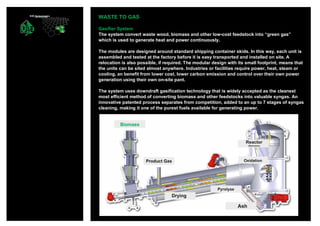

O2E Recycling Technologies has developed a patented gasification technology that converts waste wood and biomass into syngas, which can then be used to generate heat, power, steam, or cooling. The modular system is containerized for easy transport and installation. It uses downdraft gasification, which is considered the cleanest and most efficient method, along with an innovative process to produce one of the purest fuels available. Combined heat and power generators are used to produce electricity and thermal energy from the syngas. The goal is to create a sustainable closed-loop system to handle waste recycling and conversion needs.