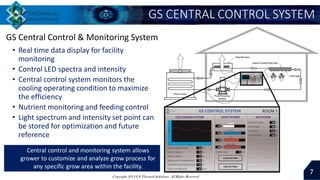

GS Thermal Solutions focuses on advanced cooling technology and energy-efficient grow systems tailored for indoor horticulture. Their proprietary liquid-cooled LED lighting systems enhance plant growth while reducing energy costs and carbon footprints. The company also offers a central control and monitoring system for facility optimization, enabling real-time data analysis and customization based on specific plant needs.