This document details the Atterberg limit test, a laboratory experiment focused on determining the liquid limit, plastic limit, and plasticity index of fine-grained soils, critical for understanding soil behavior and engineering properties. It includes acknowledgments, procedures, a breakdown of apparatus and materials used, results, and discussions on findings related to soil consistency. The methods aim to classify soil types based on water content and their mechanical behavior in engineering contexts.

![Atterberg Limit Test February 21, 2020

Page 19 of 32

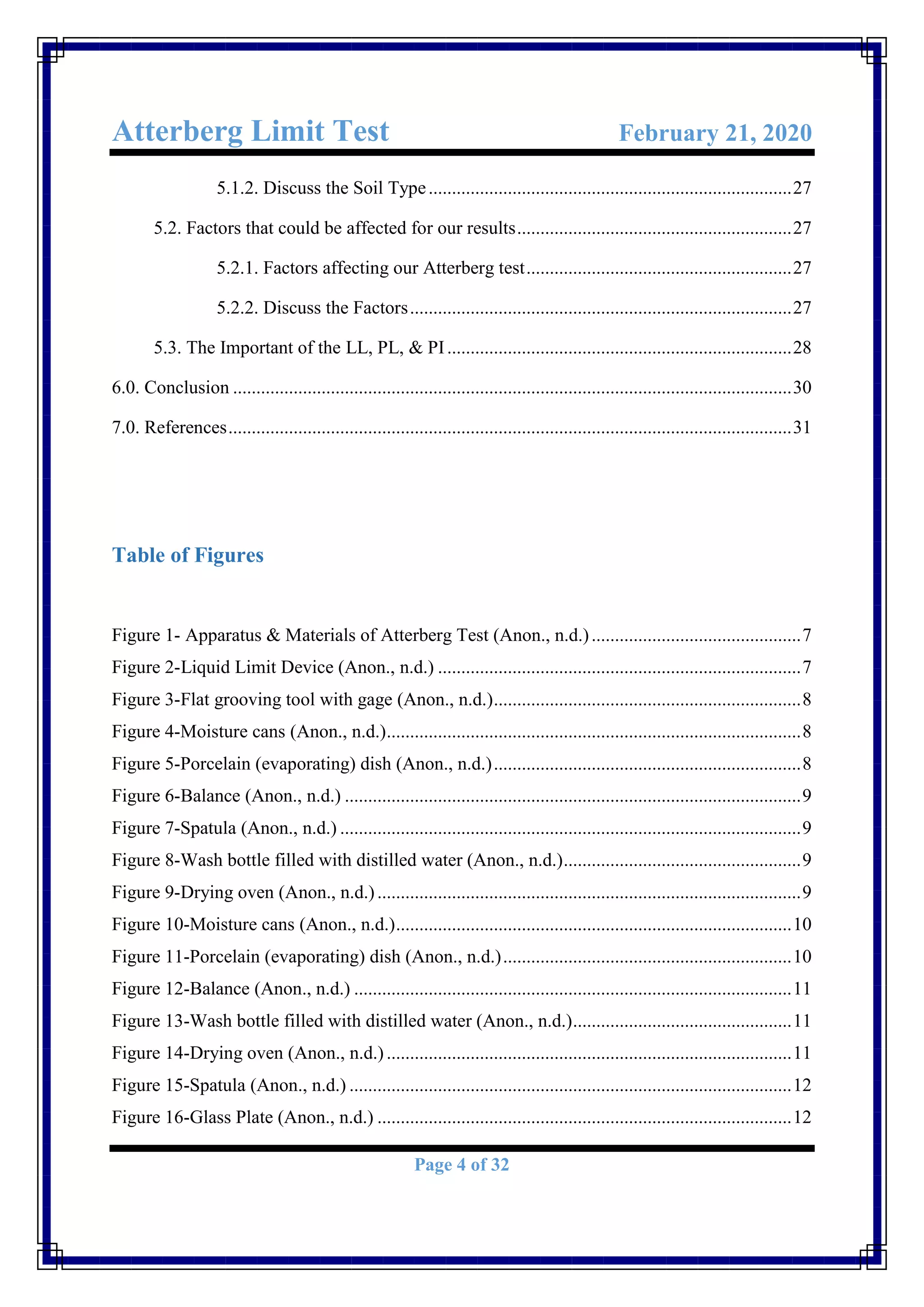

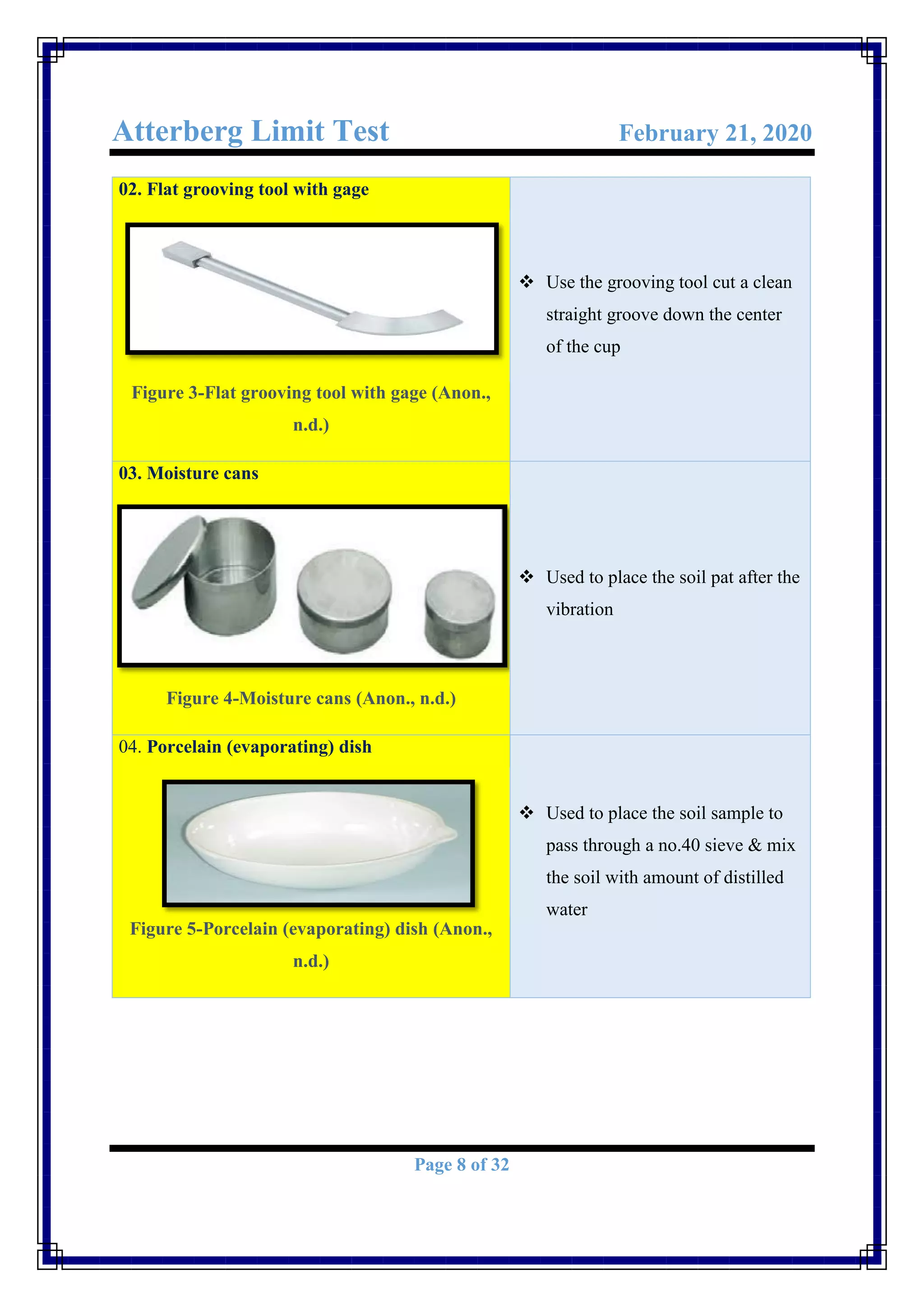

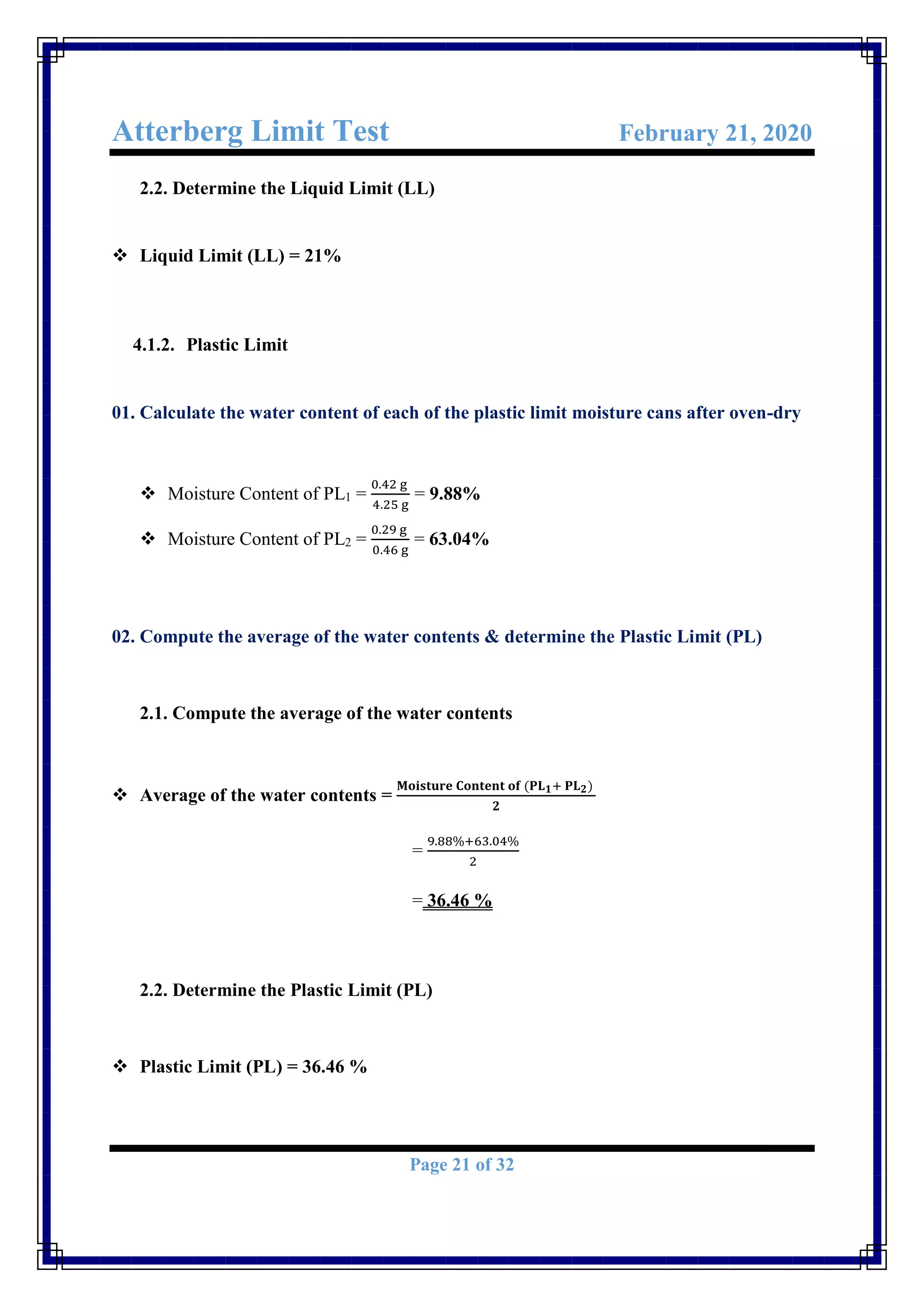

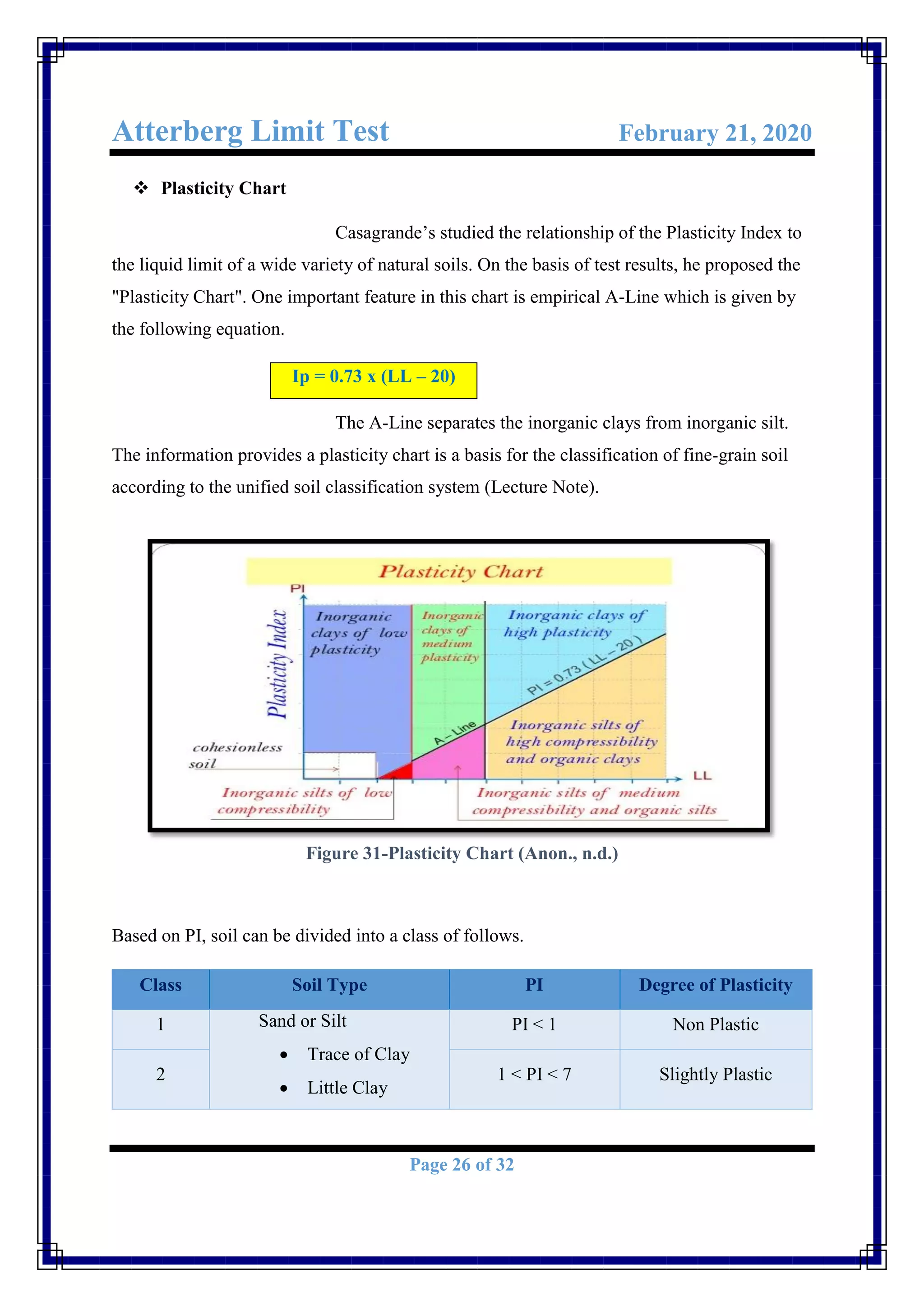

Wt. of Con

(g)

18.85 19.12 18.88 7.03 8.34

Wt. of Water

(g)

4.1 2.69 3.02 0.42 0.29

Wt. of dry

Soil (g)

19.79 12.23 14.02 4.25 0.46

Moisture

Content (%)

20.72 21.99 21.54 9.88 63.04

Wt. of Water (g) = [Wt. of Wet Soil + Con (g)] – [Wt. of dry Soil + Con (g)]

Wt. of dry Soil (g) = [Wt. of dry Soil + Con (g)] – Wt. of Con (g)

Moisture Content (%) =

𝐖𝐭.𝐨𝐟 𝐖𝐚𝐭𝐞𝐫 (𝐠)

𝐖𝐭.𝐨𝐟 𝐝𝐫𝐲 𝐒𝐨𝐢𝐥 (𝐠)

4.1.Calculation

4.1.1. Liquid Limit

01. Calculate the water content of each of the liquid limit moisture cans after oven-dry

Moisture Content of LL1 =

4.1 g

19.79 g

= 20.72%

Moisture Content of LL2 =

2.69 g

12.23 g

= 21.99%

Moisture Content of LL3 =

3.02 g

14.02 g

= 21.54%

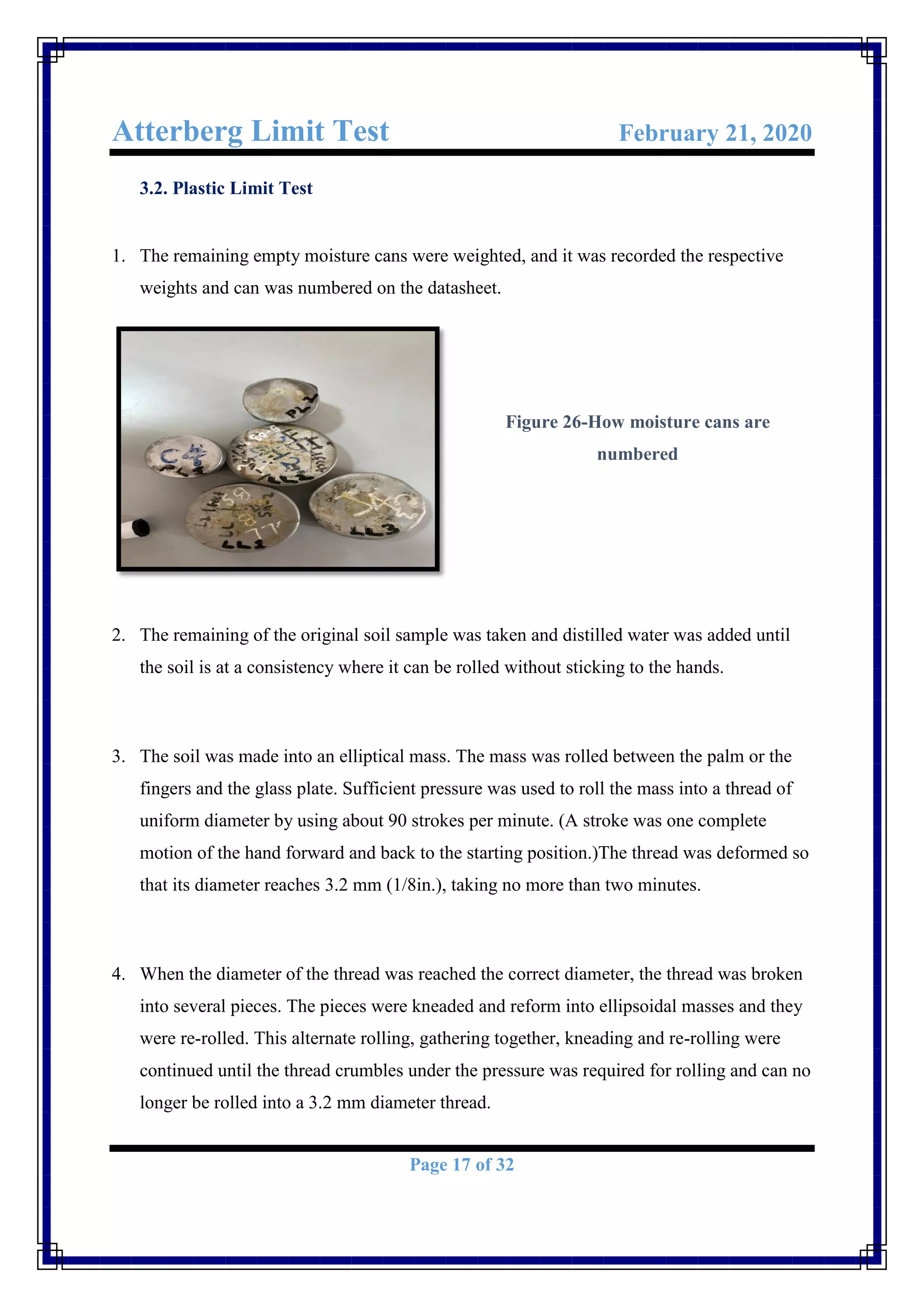

02. Draw the best-fit straight line for the liquid limit and determine the Liquid Limit

(LL)](https://image.slidesharecdn.com/atterberglimittest-copy-200702053343/75/Atterberg-Limit-Test-19-2048.jpg)

![Atterberg Limit Test February 21, 2020

Page 31 of 32

7.0. References

Anon., 2001. Determination of Atterberg Limits. [Online]

Available at:

http://www.rhd.gov.bd/Documents/ContractDocuments/StandardTestProcedures/Determi

nation%20of%20Atterberg%20Limits.pdf

[Accessed 05 2001].

Anon., n.d. Apparatus & Materials of Atterberg Test. [Online]

Available at:

https://www.google.com/search?q=Apparatus+%26+Materials+of+Atterberg+Test&clien

t=opera&hs=0So&source=lnms&tbm=isch&sa=X&ved=2ahUKEwiMz6Pck-

DnAhVCXHwKHUviBHgQ_AUoAXoECA0QAw&biw=710&bih=736

Anon., n.d. Atterberg Limits. [Online]

Available at: https://www.geoengineer.org/education/laboratory-testing/atterberg-limits

Anon., n.d. Atterberg Limits: A Quick Reference Guide. [Online]

Available at: https://www.globalgilson.com/blog/atterberg-limits-a-quick-reference-guide

Anon., n.d. Atterberg Limits: Determination of Plastic, Liquid, & Shrinkage Limits.

[Online]

Available at: https://civilseek.com/atterberg-limits/

Anon., n.d. Plasticity Chart. [Online]

Available at: https://image.slidesharecdn.com/lecture3consistncyofsoil-

161028162027/95/lecture-3-consistncy-of-soil-58-638.jpg?cb=1477671639

Buddhika, M., 2013. Atterberg limits test. [Online]

Available at: https://www.slideshare.net/malithwijaya1/atterberg-limits-test

[Accessed 11 09 2013].

Jajurie, N.-R., 2016. Lab Report #2: Liquid Limit, Plastic Limit, and Plasticity Index of

Soils. [Online]](https://image.slidesharecdn.com/atterberglimittest-copy-200702053343/75/Atterberg-Limit-Test-31-2048.jpg)

![Atterberg Limit Test February 21, 2020

Page 32 of 32

Available at:

https://www.academia.edu/28124222/Lab_Report_2_Liquid_Limit_Plastic_Limit_and_Pl

asticity_Index_of_Soils

[Accessed 8 March 2016].

Jamal, H., 2017. Atterberg Limits of Soil Classification. [Online]

Available at: https://www.aboutcivil.org/atterberg-limits.html

[Accessed 23 03 2017].

State Of New York, D. O. T., 2015. TEST METHOD FOR LIQUID LIMIT, PLASTIC

LIMIT, AND PLASTICITY INDEX. [Online]

Available at: https://www.dot.ny.gov/divisions/engineering/technical-services/technical-

services-repository/GTM-7b.pdf

[Accessed AUGUST 2015].](https://image.slidesharecdn.com/atterberglimittest-copy-200702053343/75/Atterberg-Limit-Test-32-2048.jpg)