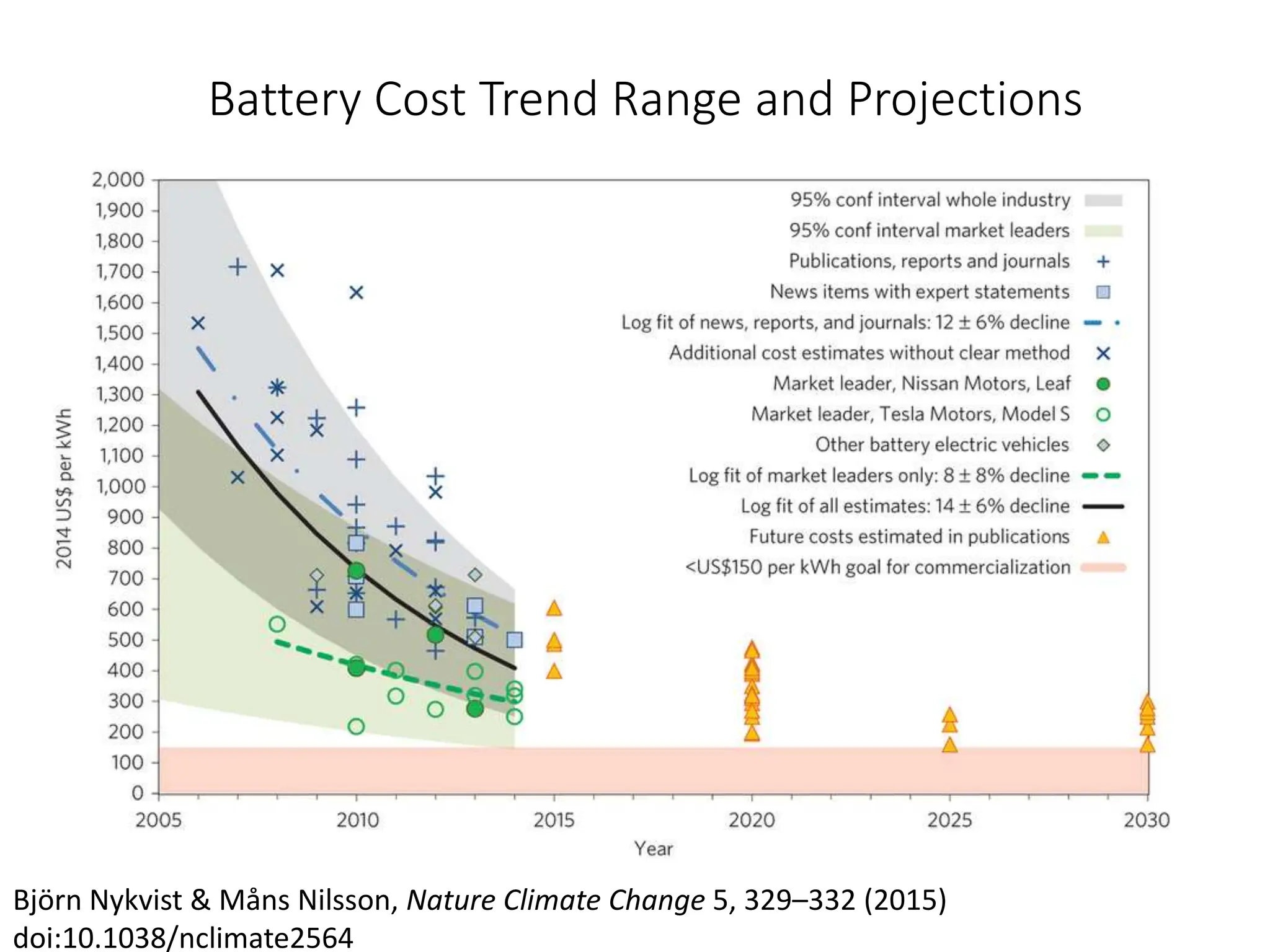

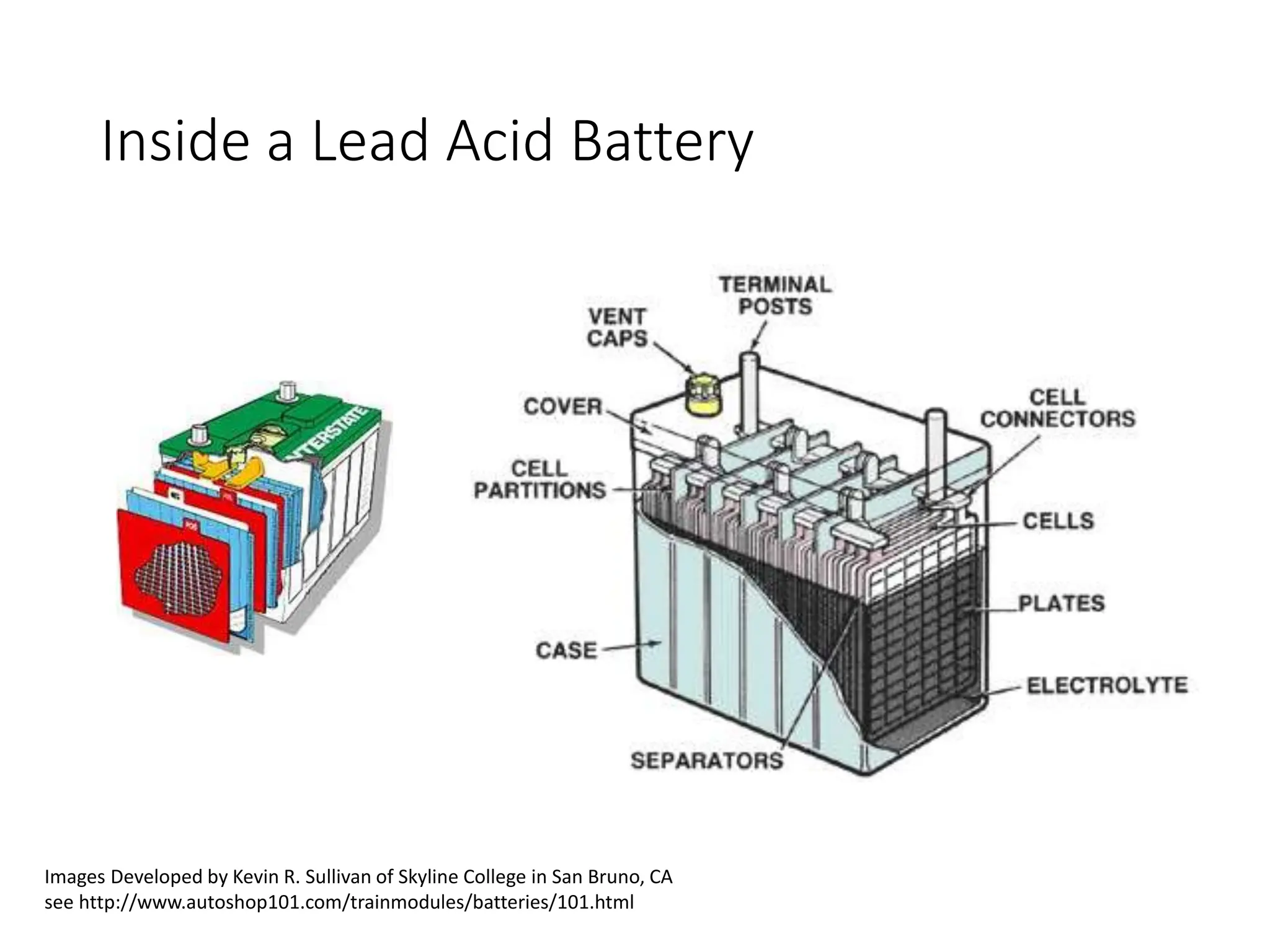

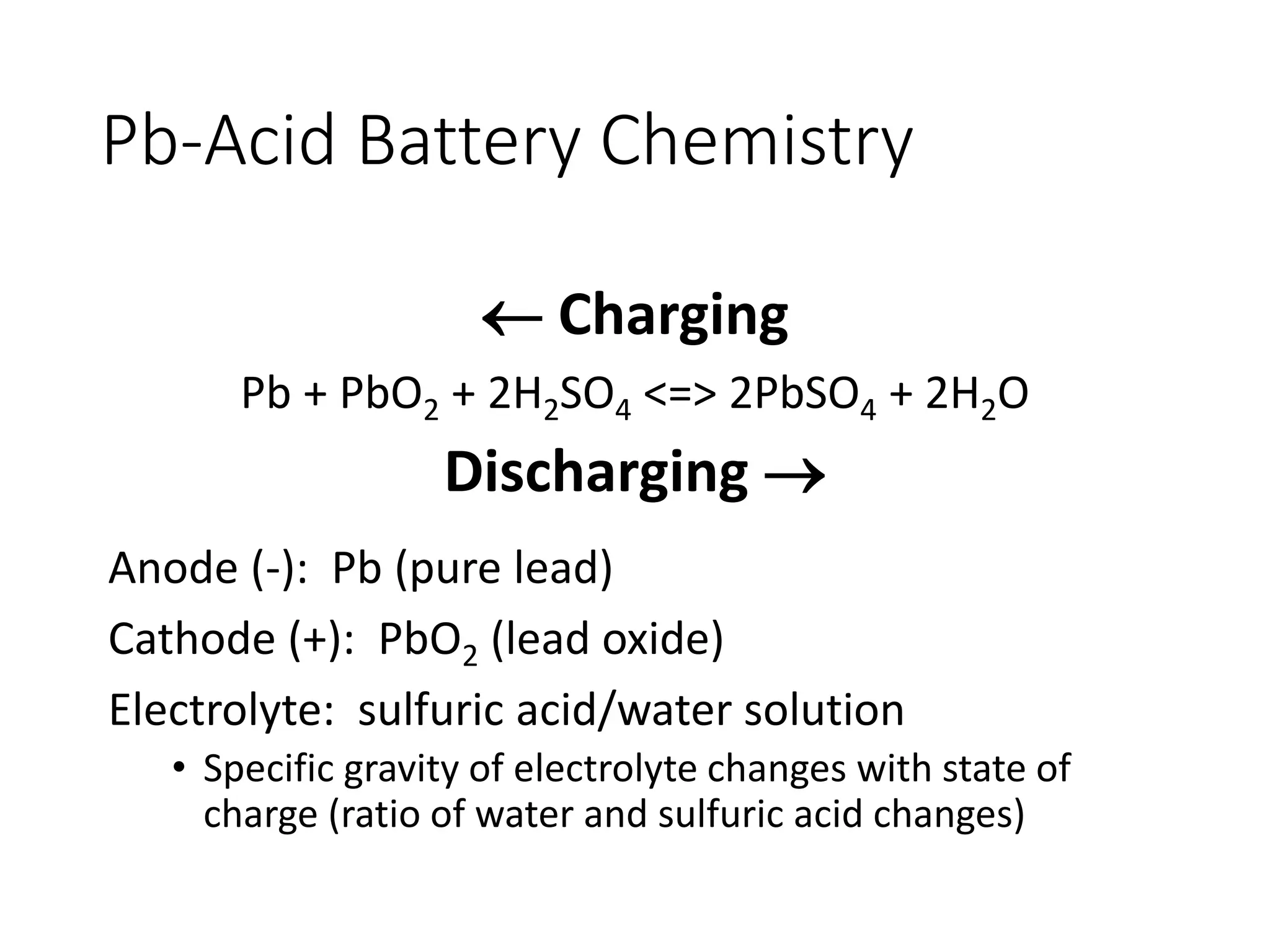

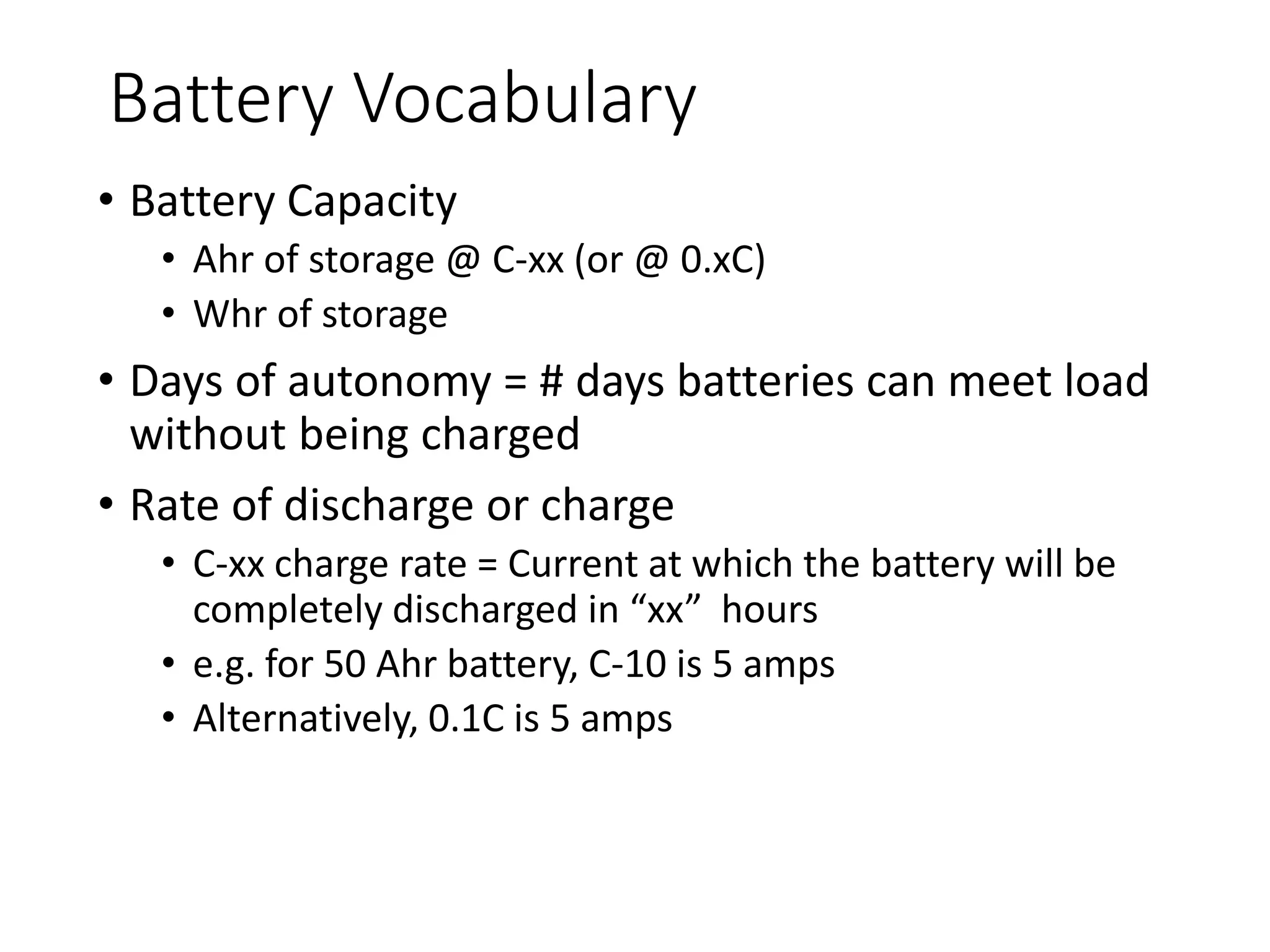

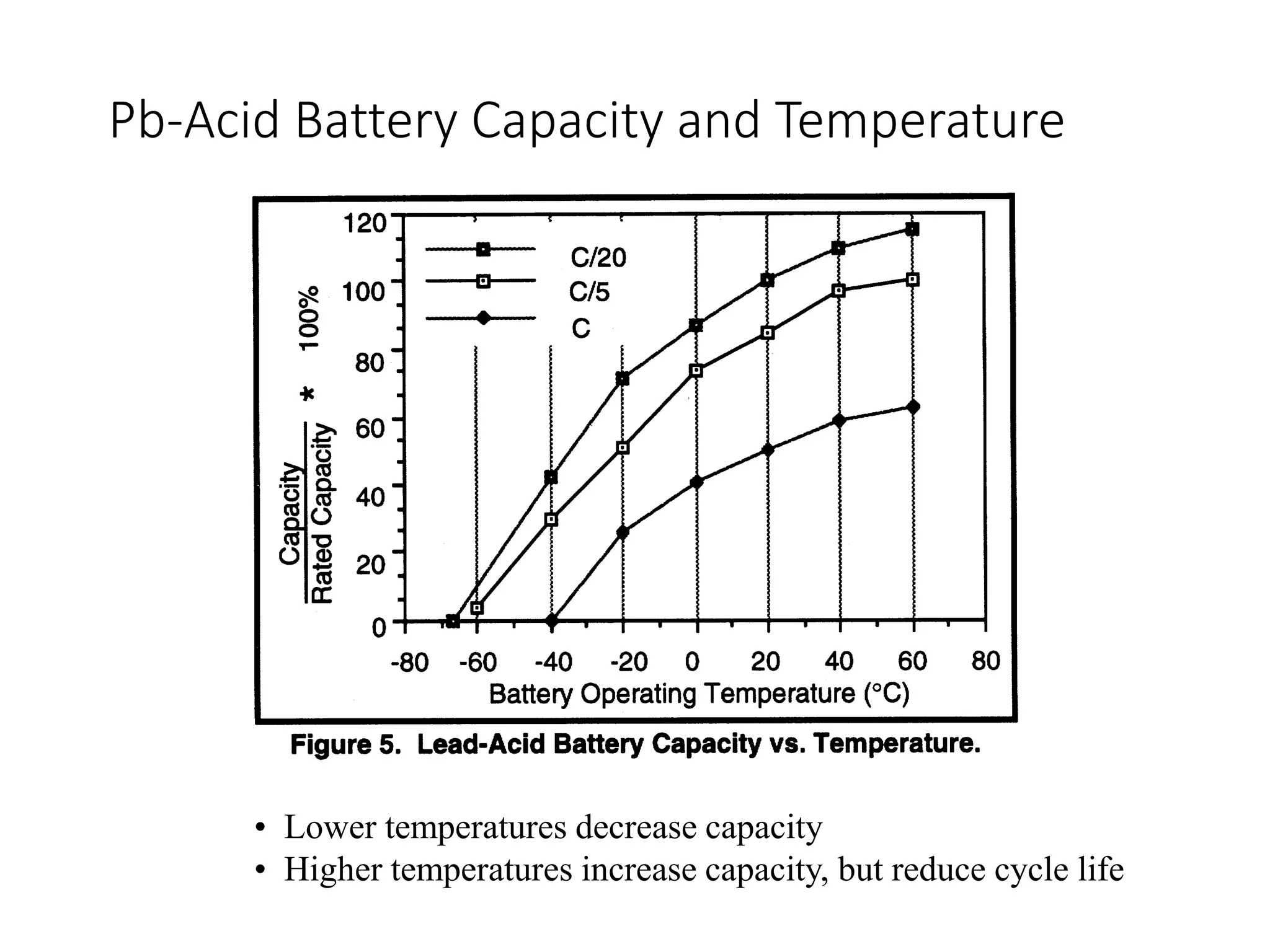

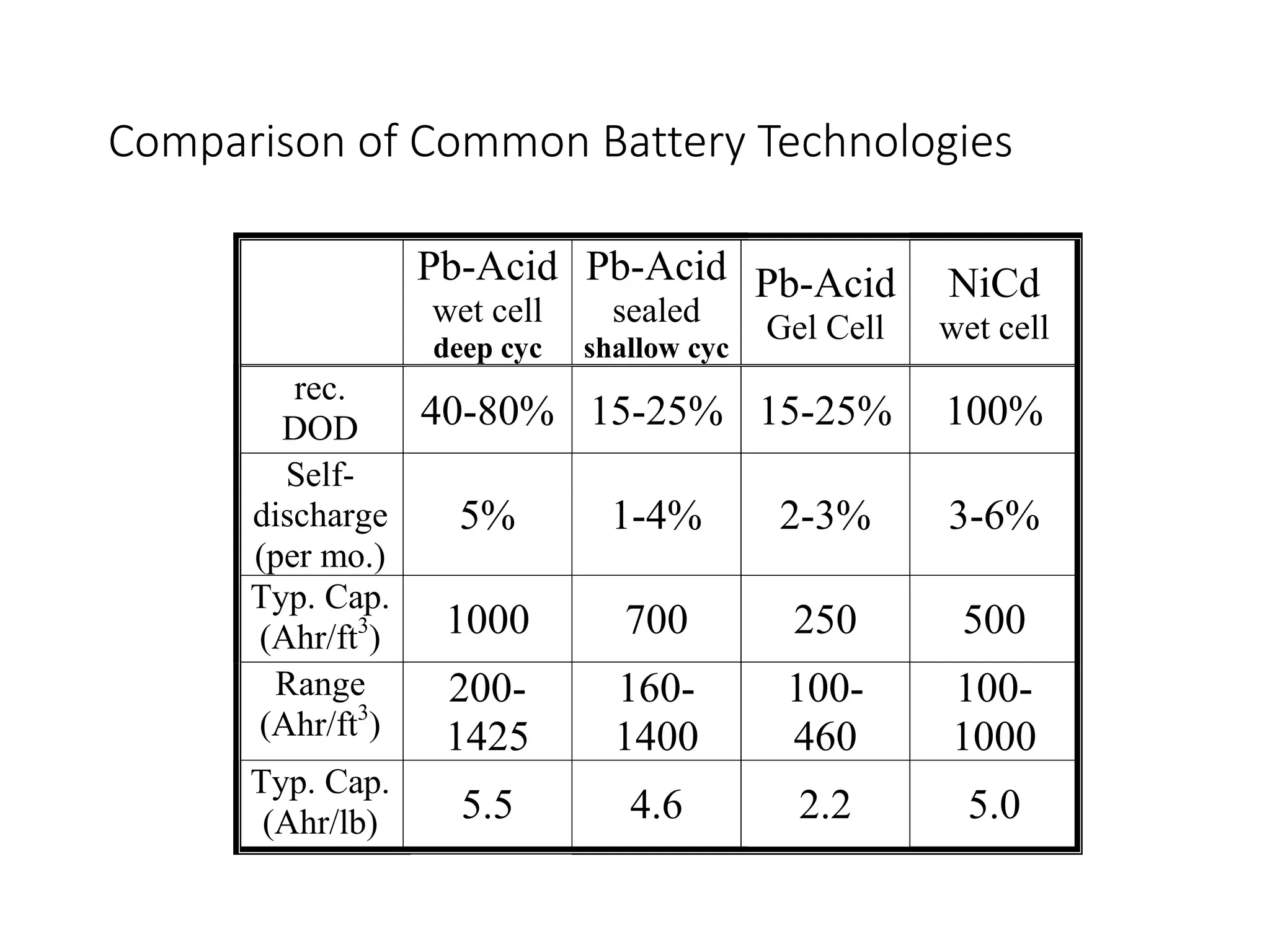

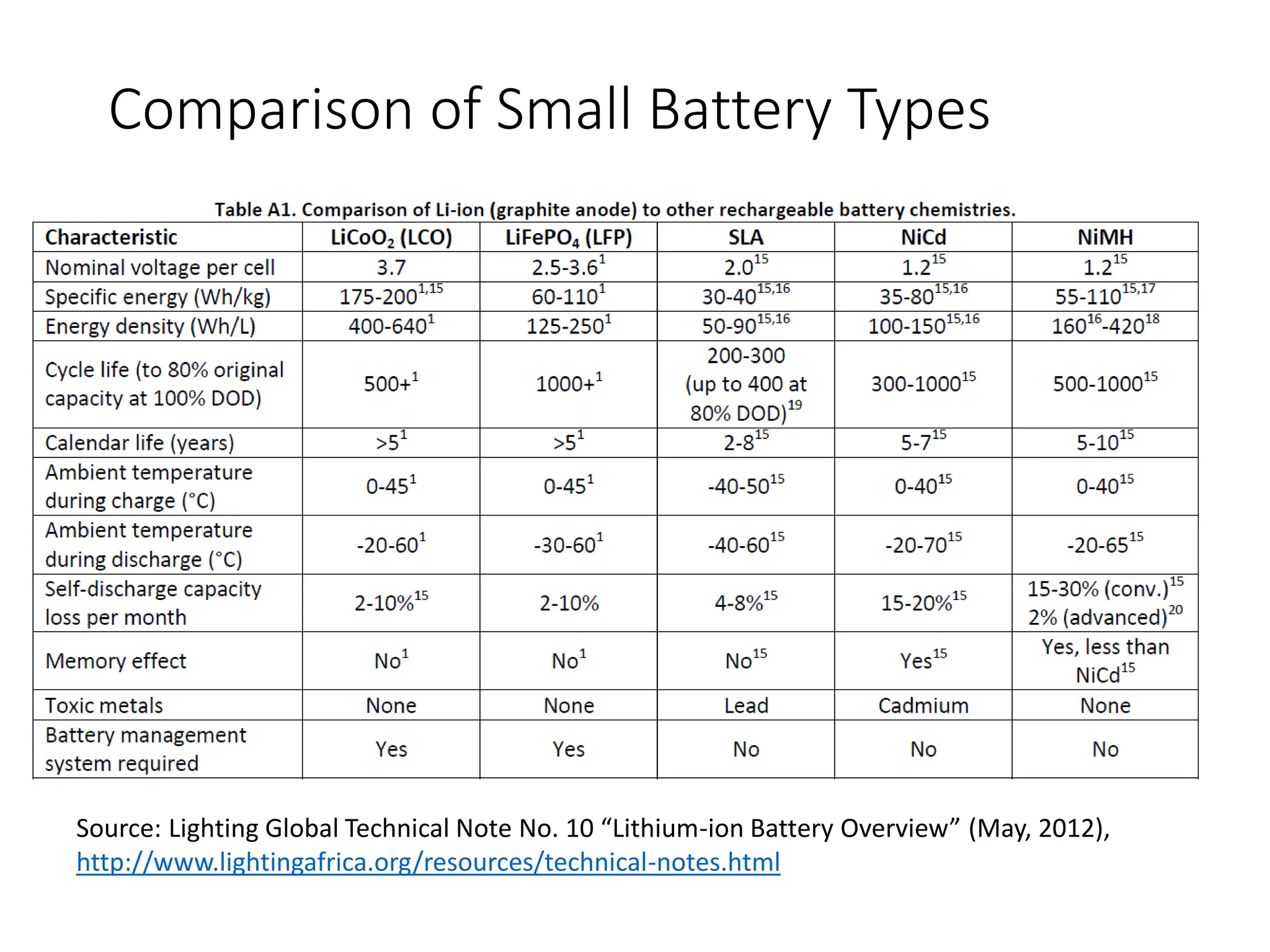

The document outlines the design principles and components of stand-alone photovoltaic (PV) systems, including the necessary components such as PV arrays, battery storage, and auxiliary power sources. It emphasizes the importance of load evaluation, solar resource assessment, and battery selection for optimizing system efficiency. Additionally, it covers the various types of batteries, their characteristics, and installation best practices for off-grid solar applications.

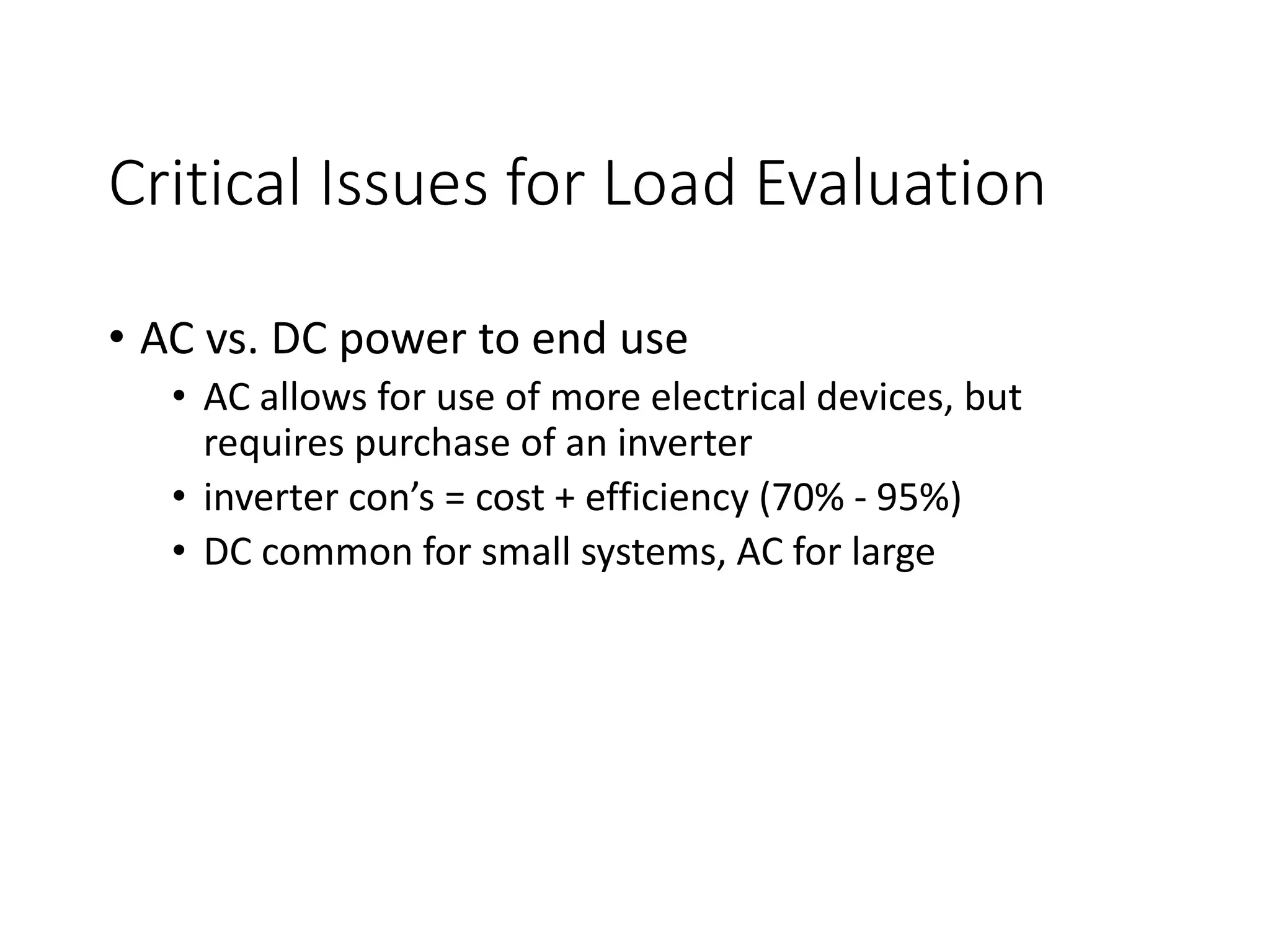

![Battery Sizing Calculations

AC Average Inverter + DC Average DC System = Average Amp-

Daily Load efficiency Daily Load voltage hours/Day

[( ) + ] =

Average X Days of Discharge Battery Ahr = Batteries in

Amp-hours/day Autonomy Limit Capacity Parallel

X =

DC System Battery = Batteries X Batteries = Total

Voltage Voltage in Series in Parallel Batteries

= X =

Battery Specification: Make: Model:](https://image.slidesharecdn.com/offgridpvdesignf19part1-240610190017-73474113/75/OffGrid_PV_Design_F19_part1-pptx-Lecture-from-Humboldt-State-University-46-2048.jpg)